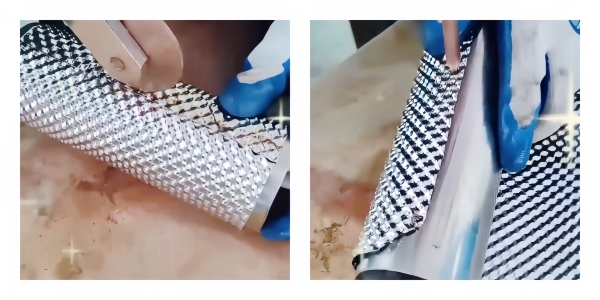

Our Exhaust Muffler Packing is engineered for superior sound absorption, extreme temperature resistance, and long-lasting durability. Designed for use in high-performance exhaust systems—including motorcycles, ATVs, dirt bikes, cars, and industrial silencers—our packing materials reduce exhaust noise while maintaining optimal airflow and exhaust backpressure.

Key Features

-

High-Temperature Resistance

Withstands continuous temperatures up to 1000°C (1832°F) depending on material type (Fiberglass, Ceramic Fiber, or Basalt), ensuring long-term performance in extreme exhaust environments. -

Excellent Sound Deadening

Effectively reduces exhaust noise by dampening sound waves and vibrations inside the muffler. Ideal for racing, off-road, and street applications. -

Available in Multiple Materials

Choose from Fiberglass, Ceramic Fiber, or Basalt Fiber packing to match your performance needs, temperature requirements, and budget. -

Easy to Use & Custom Fit

Our packing can be cut and shaped to fit virtually any muffler canister. Compatible with most aftermarket and OEM exhaust systems. -

Long-Lasting Durability

Maintains shape and performance over time without excessive blow-out or degradation, minimizing repack frequency.

Applications

-

Motorcycle and Dirt Bike Mufflers

-

ATV and UTV Exhausts

-

Automotive Performance Exhaust Systems

-

Industrial Silencer Repacking

-

Off-Road and Racing Vehicles

Why Choose Our Muffler Packing?

OEM-Quality Materials

Tested for Real-World Performance

Excellent Thermal Insulation

Fast Global Shipping

Wholesale and Custom Sizes Available

Optimize Your Exhaust Performance

Whether you're repacking a blown-out motorcycle muffler or upgrading an automotive exhaust system, our high-performance exhaust muffler packing delivers the perfect balance of noise control, heat resistance, and durability.

Contact us today to request a sample, bulk pricing, or technical support. We offer customized solutions for dealers, workshops, and performance parts distributors

Revolutionize Exhaust Performance with Patented Embossed Stainless Steel Heat Shield

Our patented embossed stainless steel heat shield represents a breakthrough in thermal management technology, engineered to deliver unmatched protection and performance for exhaust systems. Unlike conventional solutions, the precision-engineered embossing pattern increases surface area by 35% while maintaining structural integrity, creating superior heat dissipation capabilities.

Performance Comparison: With vs. Without Embossed Heat Shield

Parameter

With Heat Shield

Without Heat Shield

Improvement

Surface Temp Reduction

220°C → 85°C (-61%)

Maintains 220°C+

61% cooler

Component Longevity

120,000+ miles

60,000-80,000 miles

+50% lifespan

Maintenance Intervals

25,000 mile cycles

15,000 mile cycles

67% longer

Cabin Heat Transfer

≤45°C at floorboard

65-80°C at floorboard

40% reduction

Corrosion Resistance

5X standard stainless

Standard degradation

500% improvement

Key Advantages

Active Cooling Architecture: Embossed patterns create turbulent airflow, accelerating heat dissipation by 28% compared to flat shields

Triple-Layer Protection: Patented 304SS core with oxidation-resistant coating withstands 950°C continuous exposure

Vibration Damping: Reduced harmonic resonance by 42% through stress-distributing emboss pattern

Weight Efficiency: 22% lighter than traditional double-wall shields with equivalent protection

Operational Impact

When implemented on diesel exhaust systems:

