Hydraulic seals, also called hydraulic cylinder seals or shaft seals, are parts used to keep fluids from escaping from cylinders, at the same time preventing contaminants from entering into cylinders.

They are critical parts in many types of machinery since they help create a method for fluid power to be converted into linear motion. These seals need to be designed and produced to withstand high pressure, or even high temperature in many of industries, in this case, the function of Hydraulic seals is not only preventing leakage of fluid from the Cylinder, it is also challenging for seals.

There’re combinations of seals, including hydraulic rod seals, hydraulic piston seals, wear rings or guide rings, scrapers or wipers. The functions of each are different.

The jst-seals rod seals prevent leakage of fluid from within the cylinder to the outside; Hydraulic Piston seals prevent fluid from flowing across the cylinder head; Wear rings guide the piston and piston rod within the hydraulic cylinder; Wipers scrape dirt or chips from the piston rods preventing contamination.

JST supply various types of hydraulic seals, and we’re able to do the tests related to temperature, pressure, tensile strength, reciprocating, etc. You’re welcome to reach our sales for price lists.

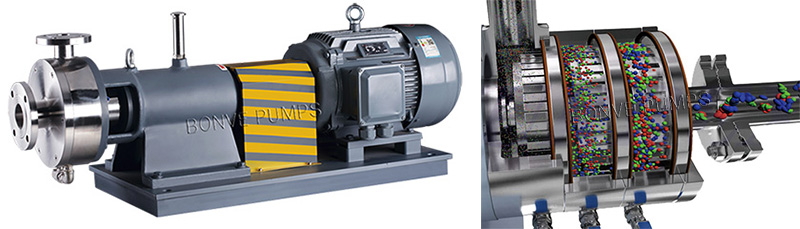

BONVE INLINE HIGH SHEAR EMULSIFYING AND HOMOGENIZING MIXER is a high-efficiency mixer integrating mixing, dispersing, crushing, dissolving, refining, depolymerizing, homogenizing and emulsifying. After homogenizer mixer, the original traditional production process is further simplified, the production efficiency is greatly improved, and the product quality is significantly improved too. Homogenization is an important step in creating the high-quality products that consumers expect. The benefits include improved product taste, texture and consistency, which then translate into increased sales and customer satisfaction.

Consistency of product ingredients

Homogeneous emulsification allows the ingredients to be uniformly dispersed in the medium, which is very important for the pharmaceutical industry, where active ingredients need to be uniformly dispersed in pills, tablets, capsules or syrups. In the cosmetic industry, customers expect their lotions and creams to have an even texture and appearance. In the food industry, customers want their products to taste more delicate and delicious.

Increase dissolution rate

The particle size of the product after EMULSIFYING AND HOMOGENIZING MIXER can reach 4-50 microns, which is especially important in the field of dissolution, because smaller and finer particles are easier to dissolve. In the pharmaceutical industry, this affects the bioavailability and efficacy of the drugs produced.

Higher stability of the final product

A successfully homogeneous emulsified product contains particles so small and fine that they do not fall out of solution. This is very important for the food and beverage industry - the last thing a customer wants is a bottle of juice with particles visibly falling out of solution!

Reduce costs

EMULSIFYING AND HOMOGENIZING MIXER not only improves product safety, but also reduces overall costs. Effective homogeneous emulsification generally reduces the need for processing chemicals and heat treatments, and can also reduce the potential cost of product recalls.

Bonve Lobe pumps: Empowering Paris 2024, demonstrating the power of technological innovation and sustainable development:

With the excitement of the Paris 2024 Olympic Games, all walks of life around the world are participating in this sports feast with unprecedented enthusiasm, and jointly promoting the deep integration of sportsmanship with scientific and technological innovation and green development. Behind this grand international gathering, Ningbo Bonve Pump Co., Ltd. with its excellent Positive Displacement Lobe pump technology, not only provides strong support for the Olympic-related industries, but also sets a new benchmark in the field of technological innovation and sustainable development, and perfectly interprets the "faster, higher, stronger - more united" Olympic spirit.

Empower the Olympic industry and help efficient operation:

In the preparation and operation process of the Paris Olympic Games, the key links such as sewage treatment, venue facility maintenance, food safety and waste management put forward extremely high requirements for the efficiency and stability of equipment.Bonvestainless steel lobe pumpsstand out in these areas thanks to their non-clogging, low shear, and strong self-priming capabilities. From ensuring the stable operation of swimming venues and efficiently handling all kinds of waste generated during the Olympic Games, Bonve Lobe Pumps provides a solid backing for the smooth holding of the Olympic Games with its excellent performance.

