Rubber dampeners are essential components in automotive suspension systems, specifically designed to minimize vibrations and absorb shocks. In this article, we will compare and contrast different products and services related to left-hand rubber dampeners, focusing on their application in cars. Whether you’re a car enthusiast or simply looking to improve your vehicle’s performance, this guide will help you make an informed decision.

1. Rubber Dampener Left Hand

The Rubber Dampener Left Hand is a versatile solution suitable for various car models. Its ergonomic design provides enhanced stability and vibration reduction. With its durable rubber material, this dampener effectively absorbs shocks, ensuring a smoother ride. Additionally, its left-hand orientation ensures a secure fit for optimal performance.

2. Shock Absorber Rubber Dampener

The Shock Absorber Rubber Dampener offers exceptional shock absorption capabilities, perfect for off-road adventures or bumpy terrains. Its specialized design helps maintain stability during high-speed driving and intense cornering. With its reinforced rubber construction, this dampener is built to withstand heavy-duty usage, providing reliable performance for your automotive needs.

3. Automotive Rubber Dampener Left Hand

Designed explicitly for automotive applications, the Automotive Rubber Dampener Left Hand excels in delivering superior vibration reduction. Its advanced technology ensures precision engineering, resulting in optimal ride comfort and handling. This dampener’s left-hand orientation guarantees a secure and proper fit, ensuring maximum effectiveness in reducing vibrations and shocks.

4. Rubber Dampener Left Hand for Car

If you’re specifically looking for a rubber dampener tailored to car usage, the Rubber Dampener Left Hand for Car fits the bill perfectly. This dampener offers a seamless installation process, with a left-hand orientation designed to fit most popular car models. Its high-quality rubber construction effectively absorbs shocks, reducing noise and vibrations for a quieter and smoother driving experience.

Overall, all the mentioned rubber dampeners provide reliable performance and shock absorption capabilities. The choice between them ultimately depends on your specific requirements, such as the intensity of driving conditions, car model compatibility, and personal preferences.

To ensure optimal results, it is recommended to consult with a qualified automotive professional or refer to your vehicle’s manual for specific guidance when selecting and installing rubber dampeners.

In conclusion, by incorporating a suitable rubber dampener, you can significantly improve your car’s suspension system, leading to enhanced comfort and increased vehicle longevity. Evaluate your needs, consider the options mentioned above, and make an informed decision to elevate your driving experience.

Are you constantly in situations that put your fingers at risk of injury? Whether you work in a physical job or enjoy adventurous hobbies, protecting your fingers should be a top priority. Introducing the Rubber Finger Protective Cover - a simple yet effective solution to keep your fingers safe and injury-free.

Why Choose Rubber Finger Protective Covers?

Versatile Protection: These rubber finger covers are designed to fit snugly over your fingers, providing a protective barrier against a wide range of potential hazards. From cuts and scrapes to burns and bruises, these covers offer all-around protection for your fingertips.

Durable and Long-Lasting: Made from high-quality rubber, these protective covers are built to withstand rigorous use. Whether you’re working in oil, chemicals, or rough surfaces, these covers can handle it all. Their sturdy construction ensures they won’t easily tear or wear out, guaranteeing long-lasting finger protection.

Comfortable Fit: The Rubber Finger Protective Covers are designed for maximum comfort. The flexible rubber material allows for a snug yet breathable fit, ensuring ease of movement while wearing them. They are lightweight and won’t hinder your finger dexterity, allowing you to perform tasks with precision and agility.

Easy to Use: Putting on and taking off these finger covers is a breeze. They have a stretchable design that makes them suitable for various finger sizes. Simply slide them onto your fingertips and adjust them as needed for a secure and comfortable fit. No complicated straps or buckles required.

Bright Yellow Color: These covers come in an eye-catching yellow color, providing enhanced visibility in dimly lit environments. The vibrant hue also makes them easy to spot if dropped or misplaced. Never lose sight of your finger protection again!

Applications of Rubber Finger Protective Covers

The versatile nature of Rubber Finger Protective Covers makes them suitable for a wide range of applications. Here are a few scenarios where these protective covers can be incredibly useful:

Industrial Work: If you work in an industry involving machinery, tools, or equipment with sharp edges, these protective covers are a must-have. They act as a barrier against potential cuts and abrasions, ensuring your fingers remain safe and functional.

Craftsmanship: Whether you are an artisan, carpenter, or jewelry maker, delicate tasks require precision and steady hands. Rubber Finger Protective Covers offer the protection needed without sacrificing tactile sensitivity or fine motor skills.

Outdoor Activities: From gardening and woodworking to fishing and camping, outdoor activities can expose your fingers to various risks. Donning Rubber Finger Protective Covers ensures your fingers are shielded from sharp thorns, rough surfaces, and potential injuries caused by tools or objects.

Conclusion

Don’t let the fear of finger injuries hold you back from doing what you love. Invest in the Rubber Finger Protective Cover to ensure your fingers are safeguarded from potential harm. These versatile, durable, and comfortable finger covers are suitable for various applications, providing you with the confidence and peace of mind to tackle any task. Get your Rubber Finger Protective Covers today and protect your most valuable tools - your hands!