-

Turbocharger efficiency increases 8-12% through maintained optimal temps

-

Aftertreatment system durability improves 40% (DOC/DPF protection)

-

Underhood plastic/rubber components last 3X longer

-

Fuel efficiency gains of 2-4% from reduced heat-induced friction

Technical Validation

Third-party testing verifies:

-

0.38 emissivity rating (vs 0.85 for unshielded pipes)

-

92% radiant heat blockage efficiency

-

Meets ISO 17949:2020 thermal shielding standards

Upgrade your exhaust system with our aerospace-derived heat management solution - where advanced metallurgy meets precision engineering. Contact our thermal specialists to calculate your specific ROI potential.

Exhaust Heat Wrap is a crucial solution for vehicles that need enhanced thermal protection. It reduces heat loss from the exhaust system, improves performance by increasing exhaust gas velocity, and protects surrounding components from heat damage. The wrap is commonly used in motorsports, high-performance vehicles, and even street cars that need extra protection against heat.

Here are five types of vehicles where exhaust heat wrap can be used:

-

Sports Cars (e.g., Chevrolet Corvette): Heat wrap helps improve exhaust efficiency, enabling the engine to perform at its best during high-speed driving and intense performance.

-

Motorcycles (e.g., Yamaha YZF-R1): The exhaust system on motorcycles is exposed to high temperatures; wrapping helps prevent heat soak, protecting riders and components.

-

Off-Road Vehicles (e.g., Jeep Wrangler): For off-road enthusiasts, exhaust heat wrap shields vital components from extreme heat, ensuring they remain functional in harsh conditions.

-

Street Cars (e.g., Ford Mustang): Many street vehicles benefit from exhaust wraps to maintain consistent engine temperature and improve fuel efficiency.

-

Racing Cars (e.g., Formula 1 Cars): In motorsports, wrapping exhaust pipes increases performance by optimizing heat dissipation and protecting the engine's other sensitive components from overheating.

Different Materials of Exhaust Heat Wrap:

-

Fiberglass Wrap: One of the most common materials, it’s effective in retaining heat inside the exhaust system, improving the flow of gases and performance.

-

Titanium Wrap: Known for its extreme heat resistance, titanium wrap offers higher durability, especially under higher temperatures and conditions.

-

Carbon Fiber Wrap: A more lightweight option, carbon fiber is heat resistant and perfect for applications that demand both strength and lightness.

-

Aluminized Wrap: This wrap reflects heat instead of retaining it, offering a protective barrier for nearby components and enhancing exhaust flow.

Endless web slings are a cornerstone of modern lifting operations, valued for their flexibility, strength, and reliability. Often overlooked due to their simplistic appearance, these versatile tools play a pivotal role in numerous industries where effective and safe lifting techniques are paramount. However, defining these essential tools correctly can sometimes be a challenge. Let's delve deeper into the world of lifting equipment and uncover the alternate names by which endless web slings are known in various industrial circles.

Endless web slings are frequently referred to as continuous loop slings due to their seamless, unbroken construction. This name aptly describes the design of these slings, whose circular nature allows for uniform weight distribution and enhanced load-bearing capabilities.

Another common moniker for endless web slings is round slings. Despite the flexible, flat nature of webbing material, these slings achieve a circular shape when loaded, providing a secure grip around the lifted item. The round sling designation emphasizes the all-encompassing support these slings offer, making them an indispensable tool for a diverse range of lifting applications.

Some professionals in the lifting and rigging sector may also use the term belt slings to describe endless web slings. This designation underscores the similarity between these slings and traditional belts, highlighting their role in securing and supporting heavy loads with efficiency and ease.

In certain industries, endless web slings are affectionately referred to as soft rounds. This term reflects their pliable nature and the gentle touch they provide to delicate or sensitive loads during lifting operations. The soft round designation underscores the versatility of these slings in accommodating various shapes and sizes without causing damage.

