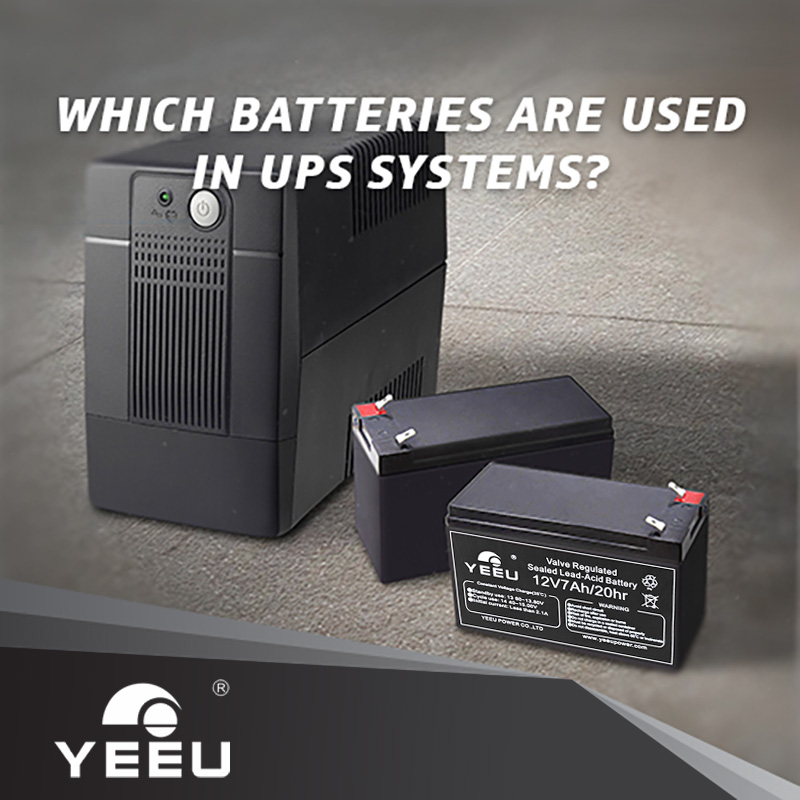

In recent years, the sudden rise of lithium batteries has had a strong impact on the lead-acid battery industry. However, there are still some industries that insist on using lead-acid batteries like ups systems Why? This blog will take you to understand why people in UPS industry still choose lead-acid batteries when lithium batteries taking up many more of the markets.

UPS systems still stick to using lead-acid batteries for several reasons:

Cost-effectiveness

Cost-effectiveness

Lead-acid batteries are relatively inexpensive compared to newer technologies like lithium-ion. They offer a favorable cost-to-energy ratio over their lifespan, making them an economical choice for large-scale applications.

Proven Reliability

Proven Reliability

Lead-acid batteries have a long history of use in power backup applications, with a proven track record of reliability. They can provide consistent, stable power, which is crucial for UPS systems.

High Energy Output

High Energy Output

These batteries are capable of delivering high currents for short periods, making them ideal for UPS systems that need to provide power immediately when an outage occurs.

Widespread Availability

Widespread Availability

Lead-acid batteries are readily available and have a well-established supply chain. This makes them easy to source and replace, minimizing downtime in case of battery failure.

Low Self-discharge Rate

Low Self-discharge Rate

Lead-acid batteries have a low self-discharge rate, meaning they can retain their charge for longer periods when not in use. This is important for UPS systems, where the battery may only be used occasionally but needs to be ready at a moment’s notice.

Scalability

Scalability

Lead-acid batteries are highly scalable, allowing UPS systems to be customized according to the needs of the application. They can be configured to meet varying power requirements, making them a flexible solution for diverse applications.

Temperature Tolerance

Temperature Tolerance

Lead-acid batteries have a wide operating temperature range, making them suitable for use in various environments, including those with extreme temperatures.

Maintenance-free Options

Maintenance-free Options

Valve-regulated lead-acid (VRLA) batteries, which are the most common type used in modern UPS systems, are sealed and require minimal maintenance.