EPDM rubber gasket sealer plays a critical role in ensuring the longevity and functionality of automotive lamps. As an automotive lamps rubber parts enthusiast, you understand the importance of maintaining the integrity of your vehicle’s lighting system. In this article, we will share valuable tips and tricks for using EPDM rubber gasket sealer effectively, helping you achieve optimal results.

1. Clean the Surface Thoroughly

Before applying the EPDM rubber gasket sealer, it’s crucial to clean the surface of the automotive lamp completely. Any dirt, dust, or old sealant residue can compromise the adhesion of the sealer. Use a mild detergent and water to gently clean the area, ensuring a clean and dry surface.

2. Use Proper Application Techniques

To ensure a secure and watertight seal, apply the EPDM rubber gasket sealer evenly along the gasket channel of the automotive lamp. Use a small brush or applicator to spread the sealer uniformly. Avoid over-application, as excessive sealer can interfere with the lamp’s fitment.

3. Allow Sufficient Curing Time

EPDM rubber gasket sealer requires adequate curing time to reach its full sealing potential. Read the instructions provided by the manufacturer and follow the recommended curing duration. Avoid exposing the fresh sealant to moisture or extreme temperatures during this period.

4. Regular Inspection and Maintenance

To extend the lifespan of your automotive lamps, it’s essential to perform regular inspections. Check for any signs of wear, damage, or loosening of the EPDM rubber gasket sealer. If necessary, reapply the sealer or replace the gasket to ensure optimal performance.

5. Store the Sealer Properly

Proper storage is crucial to maintain the quality of the EPDM rubber gasket sealer. Seal the container tightly after each use to prevent any air or moisture exposure. Store the sealer in a cool, dry place, away from direct sunlight.

6. Choose High-Quality Sealer

Investing in a high-quality EPDM rubber gasket sealer is vital to achieve long-lasting results. Research different brands and read customer reviews to find a reliable and durable product. Opt for a sealer specifically designed for automotive applications to ensure compatibility and performance.

7. Follow Safety Precautions

When working with EPDM rubber gasket sealer, always follow the safety precautions outlined by the manufacturer. Wear protective gloves and goggles to protect your skin and eyes. Avoid inhalation or ingestion of the sealer, and work in a well-ventilated area.

By following these tips and tricks, you can confidently use EPDM rubber gasket sealer black for automotive lamps, ensuring a secure and leak-free seal. Regular maintenance and inspections will help you catch any potential issues early on, resulting in safer and more durable automotive lighting. Remember, a little effort in maintaining your rubber parts can go a long way in enhancing your driving experience.

If you’re an automotive engine enthusiast, you understand the importance of every part that contributes to your car’s performance. One such essential component is the rubber corrugated air intake hose. While it may seem like a small and insignificant part, this hose plays a critical role in maintaining the engine’s efficiency and longevity.

Superior Flexibility and Durability

One of the key advantages of a rubber corrugated air intake hose is its exceptional flexibility. Engine compartments are known for their confined spaces and complex designs, making it essential for the intake hose to adapt to various angles and bends. The corrugated design of this hose allows it to flex and twist without compromising its integrity, ensuring optimal airflow to the engine.

In addition to flexibility, this type of hose offers remarkable durability. It is subjected to high temperatures and constant exposure to engine fluids and chemicals, making it prone to wear and tear. However, the rubber used in its construction possesses excellent heat resistance and can withstand harsh conditions. This durability ensures that the hose remains intact and functional even in extreme operating conditions, making it a reliable choice for automotive engine enthusiasts.

Enhanced Performance and Efficiency

By facilitating the proper intake of air, the rubber corrugated air intake hose contributes significantly to the engine’s performance. A smooth and uninterrupted airflow allows the engine to breathe efficiently, resulting in improved combustion, power delivery, and overall performance. With this hose in place, you can expect enhanced throttle response, increased horsepower, and better fuel efficiency.

Moreover, the corrugated design of the hose helps to reduce turbulence within the intake system. This promotes a smoother airflow, minimizing pressure drops and increasing overall efficiency. By optimizing the air-to-fuel ratio, the intake hose helps the engine deliver its maximum potential without overworking any other components.

Easy Installation and Maintenance

Another advantage of this rubber intake hose is its straightforward installation process. It is designed to fit seamlessly into the engine’s intake system, ensuring a tight and secure connection. With clear instructions and a few basic tools, any automotive enthusiast can replace an old or worn-out hose with ease.

Furthermore, maintenance becomes hassle-free with a rubber corrugated air intake hose. Its durable construction eliminates the need for frequent inspections or replacements. Simply check for any signs of damage or deterioration during routine engine maintenance, and if required, replace the hose to ensure optimal performance.

Conclusion

While seemingly inconspicuous, the rubber corrugated air intake hose for car engines offers a range of unique features and benefits that contribute to enhanced performance and durability. Its flexibility, durability, and ability to optimize airflow make it an indispensable part of every automotive engine. By investing in a high-quality rubber corrugated air intake hose, you can ensure that your engine performs optimally, delivering the power and efficiency you desire.