Endless web slings, known by these alternate names, are an indispensable asset in the realm of lifting and rigging. Their ability to conform to diverse load shapes, distribute weight evenly, and withstand heavy loads makes them a go-to solution for ensuring safe and efficient lifting operations across industries. Understanding the various names associated with endless web slings sheds light on the multiple dimensions of their utility and underscores their significance in contemporary lifting practices.

Regardless of the name used to describe them, the enduring value of endless web slings lies in their reliability, adaptability, and capacity to enhance the safety and efficacy of lifting tasks in industrial settings.

Ratchet straps are essential tools for securing cargo during transportation, ensuring that items remain stable and safe while being moved. But have you ever wondered why they are referred to as "ratchet straps"? The name itself provides a clue to one of the key components that sets these straps apart and makes them so effective in their purpose.

The term "ratchet" in "ratchet straps" refers to the mechanism incorporated into these straps that allows for incremental and controlled tightening of the strap. This ratcheting mechanism consists of a gear and a pawl that work together to prevent the strap from loosening once tension is applied. This design enables users to tighten the strap securely around the cargo with ease and precision, providing a level of control that other types of cargo straps may lack.

The ratcheting mechanism works by allowing the user to pull the loose end of the strap through the ratchet and then crank the handle back and forth. With each back-and-forth motion, the gear inside the ratchet tightens the strap incrementally until the desired level of tension is achieved. The pawl, a small metal piece with teeth, holds the strap securely in place, preventing it from unwinding and maintaining the tension throughout the journey.

This design feature of ratchet straps offers several advantages over traditional straps with simple buckles or cam buckles. The ratcheting mechanism allows for greater control over the tension applied to the strap, ensuring a tighter and more secure hold on the cargo. This precise adjustment capability is particularly useful when securing heavy or irregularly shaped loads that require extra stability during transportation.

The name "ratchet straps" underscores the innovative and efficient design of these cargo securing tools. By combining strength, durability, and the precise tightening action facilitated by the ratcheting mechanism, ratchet straps have become a preferred choice for professionals in various industries, including logistics, transportation, construction, and moving services.

The term "ratchet straps" reflects the unique functionality and efficacy of these cargo securing devices. The ratcheting mechanism plays a pivotal role in providing users with the control and security needed to ensure that their cargo remains safe and stable during transit. With their ease of use, reliability, and precision tightening capabilities, ratchet straps continue to be a go-to solution for professionals seeking a dependable and efficient method of securing loads for transportation.

When it comes to securing cargo during transportation, ensuring that loads are properly lashed down is crucial for both safety and regulatory compliance. Ratchet straps, with their efficient tightening mechanisms and reliable performance, are commonly used for this purpose. One key consideration when using ratchet straps is understanding their lashing capacity and how it impacts their safe usage.

The lashing capacity of a ratchet strap refers to the maximum load weight that the strap can safely secure in a particular application. This capacity is determined by various factors, including the material strength of the strap, the design of the ratchet mechanism, and the quality of the overall construction. It is essential to adhere to the specified lashing capacity to prevent overloading, which can lead to strap failure and pose serious safety risks.

Manufacturers typically provide the lashing capacity of ratchet straps in terms of both Working Load Limit (WLL) and Minimum Breaking Strength (MBS). The Working Load Limit indicates the maximum load that the strap can safely handle during normal use, while the Minimum Breaking Strength represents the point at which the strap will fail. It is important to note that the Working Load Limit is a fraction of the Minimum Breaking Strength, as a safety factor is built in to ensure reliable performance under varying conditions.

To determine the appropriate ratchet strap with the right lashing capacity for a specific application, it is essential to consider factors such as the weight and size of the load, the mode of transportation, and any regulatory requirements. Selecting a ratchet strap with a lashing capacity that exceeds the anticipated load weight helps to ensure a secure and safe transport operation.

In conclusion, understanding the lashing capacity of ratchet straps is critical for maintaining cargo security and transport safety. By adhering to the specified Working Load Limit and considering key factors in selecting the right strap for the job, operators can effectively secure their loads and mitigate the risks associated with improper strapping. Prioritizing safety and compliance through proper usage of ratchet straps contributes to efficient and successful cargo transportation.