While lithium-ion battery technologies continue to advance and offer certain advantages such as higher energy density and lighter weight, lead-acid batteries remain a reliable and cost-effective choice for UPS systems, particularly for applications that prioritize long-term reliability and cost-efficiency.

Lifting slings are essential tools in material handling, construction, logistics, and industrial applications. Whether you're lifting heavy machinery, securing cargo, or managing loads in a warehouse, choosing the right lifting sling can significantly impact safety, efficiency, and durability. This guide introduces the fundamental aspects of lifting slings, including their types, materials, specifications, and common applications.

1. Types of Lifting Slings

Lifting slings come in various designs, each suited for different lifting needs. The most common types include:

a. Webbing Slings

Webbing slings are made from polyester or nylon fabric, offering flexibility and lightweight handling. These slings are ideal for lifting delicate or finished surfaces since they do not damage the load.

-

Pros: Soft, lightweight, flexible, and corrosion-resistant.

-

Cons: Less durable against sharp edges and high temperatures.

-

Common Uses: Lifting machinery, construction materials, and cargo handling.

b. Round Slings

Round slings consist of multiple strands of polyester or nylon yarn enclosed in a protective fabric sleeve. These slings distribute weight evenly and provide a secure grip on loads.

-

Pros: High strength, lightweight, and flexible.

-

Cons: Susceptible to cuts if not protected properly.

-

Common Uses: Heavy machinery lifting, marine applications, and industrial settings.

c. Chain Slings

Chain slings are made from high-strength alloy steel chains, offering maximum durability and resistance to harsh environments. These slings are best for lifting extremely heavy loads.

-

Pros: Heat-resistant, durable, and suitable for rugged use.

-

Cons: Heavy and prone to corrosion if not properly maintained.

-

Common Uses: Foundries, shipyards, and construction sites.

d. Wire Rope Slings

Wire rope slings are made from strands of steel wire twisted into a robust rope, providing excellent strength and durability. These slings are widely used in industrial and marine applications.

-

Pros: High tensile strength and resistant to abrasion.

-

Cons: Less flexible than webbing or round slings.

-

Common Uses: Heavy lifting in construction, offshore industries, and cranes.

e. Metal Mesh Slings

Metal mesh slings are constructed from interwoven steel wires, offering superior durability for lifting abrasive or hot materials.

-

Pros: Heat-resistant and strong.

-

Cons: Heavier and less flexible.

-

Common Uses: Foundries and metalworking industries.

2. Materials of Lifting Slings

Lifting slings are manufactured using different materials to cater to specific lifting requirements. The primary materials include:

-

Polyester: Lightweight, UV-resistant, and low stretch. Suitable for delicate loads and outdoor applications.

-

Nylon: Higher elasticity than polyester, offering shock absorption. Ideal for dynamic lifting applications.

-

Steel (Alloy and Wire Rope): Provides high durability and strength, best for heavy-duty applications.

3. Lifting Sling Specifications

When selecting a lifting sling, understanding key specifications ensures safe and effective operations:

a. Load Capacity (Working Load Limit - WLL)

Each sling has a rated working load limit, which varies based on material and sling type. Exceeding this limit can lead to failures and accidents.

b. Sling Length and Width

The length and width of a sling determine its lifting capacity and the type of load it can handle. Wider slings provide better weight distribution.

c. Safety Factor

Slings are designed with a safety factor (typically 5:1 or 7:1 for synthetic slings and 4:1 for steel slings), ensuring they can handle multiple times their rated capacity under ideal conditions.

d. End Fittings and Attachments

Different slings feature various end fittings such as hooks, shackles, or loops to enhance versatility and safety.

4. Common Applications of Lifting Slings

Lifting slings are used in various industries depending on their properties:

-

Construction: Lifting beams, pipes, and concrete structures.

-

Manufacturing: Moving heavy machinery and industrial components.