Are you an automotive enthusiast looking to enhance your engine’s performance? The ignition coil plays a crucial role in delivering power to your engine’s spark plugs. A well-maintained ignition coil ensures efficient combustion and optimal engine performance. In this article, we will share some valuable tips and tricks to help you maintain and get the most out of your automotive engine rubber ignition coil.

Regular Inspection: Start by inspecting your ignition coil for any visible signs of damage, such as cracks or wear. Look for any loose connections or rust on the coil and surrounding components. Regular inspection will help you identify potential issues before they escalate.

Clean Connections: Ensure that the connections between the ignition coil and spark plugs are clean and secure. Over time, dirt and debris can accumulate, leading to poor connectivity and decreased performance. Using a brush or compressed air, gently clean the connections to ensure a reliable and consistent electrical flow.

Check Voltage: Use a multimeter to measure the voltage output of your ignition coil. A healthy coil should produce a consistent voltage within the manufacturer’s specified range. If you notice any irregularities or a significant drop in voltage output, it may be time to replace your ignition coil.

Inspect Rubber Boots: The rubber boots on the ignition coil are crucial for protecting it from moisture and debris. Check for any cracks or tears in the boots and replace them if necessary. Damaged boots can lead to moisture buildup and eventually cause the coil to malfunction.

Avoid Heat Damage: The ignition coil generates heat during operation. To prevent overheating and potential damage, ensure that the coil is not blocked or covered by any nearby components. Adequate airflow around the coil is crucial for maintaining optimal operating temperatures.

Protect from Moisture: Moisture is one of the main enemies of the ignition coil. Protect it from moisture by using silicone spray or dielectric grease on the connections. This will help repel water and prevent corrosion, ensuring a longer lifespan for your ignition coil.

Replace Aging Coils: Ignition coils have a limited lifespan and tend to degrade over time. If your vehicle has been experiencing misfires, rough idling, or decreased fuel efficiency, it may be a sign that your ignition coil is nearing the end of its lifespan. Consider replacing it to restore your engine’s performance.

Quality Matters: When it comes to automotive engine rubber ignition coils, quality matters. Invest in a high-quality coil from reputable brands to ensure durability and performance. Cheap, low-quality coils may save you money upfront, but they can lead to frequent failures and costly repairs down the line.

By following these tips and tricks, you can ensure that your automotive engine rubber ignition coil performs at its best and delivers optimal engine performance. Regular maintenance, inspections, and replacing aging coils are key to avoiding engine issues and enjoying a smooth and efficient driving experience.

Remember, a well-maintained ignition coil not only enhances your engine’s performance but also extends the lifespan of other components. So, invest your time and effort in maintaining this essential part of your vehicle’s ignition system.

Are you an automotive enthusiast who craves the exhilaration and thrill of a smooth and stable ride? Look no further. Introducing the Automotive Suspension Black Rubber Damping Sleeve, a revolutionary innovation in the world of automotive suspension rubber parts. In this blog post, we will delve into the unique features and exceptional benefits that make this damping sleeve an essential component for all suspension aficionados.

1. Unparalleled Shock Absorption

The Automotive Suspension Black Rubber Damping Sleeve boasts exceptional shock absorption capabilities, effectively reducing the vibrations and impacts experienced during your ride. Its premium-quality black rubber composition is specifically engineered to dissipate and dampen the forces generated, resulting in a smooth and comfortable driving experience. Say goodbye to those jolts and jerks when traversing uneven terrains.

2. Enhanced Stability

One key advantage of the Automotive Suspension Black Rubber Damping Sleeve is its ability to enhance the overall stability of your vehicle. By providing a secure and cushioned connection between various suspension components, it minimizes unnecessary movements and ensures that your vehicle remains firmly grounded. Experience an enhanced sense of control and stability, even during high-speed maneuvers or tight cornering.

3. Long-lasting Durability

Built to withstand the test of time, this damping sleeve exhibits exceptional durability. Crafted from high-quality rubber materials, it can withstand extreme temperatures, harsh weather conditions, and regular wear and tear. No matter the road conditions or driving habits, the Automotive Suspension Black Rubber Damping Sleeve remains steadfast, allowing you to enjoy a hassle-free ride for years to come.

4. Precision Fit and Easy Installation

Designed with precision and compatibility in mind, the Automotive Suspension Black Rubber Damping Sleeve ensures a perfect fit for a wide range of vehicles. Its innovative design allows for effortless installation, saving you valuable time and effort. With no need for specialized tools or professional assistance, you can easily replace your worn-out damping sleeves and experience the unparalleled benefits right away.

5. Cost-effective Solution

Investing in the Automotive Suspension Black Rubber Damping Sleeve is a wise choice not only for its remarkable performance but also for its cost-effectiveness. With its extended lifespan and ability to enhance the longevity of other suspension components, this damping sleeve helps minimize maintenance and repair costs in the long run. Experience the advantages of a smooth ride at an affordable price.