When it comes to lifting and handling heavy loads, slings play a crucial role in ensuring safety and efficiency. There are various types of slings available, each designed for specific lifting applications. Understanding the different types of slings and their characteristics is essential for selecting the right equipment for the job. In this blog post, we will explore the three basic types of slings commonly used in lifting operations.

Wire rope slings are among the most durable and versatile lifting slings available. They are constructed from high-strength steel wire ropes that provide excellent tensile strength and resistance to abrasion. Wire rope slings are suitable for heavy-duty lifting tasks in rugged environments such as construction sites, shipyards, and industrial facilities. These slings come in various configurations, including single-leg, two-leg, three-leg, and four-leg designs, offering flexibility for different lifting applications.

Chain slings are another popular choice for heavy lifting operations. These slings are made up of alloy steel chain links that are incredibly strong and resistant to wear and tear. Chain slings are well-suited for applications where a high level of strength and durability is required, such as in steel mills, foundries, and machine shops. They are available in various configurations, including single-leg, double-leg, and multi-leg designs, offering different lifting capacities and configurations based on the load requirements.

Webbing slings, or synthetic slings, are made from woven synthetic materials such as polyester, nylon, or polypropylene. These slings are lightweight, flexible, and offer excellent load-bearing capacity while being gentle on the load surface. Webbing slings are commonly used in applications where non-metallic slings are preferred to avoid damage to delicate surfaces or where a lightweight lifting solution is needed. They are ideal for industries such as manufacturing, warehousing, and logistics, where lifting lighter loads and protecting the load surface are essential.

Each type of sling has its advantages and is suitable for specific lifting applications. Understanding the characteristics and capabilities of wire rope slings, chain slings, and webbing slings is crucial for ensuring safe and efficient lifting operations. By selecting the right type of sling based on the load requirements, environmental conditions, and safety considerations, operators can enhance workplace safety, protect the load being lifted, and improve overall lifting efficiency.

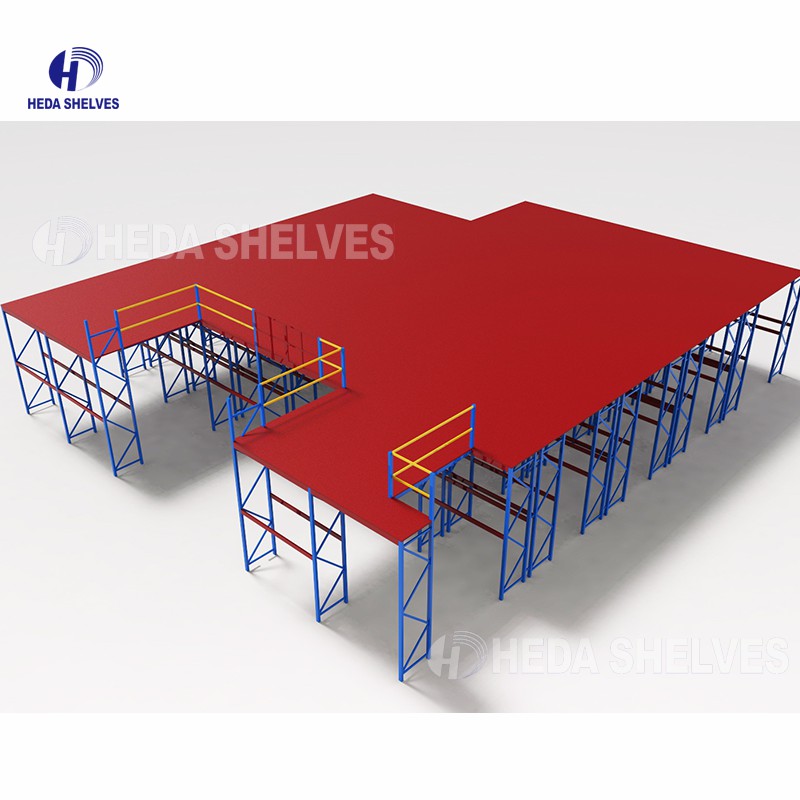

Choosing the right storage racking for your warehouse or other storage equipment can be daunting. When You pack your pallets or bulk storage goods, how to choose the right racking system.