-

Logistics & Warehousing: Cargo securing and transportation.

-

Maritime & Offshore: Shipbuilding and offshore rigging.

-

Automotive & Aerospace: Handling large vehicle components and aircraft parts.

5. Best Practices for Safe Use of Lifting Slings

To ensure the longevity of lifting slings and workplace safety, follow these best practices:

-

Inspect Before Use: Check for signs of wear, cuts, abrasions, and deformations.

-

Use Proper Protection: Use corner protectors or sleeves to prevent damage to the sling and load.

-

Follow Load Limits: Never exceed the rated capacity of the sling.

-

Store Properly: Keep slings in a dry, cool place, away from chemicals and direct sunlight.

-

Train Personnel: Ensure workers are educated on proper handling and safety guidelines.

Understanding the basics of lifting slings—types, materials, specifications, and applications—can help you make informed choices for your lifting needs. Whether using webbing slings for delicate loads or chain slings for extreme lifting conditions, selecting the right equipment is essential for efficiency and safety. By adhering to best practices and maintenance guidelines, you can enhance the durability and performance of lifting slings in your operations.

When it comes to lifting heavy loads safely and efficiently, choosing the right lifting equipment is crucial. Among the many lifting tools available, webbing slings Webbing slings are flexible lifting devices made from high-strength synthetic fibers such as polyester Webbing slings are known for their exceptional strength-to-weight ratio Whether lifting from the center of gravity or at multiple points, webbing slings can handle various lifting configurations. Their flexibility allows them to adjust to uneven loads or awkward lifting angles, making them highly adaptable for different applications. Webbing slings made from polyester Unlike metal slings, webbing slings require minimal maintenance. They are easily cleaned and inspected, which simplifies the process of ensuring they remain in good working condition. Many slings also come with color-coded tags Webbing slings are the perfect balance of strength, versatility, and safety. Their flexibility, combined with their lightweight design, makes them ideal for lifting in confined spaces or for handling delicate loads. Whether you’re lifting construction materials, machinery, or cargo, webbing slings provide the reliability and safety that you need. At NANJING D.L.T SLING CO.,LTD

A duplex webbing sling is a high-strength, flexible lifting sling made from two layers of durable synthetic webbing, commonly used for heavy lifting and secure load handling. These slings are widely preferred in industries such as construction, logistics, and manufacturing due to their lightweight, strong load-bearing capacity, and excellent safety features.

High Strength & Durability

Duplex webbing slings are made from high-quality polyester ,offering excellent load distribution and resistance to wear, UV exposure, and moisture.

Flexible & Lightweight

Unlike chain slings or wire ropes, webbing slings are softer and more flexible, reducing damage to delicate loads while being easier to handle and store.

Increased Safety

With a high safety factor (typically 7:1), duplex webbing slings provide a secure and reliable lifting solution, minimizing the risk of load slippage or failure.

Customizable & Versatile

Available in various lengths, widths, and capacities, these slings can be color-coded for easy identification, ensuring efficient operations on-site.

Where Are Duplex Webbing Slings Used?

· Construction & Infrastructure – Lifting steel beams, precast concrete, and heavy machinery.

· Shipping & Logistics – Securing and lifting cargo safely.

· Manufacturing & Engineering – Handling components with precision and care.

· Automotive & Aerospace – Moving delicate parts without surface damage.

Find the Best Duplex Webbing Sling for Your Needs

At NANJING D.L.T SLING, LTD, we manufacture high-quality duplex webbing slings that meet international safety standards. Our slings are CE and GS certified, ensuring reliability in demanding industrial environments. Contact us today to get expert advice on selecting the right lifting sling for your business!

📩 Get in touch with us today for a free consultation!

The ASME (American Society of Mechanical Engineers) standard for webbing slings, specifically ASME B30.9, governs the safe use, maintenance, and inspection of webbing slings, which are used for lifting operations in various industries. This standard provides guidelines to ensure that webbing slings are used safely and effectively, preventing accidents and ensuring the safety of operators and the integrity of loads being lifted.