In conclusion, the Automotive Suspension Black Rubber Damping Sleeve is a game-changer in the realm of automotive suspension rubber parts. Its unique features, ranging from unparalleled shock absorption and enhanced stability to long-lasting durability and easy installation, make it an indispensable component for every suspension enthusiast. Embrace the power of smooth and stable rides with this exceptional damping sleeve. Don’t settle for anything less when it comes to your automotive experience. Upgrade to the Automotive Suspension Black Rubber Damping Sleeve today and revolutionize your driving pleasure.

Are you looking for high-quality stable mats that combine durability, style, and sustainability? Look no further than Recycled Rubber Stable Mats. These black rubber mats are not only aesthetically pleasing but also provide numerous benefits for both horses and horse owners. In this blog post, we will delve into the features and advantages of using Recycled Rubber Stable Mats for your stables, whether it’s a racecourse or a personal equestrian facility.

The Benefits of Recycled Rubber Stable Mats

1. Durability and Longevity

Recycled Rubber Stable Mats are designed to withstand heavy use and provide long-lasting performance. Made from high-quality recycled rubber, these mats offer exceptional durability and are resistant to wear and tear. Whether your horses are active in their stalls or the stables are used for public events, these mats will hold up under pressure, ensuring their longevity and saving you money in the long run.

2. Enhanced Comfort and Safety

Providing a comfortable and safe environment for horses is crucial. The cushioning effect of Recycled Rubber Stable Mats helps to reduce strain on horses’ joints, minimizing the risk of injuries. These mats also offer excellent traction, preventing slips and skids, so your horses can move around with confidence. With Recycled Rubber Stable Mats, you can be confident that your horses are comfortable and safe in their stalls.

3. Noise and Odor Reduction

Stables can often be noisy spaces, with horses moving around and hooves striking the ground. Recycled Rubber Stable Mats are designed to absorb sound and reduce noise levels, creating a quieter and more relaxed environment. Additionally, these mats have excellent odor-reducing properties, keeping your stables fresh and more pleasant for both horses and caretakers.

4. Easy Installation and Maintenance

Installing Recycled Rubber Stable Mats is a breeze. These mats are easy to handle and fit seamlessly together, ensuring a professional and clean appearance. They can be easily trimmed to fit any size of stall, making the installation process hassle-free. Additionally, these mats require minimal maintenance, allowing you to save time and effort while keeping your stables in top condition.

Stylish and Versatile: Black Rubber Stable Mats

In addition to their functionality, Recycled Rubber Stable Mats are available in a stylish black color. Black rubber mats add a touch of elegance to your stables, creating a polished and professional look. Whether you have a rustic-themed equestrian facility or a contemporary racecourse, the sleek appearance of black rubber mats will complement any style or design.

Conclusion

Recycled Rubber Stable Mats offer the perfect combination of durability, style, and sustainability. With their ability to withstand heavy use, provide comfort and safety, reduce noise and odors, and their easy installation and maintenance, these mats prove to be the ideal choice for any stable owner. Whether you have a racecourse or a personal facility, investing in Recycled Rubber Stable Mats will elevate the overall experience for both horses and caretakers. Choose sustainability without compromising on quality, and make your stables stand out with these versatile and stylish black rubber mats.

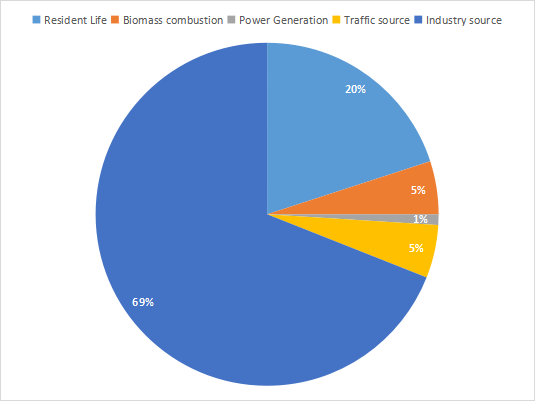

At present, industrial pollution is the largest source of PM2.5 in China, with cement manufacturing, coal-fired power plants, and steel metallurgy being the 3 major culprits among industrial pollution sources. Therefore, industrial filtering cannot be ignored in the management of PM2.5.

Sources of PM2.5

(Source: IPE)

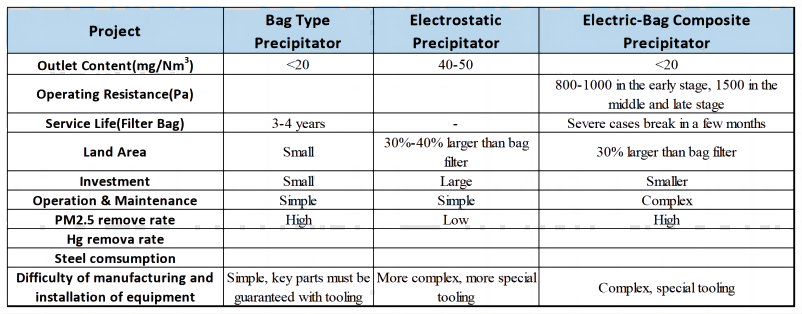

However, industrial filtering is not an easy task, because industrial fumes are hot and often contain acidic and alkaline gases, which require high requirements for the technology and materials used for industrial filtering. At present, there are two mainstream technologies for industrial dust removal, namely electrostatic precipitator and bag type precipitator. Based on these two, electric bag composite precipitator is derived.