This scenario can turn a fun outing into a stressful experience. Understanding the differences between multi-tier shelving and pallet racking system can help you avoid such pitfalls. Let’s dive deeper into each type and find the best fit for your needs.

What is an Multi-tier shelving system?

A multi-tier shelving system is a manual storage solution designed to maximize vertical warehouse space by creating multiple levels or tiers of shelving within the same footprint. It consists of shelving units arranged on different floors connected by staircases or lifts, allowing direct access to all stored items on each level.

This system is ideal for storing small to medium-sized goods, cartons, or SKUs that require manual picking without the need for forklifts on upper levels. Multi-tier shelving can be standalone or integrated with conveyors and other automation to improve picking throughput and storage capacity without expanding the warehouse floor area

Multi-tier shelving system Pros and Cons

Pros:

Maximizes vertical space: potentially doubling or tripling storage capacity without increasing warehouse footprint.

Easy to Access By Manual: Improving picking efficiency and reducing travel time.

Cost-effective: low cost than set up more layer construction structure.

Cons:

Storage Weight Limited: Suit for Light weight Inventory not heavy duty.

Manual Picking Limited :Requires stair access and potentially lifts, which may slow down movement compared to forklift access for heavy pallets

Higher investment: Installation complexity and initial investment can be higher than simple shelving.

What is an pallet racking system?

A pallet racking system is a material handling storage aid designed to store palletized goods on racks that are accessed primarily by forklifts. It consists of upright frames and horizontal beams that hold pallets at various levels, allowing efficient use of floor and vertical space.

Pallet racking systems provide direct or compacted access to pallets and are widely used in warehouses for bulk storage of large, heavy items on pallets. Different types include selective pallet racking (direct access), drive-in/drive-through racking, push-back racking, and pallet flow racking, each with specific inventory management methods like FIFO or LIFO.

Pallet Racking System Pros and Cons

Pros

Direct access to each pallet, facilitating easy stock management and picking.

Efficient use of vertical space for bulk storage of heavy goods on pallets.

Flexible and scalable to accommodate various pallet sizes and warehouse configurations.

Durable and robust, made from industrial-strength steel.

Can increase storage density depending on the type of racking used (e.g., pallet flow or push-back racking

Cons

Requires forklifts and wide aisles for maneuvering, increasing space needed for aisles and operational costs.

Higher upfront cost compared to shelving systems due to structural components and equipment needs.

Less suitable for small or irregularly sized items that require manual picking.

Some types have reduced flexibility and are best suited for uniform pallet sizes and slower inventory turnover

| Feature | Multi-tier Shelving | Pallet Racking |

| Storage Method | Shelves arranged in multiple vertical tiers | Pallets stored on racks accessed by forklifts |

| Best For | Small to medium-sized goods, manual picking | Bulk storage of palletized goods |

| Access | Direct manual access on all levels via stairs | Forklift access in aisles, direct or compacted |

| Space Utilization | Maximizes vertical space, doubles/triples capacity | Uses vertical space but requires aisle width for forklifts |

| Flexibility | Highly flexible and modular for various goods | Flexible but best with uniform pallets |

| Cost | Moderate initial cost, cost-effective for height use | Higher upfront cost, especially for complex systems |

| Equipment Needed | Minimal (manual picking) | Forklifts and handling equipment required |

| Safety | Safer for workers due to less forklift use | Requires forklift operation, risk of impacts |

Pallet Racking Vs. Multi-tier Shelving: which is better?

The decision comes down to your specific needs:

Choose Pallet Racking System if you want a budget-friendly option for pallet storage. If your warehouse use for auto parts, logistic, cold storage and product more than 1000KG , this could be your go-to racking.

Choose Multi-tier Shelving if you’re manage the inventory without forklift. Whether you’re store cartons or other small item in manual or high turnover order picking, the reliability and maintenance-free storage shelving system can enhance your experience.

