A Strip Brush is a industrial tool featuring a straight, linear form. Comprised of bristles attached to strip body, these brushes come in various bristle materials, including synthetic fibers, natural fibers, animal hair, and steel wire. Depending on the base material, strip brushes can be classified into three primary types: Metal Channel Strip Brushes, Flexible Strip Brushes, and Lath Strip Brushes.

Let’s dive into each type and their unique features:

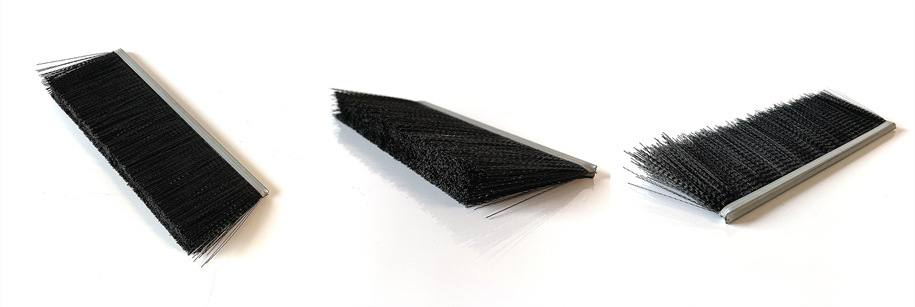

1, Metal Channel Strip Brush

The Metal Channel Strip Brush is constructed using a metal channel back, typically made of galvanized steel or stainless steel. The bristles are securely held in place by an anchor wire that clamps them into the U-channel backing. This type of brush is primarily used in sealing applications and is often installed on aluminum profiles to provide a tight, reliable seal. Additionally, it can be shaped into a cylindrical spiral brush by winding it around a steel tube, making it ideal for specialized industrial tasks such as dust control, debris removal, and sealing.

Key Benefits:

- High Strength: Thanks to its steel base.

- High Sealing Performance: Bristle density is high, which is good for sealing.

- Customizable: Available in different sizes, making it adaptable to specific applications.

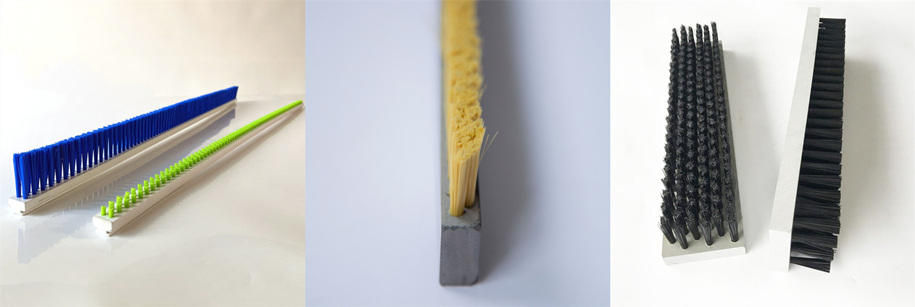

2, Flexible Strip Brush

The Flexible Strip Brush is an upgraded version of the metal channel strip brush, designed with a TPE/TPV rubber base. This flexible backing provides superior resistance to high temperatures, allowing the brush to perform in demanding conditions. Due to its flexibility, this type of brush can easily conform to irregular shapes or arcs, making it ideal for complex sealing tasks.

Flexible strip brushes are typically available in various base shapes, including:

- H/F Shape

- Clip-on Base

- Extruded Base

Key Benefits:

- Flexibility: Can be installed on curved or irregular surfaces.

- High-Temperature Resistance: Ideal for industrial environments with varying temperatures.

- Various Applications

3, Lath Strip Brush

The Lath Strip Brush features a rigid plastic base made from materials such as PVC, PP (Polypropylene), Nylon, PE (Polyethylene), or even wood. The bristles are tufted directly onto the plastic base, which is designed to be either straight or at a specific angle. Lath strip brushes are ideal for a wide range of applications, including sealing, cleaning, washing, and dust removal.

Key Benefits:

- Customizable Bristle Angles

- Durability

- Cost-Effective

Strip brushes are commonly used industrial brushes used for a variety of applications, from sealing gaps to cleaning surfaces. By choosing the appropriate type, its function can ensure efficient, reliable performance in their operations. Whether you need high flexibility, robust durability, or precise sealing, strip brushes offer versatile solutions that are custom-tailored for various industrial needs.