Webbing slings must be made of materials that are durable and resistant to wear and tear. Common materials used include nylon, polyester, and polypropylene. The ASME standard requires that slings made of synthetic materials be resistant to environmental factors like UV light, abrasion, and chemicals to ensure their longevity and safety.

The ASME standard dictates the minimum size, length, and strength of webbing slings to ensure they can handle the required loads. It also specifies how slings should be designed to minimize damage during use, such as avoiding sharp edges and ensuring the slings have adequate load capacity. The sling's capacity is often indicated on a label that includes the working load limit (WLL).

Regular inspection and maintenance are critical to the safe use of webbing slings. The ASME B30.9 standard provides detailed guidance on the inspection process. It requires operators to examine slings for signs of wear, fraying, and other types of damage before use. Slings should also be cleaned after each use to maintain their integrity.

ASME B30.9 outlines the importance of using the proper lifting techniques to prevent accidents. This includes ensuring the load is balanced and that the sling is correctly positioned. Operators must also be trained on how to safely use webbing slings to ensure the load is secured properly and the sling is not overloaded.

Webbing slings must undergo rigorous testing to ensure they meet the required safety standards. The ASME standard mandates load testing procedures to verify that slings can safely handle the specified weight limits. All webbing slings should be certified, and the certification labels should be visible and legible.

Webbing slings have a limited lifespan, depending on their usage and the conditions they are exposed to. The ASME B30.9 standard requires that slings be retired after a certain number of uses or when they show signs of damage. Proper disposal procedures are also part of the standard to prevent accidents due to the use of damaged slings.

People in lead-acid battery industry all had a slow start after coming back from Chinese New Year. It was so out of a norm and they may wonder why the competition of lead-acid battery has become more fierce? This blog will tell you several key factors that made this tricky situation.

1. High Market Potential and Growth Opportunities

Increasing Demand: The lead-acid battery market is driven by strong demand from key industries such as automotive (for SLI applications), uninterruptible power supply (UPS), and off-grid power solutions. The global market is projected to reach a valuation of US$ 91.76 billion by 2033, creating significant opportunities for companies to capture market share.

Increasing Demand: The lead-acid battery market is driven by strong demand from key industries such as automotive (for SLI applications), uninterruptible power supply (UPS), and off-grid power solutions. The global market is projected to reach a valuation of US$ 91.76 billion by 2033, creating significant opportunities for companies to capture market share.

Emerging Applications: New applications such as renewable energy storage (e.g., solar power systems) and data centers are opening up additional growth avenues. Companies are eager to tap into these emerging markets, leading to increased competition.

Emerging Applications: New applications such as renewable energy storage (e.g., solar power systems) and data centers are opening up additional growth avenues. Companies are eager to tap into these emerging markets, leading to increased competition.

2. Technological Advancements and Innovation

Performance Improvements: Advances in lead-acid battery technology, such as improved electrode materials, advanced grid designs, and better electrolyte formulations, have enhanced the performance, lifespan, and efficiency of lead-acid batteries. Companies are constantly investing in R&D to stay ahead of competitors.

Performance Improvements: Advances in lead-acid battery technology, such as improved electrode materials, advanced grid designs, and better electrolyte formulations, have enhanced the performance, lifespan, and efficiency of lead-acid batteries. Companies are constantly investing in R&D to stay ahead of competitors.

Hybrid Technologies: Some manufacturers are developing hybrid lead-acid batteries that combine the benefits of traditional lead-acid batteries with newer technologies (e.g., incorporating supercapacitors) to improve performance and meet evolving customer needs.

Hybrid Technologies: Some manufacturers are developing hybrid lead-acid batteries that combine the benefits of traditional lead-acid batteries with newer technologies (e.g., incorporating supercapacitors) to improve performance and meet evolving customer needs.

