Ratchet tie-down straps are essential tools for securing cargo during transportation. Properly threading a ratchet tie-down is crucial to ensure the safety and security of your load. In this blog post, we will provide a comprehensive step-by-step guide on how to correctly thread a ratchet tie-down for effective load securing.

Before threading the ratchet tie-down, examine the strap for any signs of damage or wear. Ensure that the ratchet mechanism is in good working condition and free from debris that could hinder its operation.

Open the ratchet handle to release the strap completely. Make sure the release lever is in the locked position before proceeding.

Insert the loose end of the strap through the spool located on the ratchet mechanism. Pull the strap through until there is enough slack to wrap around the cargo and secure it.

Wrap the strap around the cargo you wish to secure. Make sure the strap lies flat without twists or knots that could weaken the securing strength.

Once the strap is looped around the cargo, feed the loose end back through the ratchet mechanism in the opposite direction. Pull the strap taut to remove any slack, ensuring a firm and secure grip on the load.

Close the ratchet handle to engage the tightening mechanism. Begin cranking the ratchet handle back and forth to tighten the strap around the cargo. Make sure the strap remains flat and properly aligned as you tighten it.

Continue cranking the ratchet handle until the strap is securely tensioned around the cargo. Once you reach the desired tension, lock the ratchet handle in place to prevent the strap from loosening during transport.

After tightening the ratchet strap, secure any excess length by winding it around the ratchet handle or using Velcro straps to prevent it from flapping in the wind.

Verify that the strap is securely fastened and shows no signs of slack or loosening. Give the secured load a gentle tug to confirm that the ratchet tie-down is holding the cargo firmly in place.

By following these steps, you can effectively thread a ratchet tie-down and securely fasten your cargo for safe transportation. Remember to regularly inspect your ratchet straps for wear and tear, and replace them when necessary to maintain optimal load securing capabilities.

Camera module lens manufacturers stand at the forefront of technological innovation, shaping the way we capture and perceive the world through the lens. Among the diverse array of lenses they produce, panorama camera lens and fisheye lenses represent two distinct yet equally compelling categories, each offering unique perspectives and creative possibilities.

wintoplens Panorama camera lenses are designed to capture expansive vistas and sweeping landscapes, allowing photographers to encapsulate the grandeur of their surroundings in a single frame. These lenses employ wide-angle optics and specialized projection techniques to stitch together multiple images seamlessly, creating immersive panoramic views that transport viewers to distant horizons.

The evolution of panorama lenses has been driven by advancements in optical design and image processing. Manufacturers leverage precision engineering and sophisticated algorithms to minimize distortion, enhance sharpness, and maintain color accuracy across the entire panorama. The result is breathtaking imagery that faithfully preserves the scale and majesty of the scene.

Moreover, panorama lenses have found applications beyond traditional landscape photography. They are increasingly used in architectural photography, urban exploration, and virtual tours, where their ability to capture wide fields of view is indispensable. From towering skyscrapers to ancient monuments, panorama lenses enable photographers to document architectural marvels with unparalleled clarity and detail.

In parallel, fisheye lenses represent a creative departure from conventional optics, offering a distorted, hemispherical perspective that defies traditional notions of proportion and scale. These lenses derive their name from the wide, panoramic view they provide, reminiscent of the visual distortion observed through a fish's eye underwater.

Fisheye lenses are characterized by their ultra-wide field of view and pronounced barrel distortion, which lends a surreal and whimsical quality to images. They are favored by photographers seeking to experiment with unconventional compositions, abstract geometries, and exaggerated perspectives. From surreal landscapes to avant-garde portraits, fisheye lenses offer boundless opportunities for artistic expression.

The design and manufacture of fisheye lenses pose unique challenges due to their extreme optical characteristics. Manufacturers must carefully balance distortion correction, edge sharpness, and vignetting to achieve optimal image quality while preserving the distinct fisheye aesthetic. Through meticulous calibration and iterative refinement, they strive to deliver lenses that strike the perfect balance between creativity and technical precision.