Can I Use Both the racking and shelving?

Yes, many warehouses combine both systems to optimize storage:

- Use pallet racking for bulk storage of heavy palletized goods.

- Use multi-tier shelving for smaller items, order picking, or overflow storage.

- Combining systems maximizes space utilization, improves picking efficiency, and adapts to diverse inventory types

Conclusion

Multi-tier shelving and pallet racking systems serve different but complementary storage needs. Multi-tier shelving excels at maximizing vertical space for manual picking of small to medium items, offering flexibility and cost efficiency. Pallet racking is best for bulk storage of heavy palletized goods requiring forklift access.

Selecting the right system depends on your inventory type, warehouse layout, budget, and operational priorities. Often, integrating both systems provides the best overall warehouse storage solution, enhancing space utilization and workflow efficiency. If you need expert help, Contact Heda Shelves Now.

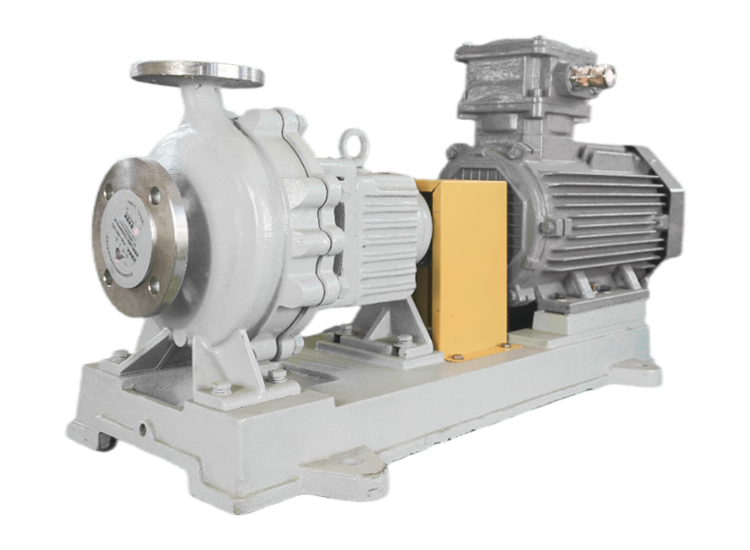

THJ Chemical Process Centrifugal Pump: Key Role in Evaporation Systems

I. Main Tasks of Pumps in Evaporation Systems

1. Material Transfer: The THJ centrifugal pump is crucial in evaporation and crystallization setups. It moves feedstock, intermediate products, condensate, and concentrated liquids between containers or pushes fluids through heaters and heat exchangers.

2. Circulation & Mixing: In some crystallization methods, the THJ pump keeps the solution circulating. This helps distribute heat evenly, stops hot spots, and ensures even crystal growth.

3. Flow & Pressure Control: By changing speed or valve settings, the THJ pump controls flow rates into evaporators and manages pressure in the system. This is key for consistent evaporation and crystallization.

4. Flow Rate & Head: It’s important to accurately figure out the flow and head needed for the system to avoid inefficient pump operation, which saves energy.

5. Corrosion Resistance & Materials: Since these pumps face acids, bases, and salts, they need to be made from tough materials like stainless steel, titanium, alloy steel, or have protective coatings.

6. Temperature & Pressure Tolerance: Pumps should handle high temperatures and pressures for reliable performance during intense crystallization.

7. Wear Resistance: With solid particles present, pumps need durable designs, like open impellers or special liners, to reduce wear.

8. Self-Priming & Cavitation Resistance: For jobs with frequent starts and stops or cavitation risks, pumps should be able to self-prime easily.

9. Sealing Systems: Double-face cartridge mechanical seals are best for handling abrasive materials while ensuring durability and staying eco-friendly.

10. Maintenance & Cleanability: Pumps that deal with crystallizing fluids should be easy to take apart for maintenance and cleaning.

11. Energy Efficiency: High-efficiency THJ pumps that meet industry standards can lower operating costs and fit well with eco-friendly practices.