3. Cost and Sustainability Factors

Cost-effectiveness: Lead-acid batteries are significantly cheaper than lithium-ion and other advanced batteries. This cost advantage makes them attractive for applications where budget constraints are a consideration, such as in the automotive and UPS markets.

Cost-effectiveness: Lead-acid batteries are significantly cheaper than lithium-ion and other advanced batteries. This cost advantage makes them attractive for applications where budget constraints are a consideration, such as in the automotive and UPS markets.

Recycling Infrastructure: Lead-acid batteries have a well-established recycling infrastructure, with over 90% of them being recycled globally. This sustainability advantage is a key selling point, especially as environmental regulations become stricter. Companies are leveraging this to appeal to environmentally conscious customers and regulators.

Recycling Infrastructure: Lead-acid batteries have a well-established recycling infrastructure, with over 90% of them being recycled globally. This sustainability advantage is a key selling point, especially as environmental regulations become stricter. Companies are leveraging this to appeal to environmentally conscious customers and regulators.

4. Regulatory and Environmental Pressures

Stringent Regulations: Governments around the world are imposing stricter regulations on battery manufacturing and disposal. While this presents challenges, it also creates opportunities for companies that can comply with these regulations and offer environmentally friendly solutions.

Stringent Regulations: Governments around the world are imposing stricter regulations on battery manufacturing and disposal. While this presents challenges, it also creates opportunities for companies that can comply with these regulations and offer environmentally friendly solutions.

Pressure to Innovate: Companies are under pressure to innovate and improve their products to meet regulatory standards and customer expectations. This has led to increased competition as firms strive to develop more sustainable and efficient lead-acid batteries.

Pressure to Innovate: Companies are under pressure to innovate and improve their products to meet regulatory standards and customer expectations. This has led to increased competition as firms strive to develop more sustainable and efficient lead-acid batteries.

5. Market Consolidation and New Entrants

Established Players: The market is dominated by a few large players who have significant market share and resources. However, these companies are constantly looking to expand their market presence through mergers and acquisitions.

Established Players: The market is dominated by a few large players who have significant market share and resources. However, these companies are constantly looking to expand their market presence through mergers and acquisitions.

New Entrants: The potential for high returns has attracted new entrants, both from within the industry and from adjacent sectors. These new players bring fresh ideas and technologies, further intensifying competition.

New Entrants: The potential for high returns has attracted new entrants, both from within the industry and from adjacent sectors. These new players bring fresh ideas and technologies, further intensifying competition.

6. Customer Expectations and Differentiation

Performance and Reliability: Customers are increasingly demanding higher performance, longer lifespans, and more reliable batteries. Companies are competing to meet these expectations by offering differentiated products with unique features.

Performance and Reliability: Customers are increasingly demanding higher performance, longer lifespans, and more reliable batteries. Companies are competing to meet these expectations by offering differentiated products with unique features.

After-sales Support: In addition to product quality, companies are also competing on the basis of after-sales support, warranties, and customer service. This has become a key differentiator in a highly competitive market.

After-sales Support: In addition to product quality, companies are also competing on the basis of after-sales support, warranties, and customer service. This has become a key differentiator in a highly competitive market.

7. Geographical Expansion

Global Reach: Many lead-acid battery manufacturers are expanding their operations globally to tap into emerging markets in Asia, Africa, and Latin America. This has led to increased competition in these regions as companies vie for local market share.

Global Reach: Many lead-acid battery manufacturers are expanding their operations globally to tap into emerging markets in Asia, Africa, and Latin America. This has led to increased competition in these regions as companies vie for local market share.

Regional Differences: Different regions have varying regulatory requirements, customer preferences, and market dynamics. Companies need to tailor their strategies to each region, adding another layer of complexity and competition.

Regional Differences: Different regions have varying regulatory requirements, customer preferences, and market dynamics. Companies need to tailor their strategies to each region, adding another layer of complexity and competition.