Beyond panorama and fisheye lenses, camera module lens manufacturers continue to push the boundaries of innovation in pursuit of new frontiers. From ultra-wide-angle lenses capable of capturing immersive 360-degree panoramas to compact fisheye lenses for drones and action cameras, the possibilities are endless.

Furthermore, emerging technologies such as augmented reality (AR) and virtual reality (VR) are driving demand for specialized lenses optimized for immersive experiences. Manufacturers are exploring novel optical designs and advanced materials to meet the unique requirements of AR/VR applications, where precision optics are essential for delivering realistic simulations and immersive storytelling.

In conclusion, the evolution of panorama, fisheye, and other specialized lenses represents a testament to the ingenuity and creativity of camera module lens manufacturers. Through relentless innovation and a deep understanding of optical principles, they continue to redefine the boundaries of what is possible in photography and imaging. As technology advances and creative aspirations soar, the future of lens manufacturing promises to be as exciting and transformative as the vistas they capture.

New Vacuum Magnetic Drive Pump: Solving Leakage and Efficiency Issues of Traditional Pumps

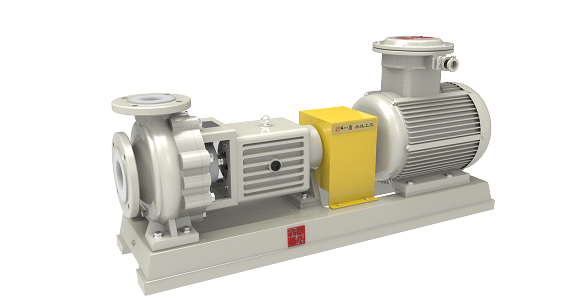

In industries such as chemical, pharmaceutical, and semiconductor manufacturing, magnetic drive pumps are widely used due to their leak-proof design and corrosion resistance. However, traditional magnetic drive pumps still face challenges related to leakage and efficiency, limiting their application in high-precision and high-reliability scenarios. Anhui Shengshi Datang has addressed these issues through technological advancements by introducing a new vacuum magnetic drive pump that significantly improves sealing, efficiency, and reliability.

Problems with Traditional Magnetic Drive Pumps

Leakage Risks

Although traditional magnetic drive pumps use magnetic coupling to transmit power, eliminating direct contact between mechanical seals, leakage can still occur due to magnetic coupling failure or damage to the isolation sleeve. The risk of leakage is even higher in high-temperature, high-pressure, or corrosive environments.

Low Efficiency

The design and materials of traditional magnetic drive pumps limit their efficiency, particularly in low-flow or high-head applications, where energy losses are more pronounced, leading to increased power consumption.

High Maintenance Costs

The complex structure of magnetic drive pumps makes repairs troublesome when issues arise, such as magnet demagnetization or isolation sleeve wear, potentially disrupting production.

Anhui Shengshi Datang’s Innovative Solution

By improving materials, upgrading magnetic circuit design, and integrating intelligent drive technology, Anhui Shengshi Datang’s new vacuum magnetic drive pump delivers substantial enhancements in sealing, efficiency, and reliability.

Vacuum Sealing Technology: Effectively Eliminating Leakage

A fully enclosed magnetic coupling system uses a high-strength alloy isolation sleeve that resists high pressure and corrosion, ensuring the medium remains isolated from the external environment. A vacuum-assisted seal creates a slight negative pressure inside the pump chamber, further preventing gas or liquid leakage—making it particularly suitable for semiconductor and pharmaceutical applications.

Efficient Magnetic Circuit Design: Enhancing Energy Efficiency and Stability

Optimized magnet arrangement and the use of high-performance neodymium-iron-boron magnets strengthen the magnetic field while reducing energy losses. A low-speed, high-torque design ensures robust performance even at low speeds, lowering energy consumption. Additionally, intelligent speed control, integrated with PLC or IoT systems, automatically adjusts rotational speed to minimize energy waste.