Technological innovation leads, showing the industry frontier:

The research and development of Bonve stainless steel lobe pumps area model of the deep integration of technological innovation and market demand. Its original fourth-generation pump structure not only significantly improves the corrosion resistance and sealing performance of the material, but also ensures the low energy consumption and long life of the pump under efficient operation, and accurately matches the stringent requirements of the Olympic Games for high efficiency, energy saving andenvironment

Ningbo Bonve Pumps Co., Ltd. (hereinafter referred to as "Bonve Pumps") is on a mission to revolutionize its manufacturing process by integrating cutting-edge technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI).

On November 26, 2024, Bonve Pumps joined forces with Jing Shi Industrial to officially launch the planning project for their new smart factory.

Attending the project's kickoff meeting were Mr. Tan, General Manager of Bonve Pumps, Manager Sun, and project team members, along with Mr. Zhang from Jing Shi Industrial.

In today's globalized world, smart manufacturing is emerging as the new engine of industrial development, driving profound changes in the manufacturing sector.

National strategies such as Germany's "Industry 4.0," China's "Made in China 2025," and the United States' "Advanced Manufacturing Partnerships" all highlight the imperative of intelligent manufacturing in future competitiveness.

We are set to harness this wave of progress and sail forward.

This project aligns with China's "Made in China 2025" strategic plan and is a crucial driver for the high-quality development of Bonve Pumps in the general equipment industry.

A Monumental Endeavor:

We are well aware of the immense responsibility and honor that comes with such a technologically, innovatively, and strategically significant project.

It is not just about upgrading production lines;it is a symbol of our collective wisdom and hard work.

Here, every process will be optimized through advanced technologies, and each product will embody our commitment to quality and our responsibility to our customers.

General Manager's Perspective:

Reflecting on the past, General Manager Mr. Tan Liang said, "We have achieved remarkable results with innovation as our wings and quality as our foundation.

However, we understand that only through continuous innovation can we maintain our vitality.

Therefore, we have decided to invest in the construction of a modern factory that is efficient, environmentally friendly, and intelligent, enhancing our core competitiveness and making a graceful transition from traditional manufacturing to smart manufacturing.

This future smart factory will be more than a simple production line upgrade; it will be a testament to our dedication and hard work."

Technical Manager's Vision:

Imagine a fully operational new factory where robotic arms assemble parts with precision on the production line, intelligent logistics systems silently move between workstations, and our engineers monitor the entire production process in real-time through large screens, making adjustments and optimizations as needed.

This will not only greatly improve production efficiency but also create a safer and more comfortable working environment for our employees.

Of course, the realization of all this can't do without the joint efforts of every colleague present.

We need the creative sparks of our designers, the superb skills of our engineers, the efficient coordination of our management, and the enthusiastic participation of all our employees.

This is a team project and a major test of team spirit.

A New Beginning:

The success of this project is not the end but a new beginning.

It will bring us more opportunities and challenges and will undoubtedly become a milestone in our corporate development history.

Let us take this project launch as an opportunity to stay true to our original aspirations, forge ahead, and strive tirelessly to realize our dreams and ambitions!

In the food industry, Bonve pumps have become a key tool for enhancing production efficiency and product quality with their outstanding performance and innovative design. Here are some exciting applications of Bonve pumps in food processing that not only showcase the advancement of their technology but also provide tangible business value to food manufacturers.

Both colloid mill and homogenizer mixing pump can shear, emulsify, disperse, and mix materials, but in fact, colloid mill and homogenizer mixing pump are two kinds of equipment based on the principle, structure, and application.

Colloid mill is a kind of grinding equipment, suitable for materials with higher viscosity and larger particles. The working principle of the colloid mill is that the motor drives the rotor and the stator to rotate at a relatively high speed. When the processed material passes through the gap between the stator and the rotor, it is subjected to strong shearing force, frictional force, high-frequency oscillation and other physical effects. The material is effectively emulsified, dispersed and crushed to achieve the effect of fine crushing of the material.

Emulsification pump is a kind of emulsification equipment, which is suitable for materials with small particles. The working principle of the emulsification pump is that the material undergoes a series of processes such as strong shearing, impact and turbulence between the homogenizer rotor and the stator that rotate at a high speed, so that the material can withstand hundreds of thousands per minute in the narrow gap between the stator and the rotor. Times of hydraulic shear. The combined effects of centrifugal extrusion, impact and tearing can instantly evenly disperse and emulsify. After high-frequency cyclic reciprocation, high-quality products with no bubbles, fineness and stability are obtained.