In conclusion, the combination of high market potential, technological advancements, cost and sustainability advantages, regulatory pressures, market consolidation, customer expectations, and global expansion has created a highly competitive environment in the lead-acid battery market.

Partnership

Anhui Shengshi Datang Chemical Equipment Group Co., Ltd. has established long-term partnerships with multiple listed companies, consistently providing technical support to ensure the smooth operation of their production lines. Recently, our technical team overcame significant challenges and successfully secured a cooperation agreement with a major chemical enterprise in Xi'an, Shanxi Province.

Selection

Centrifugal Pumps

As critical equipment for material transportation in chemical production, centrifugal pumps rely on centrifugal force to transfer fluids.

Before startup, it is essential to ensure that the pump body and feed pipe are fully filled with liquid to create a vacuum state. Once activated, the motor drives the impeller to rotate at high speed, causing the liquid to spin rapidly. Under the influence of centrifugal force, the liquid is propelled from the center of the impeller to its outer edge, gaining energy and exiting the impeller at high speed into the volute casing. Inside the volute, as the flow channel gradually expands, the liquid's velocity decreases, converting part of its kinetic energy into static pressure energy. The liquid then exits through the discharge pipe at higher pressure.

During this process, the center of the impeller forms a vacuum as the liquid is expelled, drawing more liquid from the storage tank into the feed pipe under atmospheric pressure or liquid level difference. This enables continuous transportation, akin to water droplets being flung outward when spinning an umbrella rapidly in the rain.

Installation

Proper installation is the foundation for the stable operation of chemical pumps. Our technical team formed a specialized group and traveled to the Xi'an facility to oversee the installation process.

Before installation, a comprehensive inspection of the pump and motor is required to ensure all components are intact, with no looseness or deformation. During installation, it is crucial to maintain the pump's levelness and alignment, as these directly impact its operational stability and service life. Using tools such as spirit levels, the pump's base is adjusted to keep vertical and horizontal deviations within specified limits.

Additionally, the alignment between the pump and motor must be ensured by adjusting the coupling's gap and position to align the centerlines of the two shafts, minimizing vibration and noise caused by misalignment. During installation, attention must also be paid to pipeline connections to prevent leaks and avoid imposing additional stress on the pump body. After installation, a trial run is conducted to check the pump's performance and promptly address any issues.

Function: Wall - type heat exchange between two media. There are various structural forms, such as: shell - and - tube graphite heat exchanger, round - block - hole graphite heat exchanger; rectangular - block - hole graphite heat exchanger, etc.

Graphite falling - film absorber

Function: Mass and heat transfer. Carry out falling - film absorption on soluble gases and remove the absorption heat at the same time. For example: shell - and - tube graphite falling - film absorber; round - block - hole absorber.

Combustion synthesis device

Function: Combustion or synthesis of combustible substances. It can also complete synthesis, cooling and absorption in one device at the same time; for example: water - jacketed hydrogen chloride synthesis furnace, three - in - one hydrochloric acid synthesis furnace, etc.

Graphite sulfuric acid dilution cooler

Function: Dilute (cool) sulfuric acid and other media, and can remove the dilution heat (cooling) in one device at the same time.

Graphite tower - type equipment

Function: Mass - transfer equipment for gas - liquid phase or liquid - liquid phase. Including plate towers and packed towers, etc.

Graphite mechanical equipment

Function: Equipped with a power device, used for mixing, reacting, concentrating, evaporating, etc. of materials.

Graphite - lined equipment

Function: Equipment with graphite rotors or plates as anti - corrosion linings.

Graphite pipelines and pipe fittings

Function: Used for transporting media and connecting equipment.

Graphite sealing materials

Function: Used for end - face sealing, packing sealing, flange sealing.

Graphite protective anode in cathodic protection system

Function: Used as an external - current protective anode in the cathodic protection system.