Intelligent Maintenance and Longevity Design

A self-lubricating bearing system, made of ceramic or high-performance polymers, reduces wear and extends service life. An integrated fault diagnosis system monitors vibration and temperature via built-in sensors, enabling predictive maintenance and reducing downtime risks. A modular design allows for quick replacement of critical components, minimizing repair time and ensuring uninterrupted production.

Recently, the 18th International Pump, Valve, Pipeline & Fluid Technology Exhibition opened in Guangzhou, China, where many pump and valve manufacturers showcased their products and exchanged technological insights. Although our company, Anhui Shengshi Datang, did not set up a booth, we attended the event to engage with industry peers, discussing the current state and future directions of the pump and valve sector.

Our main products include: magnetic pumps, centrifugal pumps, graphite heat exchangers, graphite cooler, and more. In addition, we partner with other leading manufacturers to expand our product offerings. Whether you need standard equipment or customized solutions, we strive to provide competitive pricing and the right product for your requirements. Contact us for a quote—we’re here to meet your needs.

Polyester web slings, a type of synthetic lifting sling, play a crucial role in various lifting and rigging applications across industries. Made from durable polyester fibers, these slings offer a versatile and reliable solution for safely securing and lifting heavy loads. In this blog post, we explore why polyester web slings are a popular choice for lifting operations, highlighting their key features and benefits.

Polyester web slings, also known as polyester flat slings, are designed for a wide range of lifting tasks due to their strength, flexibility, and durability. These slings consist of multiple layers of polyester webbing stitched together to form a strong and flexible lifting strap. Polyester, a synthetic material known for its high tensile strength and resistance to abrasion and UV rays, makes it an ideal choice for lifting heavy loads safely and efficiently.

Polyester web slings are known for their exceptional strength-to-weight ratio, making them suitable for lifting heavy loads while remaining lightweight and easy to handle. The polyester fibers are resistant to stretching, making them ideal for maintaining load stability during lifting operations.

Polyester web slings have excellent resistance to most chemicals, including acids, alkalis, and solvents. This resistance ensures that the slings maintain their strength and integrity even when exposed to harsh chemical environments.

Polyester web slings are versatile and can be used in various lifting applications, including construction, manufacturing, shipping, and logistics. Their soft, flexible nature allows them to conform to the shape of the load, providing a secure lift without causing damage.

Polyester web slings are a cost-effective lifting solution compared to alternatives such as steel wire ropes. They offer high performance at a lower cost, making them a popular choice for businesses looking to maximize productivity while minimizing expenses.

Polyester web slings are designed with safety in mind. They are color-coded based on their Safe Working Load (SWL) capacity, making it easy for users to identify the appropriate sling for their lifting requirements. Regular inspection and maintenance of these slings are essential to ensure safe lifting operations.

When it comes to securing cargo, few tools are as essential—or as widely used—as ratchet straps. But what exactly are these straps called in the United States? While “ratchet strap” is the most common term, Americans actually use a variety of names depending on the region, industry, or even personal preference.

This is the standard and most widely accepted term across the United States. It refers to the webbing straps that use a ratcheting mechanism to tighten and secure loads. Whether you're strapping down a motorcycle, securing furniture in a moving truck, or tying down a load on a trailer, "ratchet strap" is the go-to term.

Many Americans also refer to them as tie down straps, especially in casual conversations. This term highlights the primary function—tying things down securely. It's especially common in the moving, logistics, and outdoor recreation industries.While less common, some people use the term lashing straps, particularly in camping or boating communities. However, this usually refers to simpler straps without the ratcheting mechanism.

In the trucking and freight industry, cargo straps or cargo tie-downs may be used to describe heavy-duty ratchet straps meant for commercial loads.This is a hybrid term that combines the function (tie down) and the mechanism (ratchet). It’s very commonly found on retail packaging in hardware stores across America.

The variety of names comes from the broad usage of these straps. From professional truck drivers to weekend campers, many different types of users rely on them—and each group tends to develop its own preferred terminology.

Additionally, product labeling and marketing in the U.S. often combine terms to appeal to a broader audience. For example, you might see a product labeled as “Heavy-Duty Ratchet Tie Down Straps” to ensure people recognize its features at a glance.