From the above point of view, the difference between the two in terms of the refinement effect, the mixed homogeneous emulsification pump is better than the colloid mill. Generally, in many occasions, the colloid mill is used in the front of the emulsification pump or in the high In the case of viscosity, colloid mills are often used for refinement when there are many solid substances. Therefore, when choosing colloid mill and emulsification equipment, you still have to refer to your own production materials.

Bonve homogenizer mixing pump’s working chamber is composed of a total if 12 layers of three-stage rotor and stator. Proceed products are dispersed, refined and emulsified by the rotor and stator in stages. The pump is an high efficiency ultra-fine homogeneous pump with mixing, dispersion, breaking, dissolution, refinery, homogenization, emulsifying and transporting. The sealing of Bonve homogenizer mixing pump can be either double face or single face according to the properties of the processed materials. It also can have heating insulation or cooling device if required by the users.

Bonve homogenizer mixing pump is suitable for large and medium batch continuous online production or cyclic processing production process.

Email:trade@bonvepumps.com

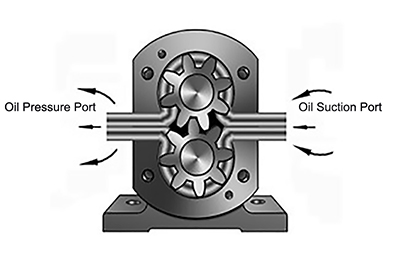

Gear pump is a positive displacement pump, which has a pair of meshing gears. One driving gear is driven to rotate by the motor, and the other driven gear is meshed with the driving gear to rotate. When the two gears are gradually separated, a partial vacuum will be formed. The liquid is inhaled through the suction pipe under the action of atmospheric pressure, and the inhaled liquid is squeezed and pushed out by the gear along the inner wall of the pump, which features small handling and high lift.

Gear pumps use conveying media as the lubricating medium in rotation, and are generally used in oily media, otherwise they will cause great wear and reduce the service life to a large extent.

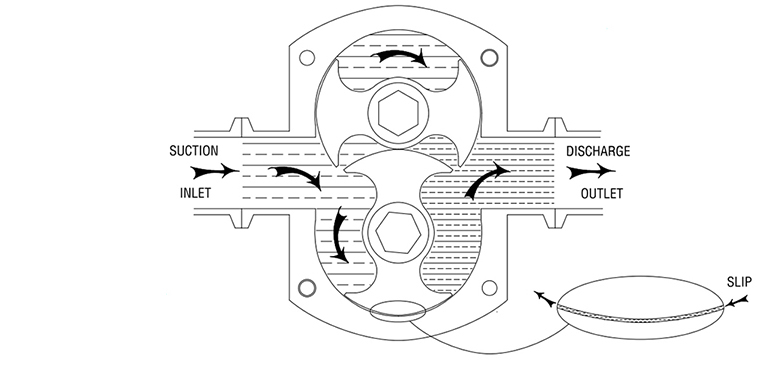

Rotary lobe pump consists of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing. There are basically no vulnerable parts during operation, and it is easy cleaning and maintenance. It is the first choice for customers in liquid transportation at present.

Rotary lobe pump is used to transport the medium according to the volume change between the rotor and the pump casing, and can transport the medium with viscosity below 100000 CP. Applicable in food, daily chemical industry, fine chemical industry, papermaking, medicine and pharmacy, environmental protection, petroleum and other fields.

Below table shows the main difference between gear pump and rotary lobe pump:

|

Details |

Rotary Lobe Pump |

Rotor Gear Pump |

|

Application |

High viscosity, high density, high solid products |

General for oil products |

|

Structure |

Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products. |

Gears mesh together, hard contact, wear. Flow efficiency decreases after wearing, short service life. |

|

Simple structure, low failure rate, easy to maintain. |

The front end has a shaft sleeve, which is easy to wear. The pump needs to be disassembled for replacement, and the maintenance is complicated. |

|

|

Spare Parts for Maintenance |

Mechanical seal and O-ring |

Mechanical seal and O-ring |

| / |

Shaft sleeve |

|

| / |

Gears |

Rotary lobe pump is more ideal to select for no frequent wearing parts to replace, easier maintenance and longer service life.

To find out more about Bonve rotary lobe pump, Click on the picture below

Email: trade@bonvepumps.com

Efficient Pumping Solutions in the Food Industry: Innovative Applications of Bonve Pumps

In the food industry, pumping technology is an indispensable part of the production process, which not only relates to the quality and consistency of the products but also directly affects production efficiency and costs.