Fluoroplastic magnetic pumps replace dynamic seals with static seals, keeping the flow components completely sealed. This solves the problems of leakage, spouting and dripping that cannot be avoided by mechanical seals in other pumps. The magnetic pump selects engineering plastics, corundum ceramics and stainless steel with corrosion resistance and high strength as manufacturing materials. Therefore, it has good corrosion resistance and can prevent the conveyed medium from being contaminated. The magnetic pump has a compact structure, beautiful appearance, small size, low noise, reliable operation and convenient maintenance.

If no protective measures are taken for the flange of the fluoroplastic magnetic pump and it is exposed to a corrosive environment or contaminated industrial atmosphere, the corrosion rate will be very fast. In addition, due to the complex geometric shape of the flange connection, gap corrosion between the two flange faces and galvanic corrosion between different metals are prone to occur, which will seriously damage the integrity of the pipeline system. So how can flange connections prevent corrosion?

- Mechanical solutions: mainly by using protective covers and clamps to seal the gaps between flanges and flange faces, usually made of stainless steel or plastic with rubber sealing strips. This protection method is less flexible and requires storage of covers or clamps that match the size of various flanges completely.

- Thermoplastic solutions: Thermoplastics are essentially a kind of waxy fusible polymer heated at high temperature, which is sprayed onto the surface of the base material through professional thermoplastic equipment. The advantage of this protection method is that it can be remelted and reused, saving costs. However, this method still requires hot work, professional equipment and construction services. Although it can be reused, it is not easy to open and seal during maintenance.

- Tape or semi-solid anti-corrosion tape solutions: Rolled tapes (such as petrolatum tapes, wax or elastic polymer bandages) are protected by winding on the surface of the base material. Due to the good water resistance of semi-solid polymers, this protection method can provide reliable anti-corrosion protection.

- Maintenance paint solutions: Maintenance paint is a hard film that can be directly bonded to the base material, generally epoxy or polyurethane coatings. There are many corners and edges on the flange. Due to the edge thinning effect, conventional paint systems are difficult to effectively cover the edges. Although thickening the coating will solve the edge protection problem, it will also seal the fasteners and make them unable to be disassembled during subsequent maintenance. In addition, operating the bolt will damage the coating and must be repainted after maintenance.

- Polymer sealing bag solutions: The sealing bag can completely wrap the flange. Its composition consists of low-permeability polymers, corrosion inhibitor vapors and desiccants. It is easy to install, but the two ends of the bag are only sealed with tape instead of using a durable and effective mechanical bond. There is a large area of steam space inside the bag, which is easy to gather a lot of water, and the corrosion inhibitor will also be consumed over time.

The GH series floating-head tubular graphite heat exchanger, simply known as the floating-head tubular heat exchanger and also referred to as the graphite heat exchanger, is one of the products of Shengshi Datang, a graphite heat exchanger manufacturer with more than twenty years of production experience. Due to the special design of the equipment head and the use of graphite tubulars as the heat exchange medium for the internal tube sheets, it is named the GH series floating-head tubular graphite heat exchanger.

This article introduces three major design structures of the GH series floating-head tubular graphite heat exchanger of Shengshi Datang:

First, the design of this equipment takes into account the reduction of fluid resistance and is divided into two types: one is an ordinary heat exchanger, and the other is a condenser with a gas-liquid separator for an ordinary heat exchanger.

Second, this product is applied in technological transformation projects. The values are calculated based on the middle diameter of φ32/22 graphite tubes. For detailed design parameters (design pressure, design temperature, heat exchange area, etc.), please contact the technicians of Shengshi Datang, the graphite heat exchanger manufacturer.

Third, the floating-head tubular heat exchanger is widely used. This equipment is mainly used as a cooler, heater, condenser, and heater, etc. The following picture shows the structure diagram of the GH series floating-head tubular graphite heat exchanger of Shengshi Datang.

If you want to know more about where to find graphite heat exchangers, graphite condensers, graphite falling-film absorbers, graphite heaters and other graphite corrosion-resistant equipment, feel free to follow Anhui Shengshi Datang Chemical Equipment Group Co,Ltd.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2