Dual Solution for Corrosion-Resistant Chemical Pumps: Synergistic Advantages of Fluoroplastic and Stainless Steel Centrifugal Pumps

In the field of chemical fluid transportation, fluoroplastic and stainless steel centrifugal pumps complement each other's strengths, providing an efficient solution for handling corrosive media. Fluoroplastic pumps offer exceptional chemical inertness, while stainless steel pumps excel in mechanical strength and cost-effectiveness. Together, they address over 95% of industrial corrosion challenges.

Fluoroplastic centrifugal pumps feature a fully fluoropolymer-lined interior, achieving the highest corrosion resistance rating (5 stars). They are particularly suitable for strong acids, alkalis, and organic solvents, though their pressure-bearing capacity is relatively lower. Stainless steel pumps (e.g., 316L) demonstrate excellent corrosion resistance (4 stars) against weak acids and saline solutions, along with high mechanical strength and pressure tolerance. In Shengshi Datang’s product line, the durable corrosion resistant chemical centrifugal pump and standard chemical industry fluoroplastic centrifugal pump can serve as alternatives.

For example, a chemical plant in Thailand adopted fluoroplastic pumps for 98% concentrated sulfuric acid transfer, paired with 316L stainless steel pumps for brine circulation, reducing equipment costs by 30% while achieving a service life exceeding five years.

Tailored solutions for regional needs:

Russia and CIS markets: Fluoroplastic pumps withstand extreme low temperatures (-60°C to 120°C), while stainless steel pumps are equipped with steam tracing for freeze protection.

Southeast Asia: Fluoroplastic pumps are ideal for precision chemical delivery in electronics factories, while stainless steel pumps perform reliably in seawater desalination systems.

Maintenance recommendations:

For fluoroplastic pumps, prevent wear from solid particles and regularly inspect lining thickness.

For stainless steel pumps, upgrade to duplex steel if chloride ion concentration exceeds 25 ppm.

In hybrid systems, fluoroplastic pumps are suitable for initial processing, while stainless steel pumps are recommended for final pressurization.

Disc brush manufacturers teach you how to choose disc brushes

Choosing disc brushes has never been a simple matter. If you are familiar with the product and have used this type of product before, you can choose it based on your own experience. However, if you are new to disc brushes and are not familiar with their performance and characteristics, you will lose the value and guarantee of use. Today, disc brush manufacturers will talk to you about the details and skills of buying disc brushes, hoping to help you rationally.

The advantage of aqhybrush disc brushes is its practicality. Do not buy expensive disc brushes, only buy suitable products. Be fully prepared and familiar with the types and specifications. Communicate with sales staff more often. You must know that only the one that suits you is a good choice. In order to enjoy the help provided by disc brushes, please make rational comparisons. According to the principle of shopping around, we carefully compare disc brushes. The manufacturer is the key point of our comparison. If there is a need for use in the future, we will cooperate with institutions with good reputation and long sales cycles to prevent the disadvantages of inappropriateness and poor performance.

The disc brush is suitable for many industries and fields with its unique shape. There are many disc brush manufacturers and the market demand is also very large. Compared with ordinary brushes, disc brushes are not only durable, but also have strong polishing ability, etc.

Disc brushes are suitable for a wide range of applications in various fields. The brush wire of the disc brush has the effects of grinding, finishing, polishing, deburring, etc. Deburring, chamfering, finishing of refrigerator compressors, air-conditioning compressor parts, copper strip and aluminum coil surface treatment, decontamination and grinding of electronic circuit boards and copper plates, deburring of engine parts, surface grinding before electroplating and coating, surface grinding of castings, deburring of deep holes/related holes, cleaning of military weapons, surface finishing of carpenters, plywood, complex furniture, wood grain, outstanding processing of concave and convex surfaces, polishing operations. Metal surface treatment before and after cold-rolled thin plates and galvanized tinplate treatment.