Comparison of Economic Performance of Three Dust Collector Technologies

Bag Filter - The mainstream technology for industrial dust control: Currently, electrostatic precipitator technology in China has reached the stage of mature application, bag filter technology is in a period of rapid development. However, as the national requirements for controlling industrial flue gas pollution continue to improve, electrostatic precipitator technology alone cannot fully meet the requirements. The use of bag filter technology and electrostatic bag composite dust collectors as replacements for electrostatic precipitator technology has become mainstream.

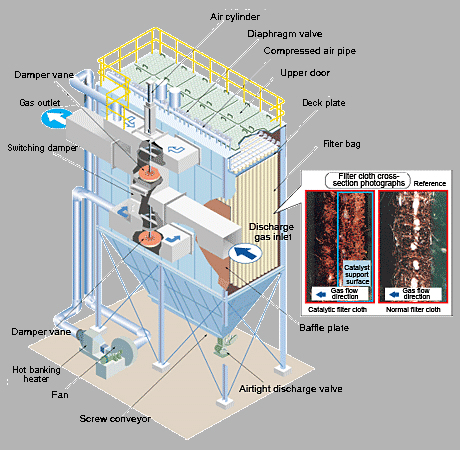

Mechanism of bag filters: Special fibers are used to make filter bags, and the dusty gas is injected into the bags, where the dust is filtered and captured. The filtering effect depends on the quality of the filter bags.

Structure of Bag Filter

(Source: Hitachi Plant Construction, Ltd. 56 )

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓

Contact us now!

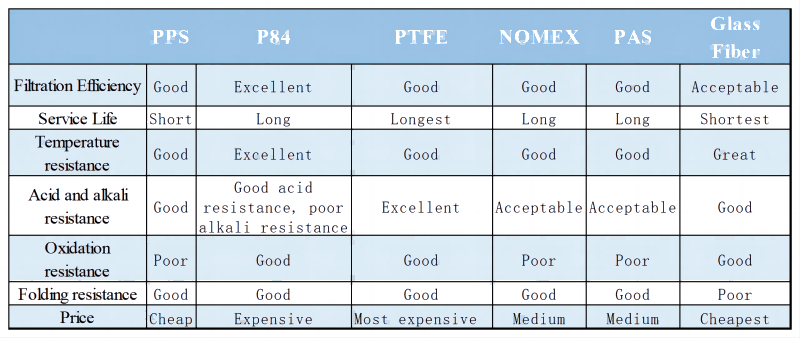

High temperature Filter Material - The core material of bag filters

The filtering effect of bag filters is achieved through filtering materials. Different filtering effects can be achieved by equipping various types of filter bags with different properties, such as resistance to normal temperature(<130℃), resistance to high temperature(>130℃), corrosion resistance, water and oil repellent, fire and explosion prevention, and long service life (2-4 years). The changes and innovations in bag filter technology are closely related to the transformation of filter materials.

Currently, the main high-temperature filter fibers used for flue gas treatment domestically and internationally include PPS (polyphenylene sulfide), Nomex (aromatic polyamide), P84 (polyimide), PTFE (polytetrafluoroethylene), glass fibers, and PSA (polyphenylene sulfone) fibers. In practical applications, multiple fibers are often used in combination. Production processes include needle punching, surface coating, emulsion impregnation, etc., which can achieve surface filtration and gradient filtration effects. This not only improves the dust collection efficiency but also reduces pressure loss, facilitates dust cleaning, and saves energy consumption.

Introduction to Major High-Temperature Filter Media

1. Polyphenylene Sulfide (PPS) - The most widely used high-temperature filter material

Polyphenylene sulfide fiber, with stable chemical properties, a high melting point (285°C), and excellent heat resistance. It also exhibits outstanding flame retardant, chemical resistance, and stability. It is mainly used in pulse bag filters for municipal waste incinerators, utility boilers, coal-fired boilers, hospital incinerators, and co-generation boilers. PPS is the most widely used high-temperature filter material.

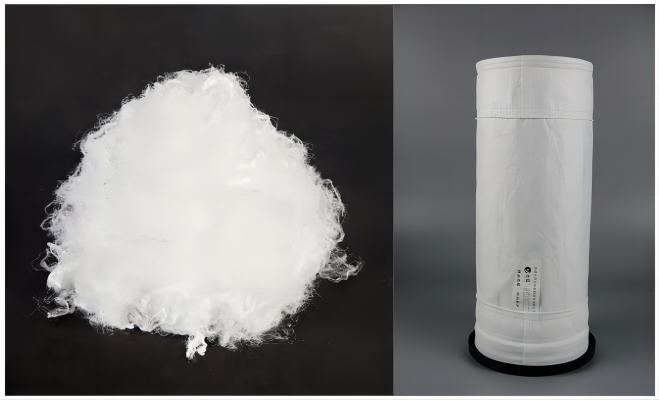

PPS fiber & PPS filter bag

From a global perspective, in 2012, PPS was mainly used in the automotive field, with 33% consumed in Japan and 50% consumed in Europe. In China, the consumption structure is primarily focused on environmental protection industries (filter bags), accounting for about 30%, followed by automotive components and the electronics/electrical industry.

