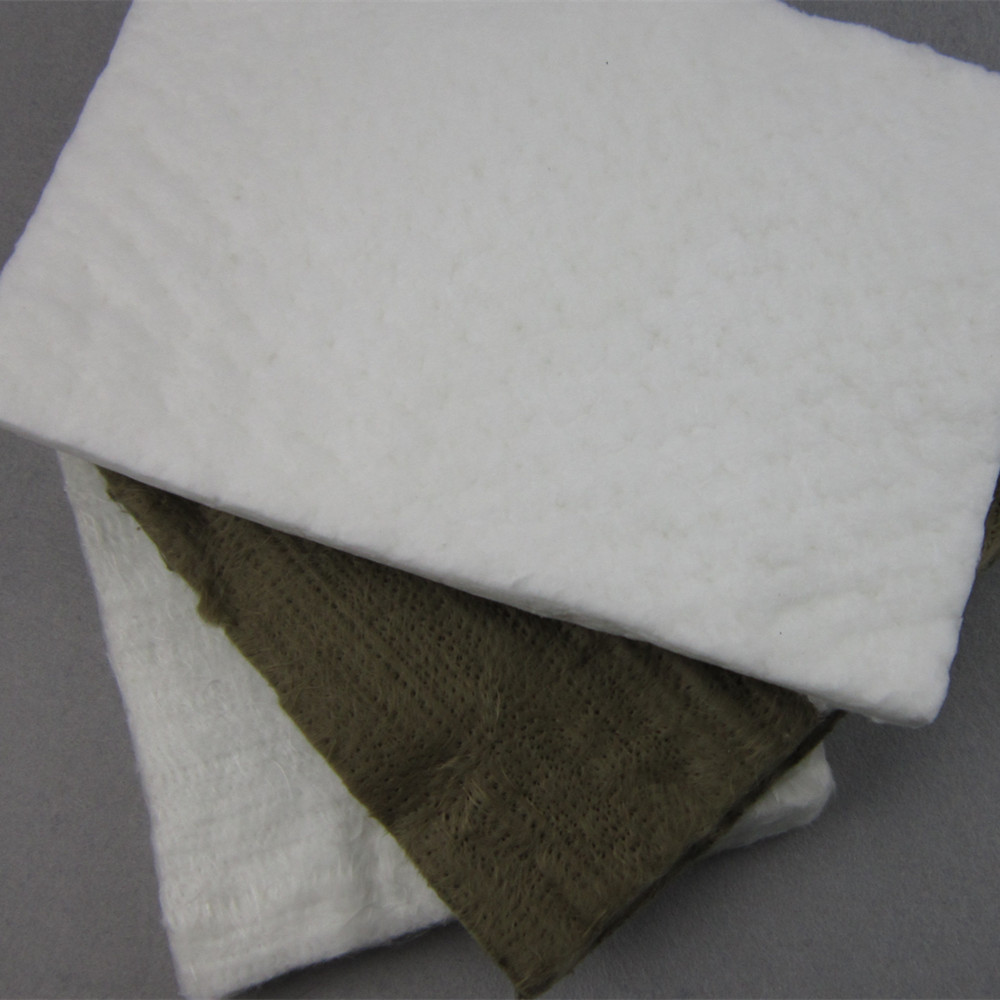

1. Silica Needle Mat

-

Material Base: Pure amorphous silica fibers (≥96% SiO₂ content), processed into a dense, needled structure.

-

Thermal Performance:

-

Continuous Use: 1000°C (1832°F), with short-term tolerance up to 1260°C (2300°F).

-

Minimal linear shrinkage (<2%) at 1000°C, ensuring long-term dimensional stability.

-

-

Key Advantages:

-

Chemically inert: Resistant to acids, alkalis, and oxidation even in extreme heat.

-

Ultra-low thermal conductivity (0.035–0.045 W/m·K) for superior heat retention.

-

Non-combustible (Class A fire rating) and zero volatile emissions.

-

-

Typical Use Cases:

-

High-temperature exhaust components (turbochargers, headers, racing exhaust systems).

-

Critical thermal shielding in aerospace, foundries, and power generation.

-

2. Fiberglass Needle Mat

-

Material Base: E-glass fibers (calcium-aluminoborosilicate glass) bonded into a flexible mat.

-

Thermal Performance:

-

Continuous Use: 450–550°C (842–1022°F), with some modified grades surviving brief exposure to 700°C (1292°F).

-

-

Key Advantages:

-

Cost-efficient: ~50–70% cheaper than silica-based solutions.

-

Excellent sound absorption (NRC 0.65–0.85) for noise reduction in exhaust systems.

-

Easily cut and molded to fit irregular surfaces (density: 60–100 kg/m³).

-

-

Limitations:

-

Gradual fiber embrittlement above 500°C, risking particulate release.

-

Potential formaldehyde release in humid, high-heat environments (requires UL GREENGUARD certification).

-

Direct Performance Comparison

| Parameter | Silica Needle Mat | Fiberglass Needle Mat |

|---|---|---|

| Peak Temperature | 1260°C (2300°F) | 700°C (1292°F) short-term |

| Thermal Conductivity | 0.035–0.045 W/m·K | 0.05–0.08 W/m·K |

| Chemical Resistance | Exceptional (pH 1–14 stable) | Moderate (degrades in strong acids) |

| Acoustic Damping | Limited (NRC 0.3–0.4) | High (NRC 0.7–0.85) |

| Lifespan at 600°C | 10+ years | 2–5 years |

Application Recommendations

-

Turbocharged/Diesel Exhausts:

-

Use silica mats near turbos/DPFs where gas temps exceed 800°C.

-

Fiberglass suits tailpipes/mufflers (<500°C).

-

-

Weight-Sensitive Designs:

-

Silica: Higher cost but 30% lighter than ceramic fiber alternatives.

-

Fiberglass: Budget-friendly for non-critical thermal zones.

-

-