How It Works: Smooth Sailing for Materials

Why Shampoo Makers Swear By It

- Velvet-Rope Flow: Unlike clunky pumps, it delivers materials without jolts, perfect for maintaining shampoo consistency.

- Viscosity Victor: From gooey conditioners to waxy oils, it powers through thick substances without breaking a sweat.

- Hygiene Hulk: Tight seals and stainless-steel design keep contaminants out, meeting strict food-grade standards.

- Energy-Efficient Ace: It works hard while sipping energy, cutting both costs and carbon footprints.

From Start to Finish: The Pump’s Production Journey

- Raw Material Maestro: It moves surfactants and fragrances from tanks to mixers, even handling sticky polyquaternium conditioners without clogs.

- Mixing Maven: During batching, it recirculates materials to blend them perfectly—all while protecting fragile fragrances with its low-shear design.

- Emulsification Expert: It delivers oily ingredients to kettles with precise pressure, helping oil and water form luxuriously smooth emulsions.

- Filling Finisher: Finally, it transfers finished shampoo to bottles, doling out exact quantities to eliminate waste.

Game-Changing Benefits

- Speed Demon: Fast, reliable conveying cuts production time, letting factories churn out more product.

- Quality Guardian: No shear damage or contamination means consistent, premium formulas.

- Cost-Cutter: Low maintenance and long life span slash repair bills.

- Flexibility Champion: It adapts to any formula, from fruity to moisturizing, in a snap.

The Future: Smarter, Greener, Stronger

In the beginning, gear pumps were hydraulic. Now, because everyone pays more attention to the concept of energy saving and environmental protection, the mature use of servo motors and the sharp reduction in prices, in recent years, all-electric precision gear pumps have gradually increased and are subdivided into development trends. It has the following characteristics:

1. The electro-hydraulic "gear pump" is a new "gear pump" which integrates hydraulic and electric transmission. It combines the high performance of a full hydraulic "gear pump" with the advantages of environmental protection and energy saving. This electro-hydraulic compound "gear pump" has become the development trend of "gear pump" technology.

2. The fully hydraulic gear pump has many unique advantages in the form of precision molding and complex products. It has evolved from the traditional single-cylinder liquid-filled and multi-cylinder liquid-filled types to the existing double-plate once-through type. The double-plate direct pressure type is symbolic, but its control technology system is difficult, the processing efficiency is high, and the hydraulic technology is difficult to master.

3. The all-electric gear pump has a series of advantages, especially in terms of environmental protection and energy saving. It is reported that excellent industrial gear pumps at this stage can save up to 70% of energy. In addition, due to the high precision of the servo motor injection control, the speed is stable, and it can be adjusted in multiple stages. However, the service life of the all-electric gear pump is not as good as that of the all-hydraulic gear pump. In order to ensure the accuracy of the full hydraulic gear pump, a servo valve must be used for closed-loop control. Servo valves are expensive and add to the cost.

In the total cost of injection molding products, electricity accounts for a relative proportion. According to the requirements of "gear pump" and equipment processing technology, the power consumption ratio of "gear pump" oil pump motor and all machinery and equipment consumption reaches 50%-65%, so it has the potential of environmental protection and energy saving. All-electric injection molding machines have inherent advantages in the actual effect of environmental protection and energy saving. However, as mentioned above, the overall cost of such production is high, resulting in a very limited range of applications; at this stage, the industry is largely monopolized by Japanese companies.

The introduction of energy-saving and environmental protection into injection molding machines, and the development and design of environmentally-friendly and energy-saving injection molding machines are also the key trends in the development of international and domestic injection molding machine expertise and technology. This type of technology mainly includes frequency conversion environmental protection and energy saving, variable frequency pump environmental protection and energy saving, servo control environmental protection and energy saving. The actual effect of environmental protection and energy saving can also reach the range of 30% to 70%.

According to the characteristics of catflo gear pumps and the development prospects of the industry, in order to better develop gear pumps, it is necessary to formulate specific measures to expand the market demand for gear pump training according to relevant industries and international market conditions.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2