2. Polyimide Fiber (P84) - The highest temperature-resistant dust removal material

Polyimide fiber, also known as aromatic polyimide fiber, is a high-performance fiber obtained by polymerizing pyromellitic dianhydride and aromatic diamine to form polyamide acid prepolymer, followed by solution spinning.

Polyimide fiber, originally developed by Lenzing AG in Austria, is commercially known as "P84." This monopolistic product is now owned by Evonik Industries in Germany and is mainly used in dust removal bags, earning it the nickname "Golden Silk"

P84 fiber P84 filter bag

Polyimide fiber has excellent comprehensive properties, including high temperature resistance, good filtration performance, and resistance to acid and alkaline substances. It can be used in high-temperature environments such as cement kiln tails, waste incineration, and power plants.

In addition, polyimide fiber products have a unique fiber structure - irregular leaf-shaped cross-sections, which increase the surface area by 80% compared to regular circular cross-sections. This brings two major advantages:

- Enhanced dust capture capability;

- The irregular fiber cross-sections naturally curl due to different internal stress levels and uneven distribution, providing strong entanglement force. Therefore, adding polyimide fiber to glass fiber composite needle-punched felts prevents easy shedding of the felt layer even at higher wind speeds.

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓

3. Polytetrafluoroethylene (PTFE) Fiber - The best corrosion-resistant dust removal material

Polytetrafluoroethylene fiber, also known as "PTFE" or "fluoro fiber" in China. It was first developed by DuPont in 1953 and achieved industrial production in 1957. Polytetrafluoroethylene fiber is a synthetic fiber made from polytetrafluoroethylene raw material through spinning or film production, followed by cutting or staple fiber processing. Currently, there are four main production methods for polytetrafluoroethylene fiber, including emulsion spinning and paste extrusion spinning.

PTFE fiber PTFE filter bag

Polytetrafluoroethylene fiber inherits many advantages of polytetrafluoroethylene, such as excellent chemical stability, a wide range of operating temperatures, resistance to atmospheric aging, radiation resistance, and low permeability. It is mainly used as high-temperature dust filter bags, filter media resistant to strong corrosive gases or liquids, filler materials for pumps and valves, sealing tapes, self-lubricating bearings, reinforcing materials for alkaline full-fluoride ion exchange membranes, and rocket launch tower covers.

There are two forms of polytetrafluoroethylene dust filter bags: one is where polytetrafluoroethylene fibers are coated on other filter materials (such as PPS fibers, P84 polyimide fibers, glass fibers, etc.) to form a base cloth, and the other is where both the coating and base cloth are made of polytetrafluoroethylene fibers and processed into needle-punched felts. The performance of 100% polytetrafluoroethylene fiber filter bags is superior. Despite their excellent performance, the relatively high price of polytetrafluoroethylene fibers is a barrier to their widespread promotion.

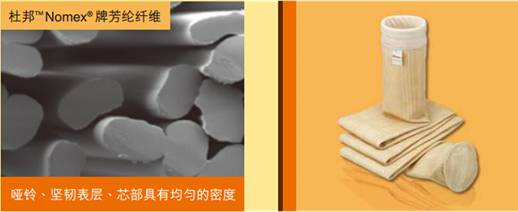

4. Nomex Fiber - The most widely used dust removal material

Nomex (Aramid) fiber is a high-performance synthetic fiber initially developed by DuPont. It possesses excellent properties such as high strength, high modulus, high temperature resistance, acid and alkali resistance, lightweight, and heat resistance. It finds wide applications in various fields. Currently, commercially available aramid varieties include meta-aramid and para-aramid, as well as a small amount of modified products such as aramid II and aramid III.

NOMEX fiber NOMEX filter bag

Meta-aramid exhibits high temperature resistance, flame retardant, and insulation performance. It is mainly used in high-temperature protective clothing, electrical insulation, and high-temperature filtration. Para-aramid, on the other hand, is primarily utilized for its high strength and modulus properties in personal protection, bulletproof armor, mechanical rubber products, high-strength ropes, and asbestos substitutes.

The high-temperature dust removal field is the main consumption market for meta-aramid. However, due to its cost-effectiveness compared to glass fiber and PPS, the market share of aramid fiber in the high-temperature filtration industry is only around 5%. One outstanding characteristic of aramid fiber filter bags in high-temperature applications is their extremely low shrinkage rate, maintaining a 1% shrinkage rate even after 1000 hours of use at 250°C.

5. Polyarylsulfone Fiber (PES) Introduction

Polyarylsulfone fiber belongs to the para-aramid series, scientifically known as polyphenylsulfone diphenylamine fiber. It is an aromatic polyamide fiber with sulfone groups (-SO2-) on the polymer backbone, making it a terpolymer.