Today, we will explore three innovative cases of Bonve pumps in the food sector, which demonstrate how carefully designed pumping solutions can meet specific needs.

Case 1: The Gentle Choice for Chocolate Factories

Chocolate is a product that is very sensitive to temperature and can easily coagulate at low temperatures.

To ensure the fluidity of chocolate during the transfer process and prevent coagulation, Bonve offers a jacketed rotary lobe pump.

This pump design allows for the circulation of heating media (such as steam or hot water) in the pump's jacket, thereby maintaining the temperature of the chocolate and ensuring its fluidity during the transfer process.

Features:

- Gentle Handling: Particularly suitable for handling shear-sensitive and delicate products.

- Efficient Starting: The heating system ensures smooth starting even in low-temperature environments.

- Hygienic Design: Meets hygiene standards, suitable for use in the food industry.

Case 2: Versatile Pumps for the Seasoning Industry

The seasoning industry requires a pump that can handle various viscosities and ingredients.

Bonve's food-grade lobe pumps, with their high hygiene standards and smooth internal surfaces, are the ideal choice for transferring seasonings.

Whether it's ketchup, barbecue sauce, or peanut butter, Bonve pumps can handle it with ease.Features:

- High Hygiene Standards: Manufactured from stainless steel 316 or 316L, with a surface roughness below 0.8μm.

- Easy to Clean: Meets CIP (Cleaning) and SIP (Sterilization) requirements, easy to disassemble and maintain.

- Low Wear: Low-speed operation reduces damage to the pumped products.

Case 3: Efficient Pumping in Meat Processing

In meat processing, there is a need for a pump that can handle highly viscous products such as semi-solid pastes or mixtures containing semi-solid pieces.

Bonve rotary lobe pump, with its enlarged rectangular inlet design, can efficiently handle these products.

The working principle of this pump and its powerful drive system ensure that the pump can output a strong driving torque at low speed, guaranteeing continuous, non-stagnant transfer.

Features:

- Gentle Handling: Gentle handling of viscous products such as meat slurry, which helps to maintain the product's texture and quality.

- High Efficiency: Provides a continuous flow of the product with minimal disruption.

- Easy Maintenance: Designed with minimal moving parts, making them easy to maintain and operate.

- Hygienic: Made of stainless steel, which is easy to clean and sanitize.

Through these cases, we can see the diverse applications of Bonve pumps in the food industry.

They not only improve production efficiency but also ensure the quality and consistency of the products.

Whether it's chocolate, seasonings, or meat processing, Bonve pumps are indispensable partners in the food industry.

In industries like chemicals, food, and cosmetics, moving liquids smoothly and safely is crucial—especially when those liquids are thick, abrasive, or even hazardous. At Bonve, we specialize in designing rotary lobe pumps that tackle these challenges head-on, ensuring your operations run efficiently without compromise. Let’s explore how our pumps solve real-world problems, even if you’re new to the world of industrial pumping!

Why Bonve Rotary Lobe Pumps Stand Out

Imagine a pump that works like a gentle hand, moving sticky honey, delicate creams, or even brittle chemicals without damaging them. That's exactly what Bonve pumps do. Here's what makes them unique:No Leaks, No Worries: Our pumps use advanced seals (like double-layered, water-cooled designs) to keep toxic or sensitive fluids securely contained. Think of it as a “safety vault” for your liquids.

Handles Thick or Thin Fluids with Ease: Whether it’s toothpaste-like sludge or watery solutions, our pumps adjust effortlessly. They even manage liquids that thicken over time, like drying paint or hardening glue.

Built to Last: Made from tough stainless steel, these pumps resist rust and corrosion, even when pumping harsh chemicals.

Easy to Maintain

Fewer parts mean less downtime. Open the pump, clean it quickly, and get back to work.

Real Success Story: Solving a Hydrogen Energy ChallengeA Canadian company developing hydrogen energy faced a major roadblock: pumping oxidized mercury, a toxic and sticky fluid that thickened as it moved through filters.

Their old pumps couldn’t keep up—flow rates dropped, parts wore out fast, and leaks posed safety risks.

Bonve’s Solution

We provided a stainless steel rotary lobe pump tailored to their needs:

Adapted to Changing Thickness: The pump smoothly handled mercury’s viscosity, from as thin as olive oil (500 cp) to thicker than molasses (4,000 cp).

