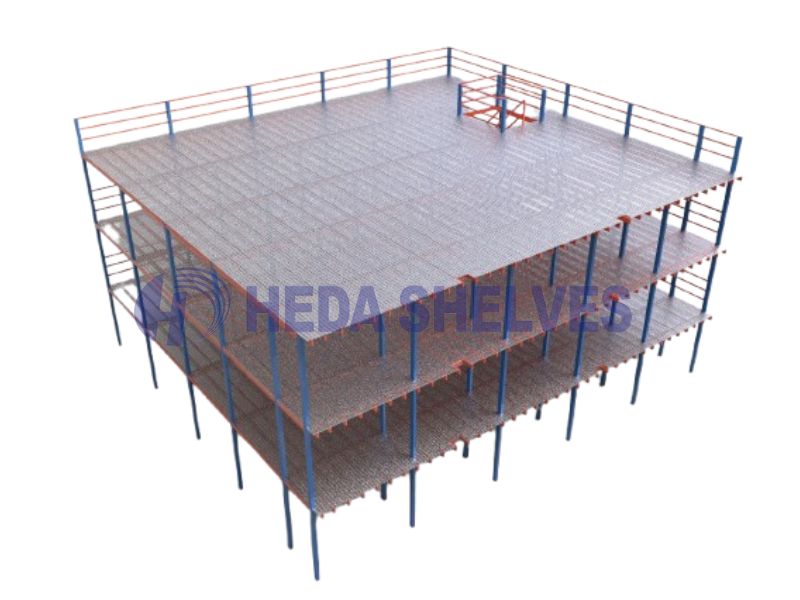

A mezzanine floor is one of the most effective ways to maximize vertical warehouse space without the cost of moving or constructing a new facility. It creates an intermediate level inside a building for storage, offices, or production. For distributors, e-commerce hubs, and manufacturers, mezzanines allow flexible expansion with minimal downtime.

However, selecting the wrong mezzanine system or overlooking critical design factors can lead to costly mistakes, safety hazards, and even compliance issues.

What Is the Weight Limit for a Mezzanine Floor?

Every mezzanine has a defined load-bearing capacity, usually measured in kilograms per square meter (kg/m²). This load rating ensures the structure can safely support people, equipment, and goods.

Standard light-duty mezzanines may support 250–350 kg/m², while heavy-duty warehouse mezzanines can be engineered for 500–1,000+ kg/m² depending on use. Exceeding these limits risks structural failure.

How Much Weight Can a Warehouse Mezzanine Floor Hold?

The answer depends on the design standard and intended use. For example:

- Storage of light cartons or shelving: ~300 kg/m²

- Palletized goods or machinery: 500–1,000 kg/m²

- Office use or personnel access: 250–350 kg/m²

Professional manufacturers design mezzanines according to international codes such as EN 1991, ANSI MH28.3, or local building regulations. Always request a stamped engineering report before installation.

Pallet Racking vs Mezzanine Floor

While pallet racking maximizes vertical storage for pallets, a mezzanine creates an entire additional floor area. The two systems can also work together: a rack-supported mezzanine combines structural racking uprights with elevated flooring, providing both pallet storage and accessible workspace. Choosing between them depends on operational needs—racking is best for bulk pallet handling, while mezzanines suit mixed storage, picking, and office integration.

Mistakes of Mezzanine Kits Design (Top 10 Pitfalls to Avoid)

1. Ignoring Weight Limits

Overloading a mezzanine is one of the fastest ways to compromise safety. Many buyers underestimate the actual load of pallets, forklifts, or shelving systems. Always calculate live and dead loads precisely.

2. Skipping Safety Measures

Handrails, toe boards, safety gates, and anti-slip flooring are not optional. OSHA and local regulations mandate them for worker protection. Cutting corners here leads to accidents and liability issues.

3. Forgetting About Lighting

A mezzanine can cast shadows on the floor below, creating dark, unsafe areas. Poor visibility reduces productivity and increases risks during forklift or picking operations. Plan for integrated LED lighting systems both above and below the structure.

4. Neglecting Fire Safety

Fire sprinklers, smoke detectors, and fire-rated materials are often overlooked. Most jurisdictions require mezzanine floors to integrate with the building’s fire protection system.

5. Using the Wrong Flooring Material

Not all floor panels are equal. Chipboard may be cost-effective but absorbs moisture. Steel grating provides ventilation but is noisy. Choose materials based on intended use: office areas need smooth laminate, while industrial zones may require galvanized steel.

6. Not Considering Ventilation

Enclosed mezzanines trap heat and dust. Lack of airflow creates uncomfortable working conditions and may violate occupational safety standards. Incorporate ventilation or fans into the design.

7. Creating a Dead Zone Underneath

Some mezzanines are poorly planned, leaving awkward, unusable spaces beneath. The underside should be designed for racking, workstations, or forklift aisles to maximize ROI.

8. Forgetting About Maintenance

Like any structure, mezzanines require inspections. Loose bolts, worn flooring, or corrosion must be addressed early. Neglecting maintenance shortens lifespan and increases risks.

9. DIY Electrical Work

Running cables or lighting without licensed electricians is dangerous and often illegal. Electrical integration should be part of the professional mezzanine installation package.

10. Ignoring Building Codes

Local codes regulate mezzanine size, egress, safety barriers, and fire protection. Failing to comply can lead to fines, forced removal, or legal action. Always verify compliance with certified engineers.

Load Standards & Storage

International mezzanine design follows strict standards:

- EN 1090 & EN 1991 (Europe)

- ANSI MH28.3 (U.S.)

- AS 1657 (Australia)

Storage type determines the load class: light shelving, medium carton flow, or heavy pallet zones. Correct classification ensures efficiency and safety.

Investing in a mezzanine floor is not just a construction project—it is a business growth strategy. By expanding vertically, companies save on relocation, lease, and land costs. The ROI of a professionally designed mezzanine often exceeds 200% within 3 years, especially for e-commerce, 3PL, and manufacturing firms.

Conclusion

A mezzanine floor can double your usable space and improve workflow, but only if designed correctly. Ignoring weight limits, safety, and compliance can turn an investment into a liability. Partner with a professional mezzanine manufacturer who provides engineering support, compliance documentation, and turnkey installation.

At HEDA SHELVES, we deliver custom mezzanine racking systems engineered to international standards, ensuring safety, efficiency, and long-term storage to your warehouse operations.