PES filter bag

Polyarylsulfone fiber is an excellent material for manufacturing filter bags for baghouse dust collectors. It exhibits good heat resistance and excellent stability against thermal oxidation aging. It has low thermal shrinkage, maintains good dimensional stability, and possesses excellent acid resistance. It can be used for long periods at high temperatures and is particularly suitable for high-temperature filtration media.

Additionally, it is relatively cheaper compared to P84, PPS, and Nomex. The friction coefficient of polyarylsulfone fiber is low, making the resulting filter bags easy to clean. Its high temperature resistance allows it to be thermally bonded with PTFE (curing temperature of 260°C) to produce effective and stable laminated filter media.

6. Fiberglass - The most economical high-temperature filter material

Fiberglass is a traditional filter material and the most widely used filter material in medium to high-temperature flue gas filtration. Glass fibers can be classified into two main categories based on their glass composition: C-glass (alkali-containing) and E-glass (alkali-free) filter materials.

Fiberglass and Fiberglass filter bag

Fiberglass exhibits excellent high-temperature resistance and can operate for long periods under temperature conditions of 260°C (C-glass) / 280°C (E-glass). They can withstand instantaneous temperatures of up to 350°C. With high strength and low elongation, glass fibers have higher tensile strength than other natural and synthetic fibers. They also possess excellent corrosion resistance, except for corrosion by hydrofluoric acid. The smooth surface of glass fibers results in low filtration resistance, facilitating dust removal.

They are non-combustible and do not deform. Glass fibers treated with different surface agents have advantages such as softness, smoothness, hydrophobicity, anti-condensation, and low shrinkage. Glass fibers have outstanding dimensional stability, high tensile strength, strong corrosion resistance, smooth surface, air permeability, ease of dust cleaning, and good chemical stability. Due to their low cost, when cost is a priority for users, dust collection equipment manufacturers also use glass fibers for pulse bag filters.

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓

Contact us now!

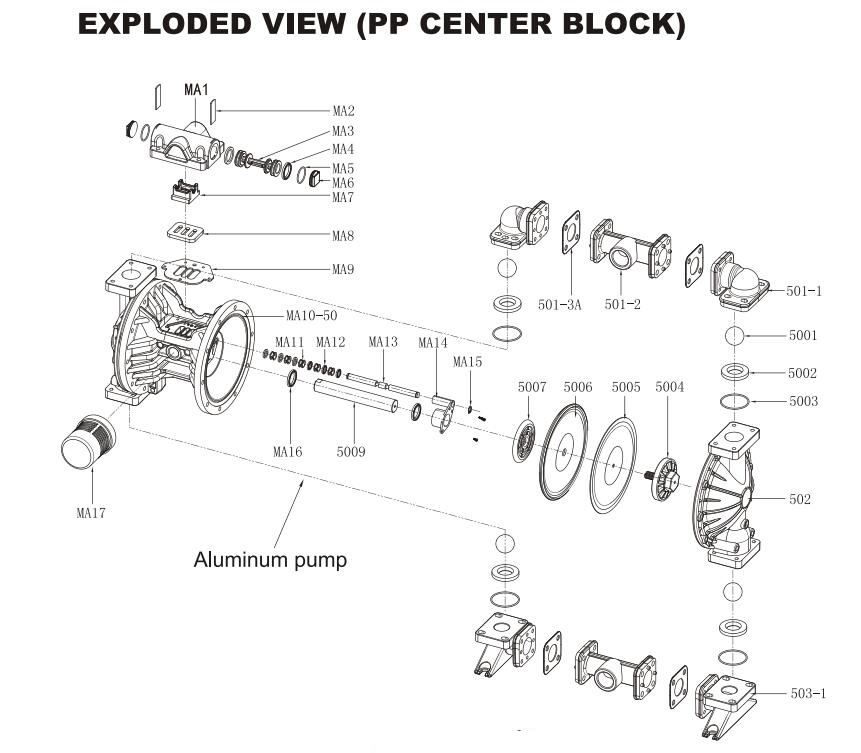

The role of air operated diaphragm pump has been greatly appreciated by people in the industry. Because the pneumatic diaphragm pump plays an important role in the transportation of dangerous and corrosive media, how should it be used correctly to increase the service life of the pneumatic diaphragm pump? What are the methods of use?

1. Installation and startup:

Place the air membrane pump as close to the product as possible, so that the suction pipeline is short and the number of configured parts is reduced. Do not reduce the pipeline diameter. In order to extend the life of the diaphragm, keep the pump as close as possible to the liquid being pumped. When the inlet pressure exceeds 10 feet (3 meters) of liquid column, a pressure relief adjustment device needs to be installed to extend the life of the diaphragm. If hard piping is installed, use a short length of flexible connection between the pump and the pipe. Flexible connection can reduce vibrations and twists in the pipes, and use a surge tank to further reduce pulsations in the fluid.