No Clogs, No Jams: Custom rotors (shaped like wings or lobes) pushed through solids without getting stuck.

Zero Leaks, Full Safety: Double-sealed design ensured no toxic mercury escaped, protecting workers and the environment.

Certified Reliability: CE and ISO9001 certifications gave them peace of mind.

Result: The company’s production line ran smoothly, meeting deadlines and safety standards.

Where Bonve Pumps Shine

Our pumps aren’t just for chemicals—they’re versatile problem-solvers:

Food & Beverage: Gentle enough for chocolate, yogurt, or honey. No damage to flavors or textures!

Cosmetics: Perfect for creamy lotions, shampoos, or toothpaste. Keeps products smooth and bubble-free.

Cleaning Products: Handles thick detergents, soaps, and even abrasive slurries without wearing out.

Why Customers Trust Bonve

21+ Years of Expertise: Over 50,000 pumps in action worldwide.

Custom Solutions: Need a pump that handles gritty slurries or ultra-thick fluids? We’ll tweak the design to fit.

Fast Support: Standard pumps ship in 7 days. Got a unique challenge? Our engineers are ready to help.

Join Thousands of Satisfied Users

From detergent giants in Greece to cosmetic leaders in Australia, Bonve pumps power industries globally. Whether you’re making hydrogen fuel, crafting skincare products, or bottling sauces, we’ve got a pump that works as hard as you do.

Discover the Bonve difference today—where innovation meets simplicity.

Bonve: Engineered for Efficiency, Designed for Safety.

Are you looking to pump viscous food products like tomato sauce, mayonnaise, chocolate, or honey efficiently without compromising quality? In today’s competitive food industry, maintaining product quality while optimizing production costs is crucial. This is where the right pump technology becomes essential. Rotary lobe pumps, known for their gentle handling and efficient performance, are increasingly becoming the go-to solution for many food manufacturers.

Why Rotary Lobe Pumps Are Ideal for the Food Industry

Gentle Handling of Products

Rotary lobe pumps are designed to minimize product shear, preserving the integrity and quality of delicate food items like sauces and pastes. This gentle pumping action is particularly beneficial for products like chocolate, honey, and tomato sauce, ensuring they retain their texture and flavor throughout the process.

Versatility

These pumps can handle a wide range of viscosities and temperatures, making them suitable for various applications within the food industry. Whether you’re dealing with thick syrups or thin juices, rotary lobe pumps can manage the task efficiently.

Hygienic Design

Meeting stringent hygiene standards is critical in food processing. Rotary lobe pumps are constructed from high-quality, food-grade materials that are easy to clean and maintain. Their design ensures compliance with food safety regulations, making them ideal for maintaining a clean and safe production environment.

Efficiency and Reliability

Rotary lobe pumps provide consistent, smooth flow, reducing the risk of clogging and ensuring reliable performance. This efficiency translates to lower production costs and higher throughput, making them a cost-effective solution for food manufacturers.

Applications in Food Processing

Tomato and Chili Sauce Pumping

One of the common applications of rotary lobe pumps is in the production of tomato and chili sauces. Traditional pumps often struggle with maintaining product quality due to high shear rates. Rotary lobe pumps, with their low-speed operation, ensure that sauces are transferred gently, preserving their quality and consistency.

Dairy Products

Rotary lobe pumps are extensively used in dairy processing. They handle products ranging from milk and cream to thicker substances like yogurt and cheese. Their design ensures these products are pumped without compromising their quality or safety.

Beverage Industry

In the beverage sector, rotary lobe pumps are ideal for handling fruit juices, syrups, and concentrates. Their ability to handle high viscosities and particles without damaging the product makes them indispensable in this industry.

Key Benefits for Your Business

- **Improved Product Quality**: Gentle handling ensures that the texture and flavor of your products are preserved.

- **Increased Efficiency**: Efficient pumping reduces downtime and increases production throughput.

- **Cost Savings**: Durable construction and reliable performance translate to lower maintenance costs and extended equipment life.

- **Compliance with Hygiene Standards**: Easy-to-clean designs help you meet the highest hygiene standards, crucial for food safety.

Conclusion

Investing in a rotary lobe pump can significantly enhance your production process, ensuring that you deliver high-quality food products efficiently. Whether you are pumping sauces, dairy products, or beverages, the right pump technology can make all the difference.

For more detailed solutions tailored to your specific needs, explore our range of rotary lobe pumps.Discover how our advanced pumping solutions can transform your food production and help you maintain the highest standards of quality and efficiency.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2