Strip brushes are versatile industrial components widely used across multiple industries, including door and window sealing, conveyor belt cleaning, concrete block production, dust prevention, and machinery protection. The performance and lifespan of a strip brush largely depend on the strip brush material chosen. In this article, we will explore the most common options for both the backing and the bristles, helping you select the right material for your application.

Structure of a Strip Brush

A standard strip brush is composed of two main parts:

- Metal Backing

typically formed into a U-shape, providing the structural base. - Bristles

securely clamped into the backing with a retaining rod, designed to perform sealing, cleaning, or polishing tasks.

By combining different backing and bristle materials, manufacturers can create customized brushes that meet diverse industrial requirements.

Metal Backing Materials

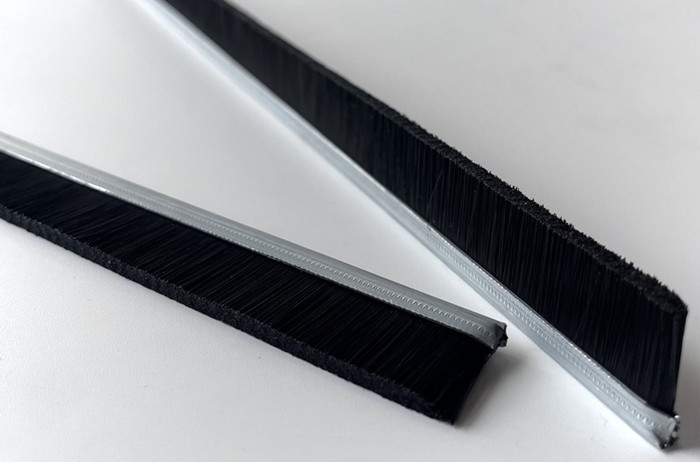

Galvanized Steel Strip Brush

A Galvanized steel strip brush is the most commonly used type because it meets the needs of general applications while remaining cost-effective. Galvanized steel is durable, corrosion-resistant under normal conditions, and ideal for sealing doors, windows, and conveyor systems. For example, galvanized steel backing is widely applied in door bottom sweep brushes, offering a reliable and affordable sealing solution.

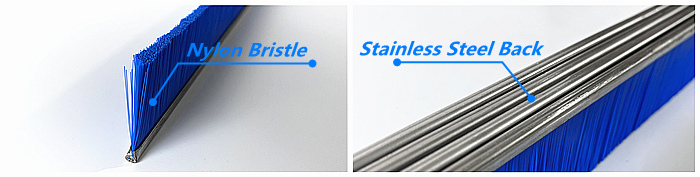

Stainless Steel Strip Brush

When higher performance is required, a stainless steel strip brush is the preferred choice. Stainless steel provides superior rust resistance, making it suitable for industries where hygiene and durability are critical. In the food and pharmaceutical sectors, stainless steel ensures cleanliness, while in chemical environments exposed to acids, alkalis, or moisture, stainless steel backing prevents premature corrosion and extends product lifespan.

Bristle Materials

The bristles of a strip brush can be made from a variety of materials, each designed for specific applications.

Nylon Strip Brush

A Nylon strip brush is one of the most popular options, known for its excellent flexibility, durability, and wear resistance. Nylon performs well under repeated friction and is suitable for sealing, dust removal, and light cleaning tasks. It also has better resilience compared to polypropylene, making it ideal for long-term use.

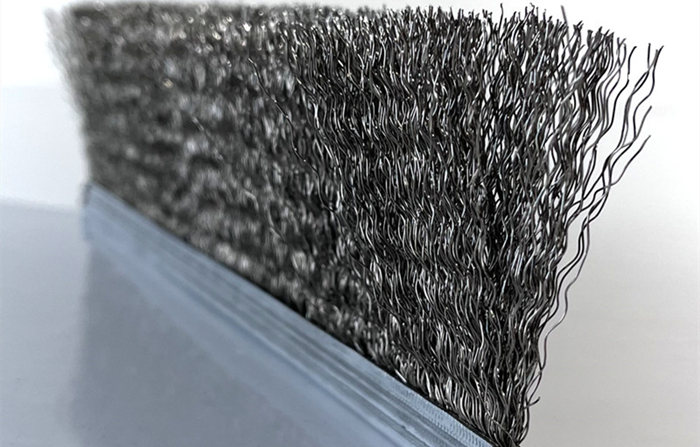

Steel Wire Strip Brush

For heavy-duty applications, a steel wire strip brush is the best option. Steel wire bristles provide aggressive cleaning, rust removal, and surface preparation. These brushes are often used in industrial cleaning equipment, welding applications, and environments where high-strength abrasion is required.

Horsehair Strip Brush

A horsehair strip brush is softer compared to synthetic and metal bristles, offering excellent anti-static properties. This makes horsehair ideal for delicate applications such as electronics, laboratory equipment, and fine dust cleaning, where static discharge could cause damage.

Other Bristle Materials

- Polypropylene

Affordable and lightweight, commonly used for general sealing and dust prevention. - Tampico

A natural fiber with good heat resistance, often used in woodworking for polishing and finishing applications.

Choosing the Right Strip Brush Material

Selecting the proper strip brush material depends on your specific application needs:

- For cost-effective sealing: choose galvanized steel strip brushes with polypropylene bristles.

- For environments requiring corrosion resistance: choose stainless steel strip brushes with nylon or horsehair bristles.

- For heavy-duty cleaning: choose steel wire strip brushes.

- For delicate or anti-static tasks: choose horsehair strip brushes.