2. Supply air to the pneumatic diaphragm pump:

The air supply pressure of the pneumatic diaphragm pump shall not exceed 7KG pressure. Setting the pressure within 1~6KG can increase the service life of the diaphragm. Connect the air inlet of the pump to an air source with sufficient capacity and pressure that meets the design requirements. If the air supply line is hard pipe, install a short length of flexible connection between the pump and the air pipe to reduce twisting. In addition to the air inlet cover, the weight of the air inlet pipe and pressure regulating filter must also be supported in some way. Failure to support the piping may damage the pump. A pressure regulating valve must be installed to ensure that the air supply pressure does not exceed the specified range.

3. Inspection before operation:

Before working on the diaphragm pump, check all fixings to prevent looseness, tighten the loose places to avoid leakage, and fix them with the method described in the card attached to the pump.

4. Air intake and starting:

When starting, the air valve opens about 1/2 to 3/4 turn. After the pump is started, open the air valve to increase the air flow to achieve the required flow rate.

5. Exhaust:

If the diaphragm is broken, the liquid or air will enter the air port of the pump and be discharged into the atmosphere. When extracting dangerous or toxic substances, pipes need to be discharged to a suitable place for safe treatment. If the pump is submerged in the liquid, the air must be discharged from the liquid surface, and the exhaust pipe cannot be smaller than 1" (2.45CM). Reducing the diameter of the air pipe will limit the air flow and reduce the utilization rate of the pump. When the liquid level is high When using a pump, the discharge port needs to be at a higher place to prevent siphoning. Under certain temperatures and humidity, the discharged air may freeze. Using air drying can eliminate most of these problems.

6. After use:

If it is used to transport easily solidified liquid, in order to prevent damage to the pump, the pump must be thoroughly cleaned after each use. (Product left in the pump after use has dried or stuck to the pump, causing problems with the diaphragm and valves before the next start-up). In freezing temperatures, the pump must be drained after any use.

Troubleshooting Pneumatic Diaphragm Pumps

1. Before disassembling the pneumatic diaphragm pump, mark the left and right air chambers and liquid chambers respectively to facilitate subsequent reassembly.

2. Use a wrench to loosen the small clamp connecting the outlet pipe and the liquid chamber. The valve ball and seat can be seen after removing the outlet pipe. Then take out the ball and seat and check other spare parts of the pump whether have wear, chemical corrosion, cracks phenomenon or not.

3. Use a wrench to separate the liquid chamber and the intermediate body of the pump. The diaphragm and diaphragm splint can be seen after removing the liquid chamber.

4.Use tools or wrenches to fix the left and right edges of the outer plywood of the diaphragm to separate the diaphragm device from the intermediate body. Then loosen the diaphragm assembly by turning it clockwise. After removing the outer clamping plate of the diaphragm, take the shaft out of the intermediate body.

5. Use clamps to separate the shaft from the diaphragm device, and check whether the shaft, splint, and diaphragm have damaged and corroded phenomenon or not.

6. Install from step 5 to step 1

Please tell us your requirement and liquid, We have professional team to provide full-service solution that can help you find right solution from start to finish.

The shock absorber rubber dampener plays a crucial role in providing a smooth and comfortable ride by reducing vibrations and noise in your vehicle. If you’re new to using automotive shock absorber rubber dampeners, this step-by-step guide will help you understand how to install and maintain them correctly.

Step 1: Gather the necessary tools and materials

Before you begin, make sure you have all the tools and materials you’ll need to complete the installation. These may include a wrench, socket set, jack stands, and of course, the new shock absorber rubber dampener for the left side of your vehicle.

Step 2: Prepare your vehicle

Start by parking your vehicle on a level surface and engaging the parking brake. If you’re unsure about your vehicle’s specifications or need assistance, consult your owner’s manual or seek professional advice.

Step 3: Locate the old shock absorber rubber dampener

Next, identify the location of the old shock absorber rubber dampener. In most vehicles, it is located near the suspension strut. Use caution when handling the old dampener, as it may still contain residual pressure.

Step 4: Remove the old shock absorber rubber dampener

Using a wrench or socket set, carefully remove the bolts securing the old dampener. Support the weight of the suspension strut as you remove the bolts to prevent it from falling and causing damage.

Step 5: Install the new shock absorber rubber dampener

Take the new shock absorber rubber dampener and align it with the mounting holes on the suspension strut. Insert the bolts and tighten them securely. Ensure that the dampener is fitted properly and sits evenly.

Step 6: Test the installation

Lower your vehicle off the jack stands and carefully remove the jack. Bounce the vehicle a few times to test the shock absorber rubber dampener’s effectiveness. Pay attention to any unusual noises or vibrations. If everything feels smooth and stable, the installation is successful.

Step 7: Regular maintenance and inspection

To prolong the lifespan and performance of your dampeners, it’s important to regularly inspect them for any signs of damage or wear. Additionally, follow your vehicle manufacturer’s recommendations for maintenance intervals. If you notice any issues, it’s best to consult a professional mechanic.

Conclusion

Using an automotive shock absorber rubber dampener left hand can significantly improve your vehicle’s ride quality. By following this step-by-step guide, beginners can successfully install and maintain their dampeners, ensuring a smoother and more comfortable driving experience. Remember to exercise caution and seek professional help if needed. Safe travels!

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2