II. Choosing Evaporation-Crystallization Pumps

THJ centrifugal pumps work differently from standard designs by using impeller thrust instead of just centrifugal force to move fluids:

1. Fluid Intake: The motor turns, creating a vacuum that pulls liquid into the pump.

2. Energy Transfer: Helical impeller blades create thrust, adding kinetic and pressure energy to the fluid.

3. Discharge: The fluid speeds up as it exits the pump, and the vacuum keeps the process going. This approach is great for high-flow, low-head tasks.

III. Industrial Uses

THJ pumps are common in evaporation, crystallization, and chemical processes across various industries:

1. Phosphate Fertilizers: Used in phosphoric acid and ammonium phosphate production.

2. Bayer Process Alumina: Circulates aluminum sodium solutions in evaporators.

3. Chlor-Alkali: Handles evaporation of caustic soda with salt.

4. Vacuum Salt Production: Circulates liquid in salt crystallizers.

5. Sodium Sulfate Plants: Manages Na₂SO₄ evaporation tasks.

6. Hydrometallurgy: Used in copper and nickel sulfate crystallization.

7. Alkali Refining: Works with NH₄Cl crystallizers.

8. Soda Ash: Recovers CaCl₂ in evaporators.

9. Pulp & Paper: Concentrates black liquor.

10. Power Plants: Involved in Flue Gas Desulfurization systems and ammonium sulfate crystallizers.

11. Light Industry: Used in alcohol, citric acid, and sugar evaporation.

NdFeB magnets are key products from Zoyn Magnetics, and they are some of the strongest permanent magnets out there, used in many industries. When we talk about NdFeB magnets, two types come up: bonded and sintered. Each has its own traits and uses, so knowing the differences can help you decide what's best for you.

One of the main differences lies in the manufacturing process. Strong sintered NdFeB magnets are made using a powder metallurgy process. The neodymium, iron and boron alloys are first ground into a fine powder. The powder is then pressed under high pressure in a mould to achieve the desired shape. Afterwards, the pressed powder is sintered at high temperatures to fuse the particles together to form a dense and strong magnet. In contrast, bonded NdFeB magnets are made by mixing neodymium powder with a bonding material, such as plastic or rubber. The mixture is then moulded or extruded into the desired shape, resulting in a more homogeneous structure of the magnet due to the even distribution of the binder.

These manufacturing differences can lead to variations in physical properties. Neodymium N52 disc magnet typically have higher magnetic strength. They have higher remanence (the magnetic flux density remaining after the magnetising field is removed) and coercivity (resistance to demagnetisation), making them ideal for applications that require a strong, stable magnetic field, such as electric motors and MRI machines. On the other hand, bonded neodymium magnets have lower magnetic properties. However, they excel in areas such as dimensional accuracy and complex shape forming. Complex shapes and thin-walled parts can be manufactured using bonded materials, which are difficult to achieve with sintered magnets.

Durability and corrosion resistance also differentiate these two types of magnets. Sintered neodymium magnets are susceptible to corrosion due to their porous structure, which is easily penetrated by moisture and other contaminants. As a result, they usually require additional surface treatments such as nickel-copper-nickel plating for protection. Bonded neodymium magnets typically have better inherent corrosion resistance due to the presence of a binder material. The binder encapsulates the neodymium particles, creating a natural environmental barrier that in many cases reduces the need for complex surface protection.

Cost is another important factor. Customized shaped Ndfeb magnets typically involve more complex manufacturing processes and often require additional post-treatment steps for surface preparation, which can drive up costs. Bonded neodymium magnets, which are simpler to manufacture and do not require extensive surface treatment, are often more cost-effective, especially in applications where magnetic strength is not a primary concern.

Both bonded and sintered NdFeB magnets from Zoyn Magnetics have their pros and cons. By understanding their differences, like how they're made, their physical properties, durability, and price, you can pick the right option for your needs, whether in electronics, automotive, or other fields. If you want more info about our products, just ask!

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2