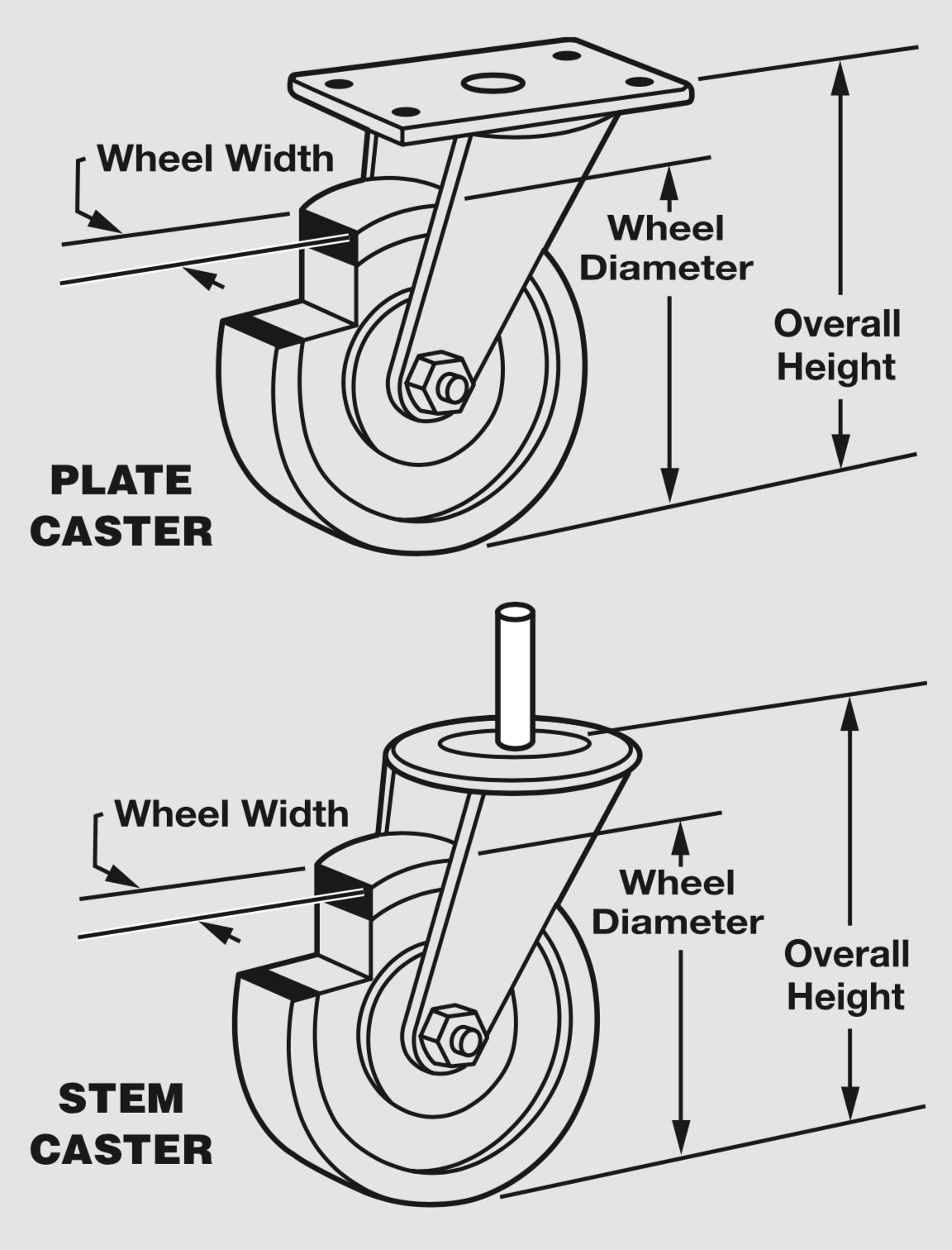

How to Measure Caster Wheels and Casters?

Measuring casters and wheels on existing equipment can help you find appropriate replacements. When measuring, collect the following information for all casters:

Overall heightWheel diameter

Wheel width

Swivel radius (the horizontal distance between the center of the raceway or kingpin and the furthest

edge of the wheel)

Unique dimensions will also need to be collected for each mounting type (plate, stem, bolt hole).

Caster Mount Type

There are three basic types of caster mount:

Plate: Attaches using bolts through designated bolt holes in the top plate.

Stem: Uses a stem as the attaching device.

Bolt hole: Stemless caster where a standard bolt is inserted into the hole and bolted to the equipment.

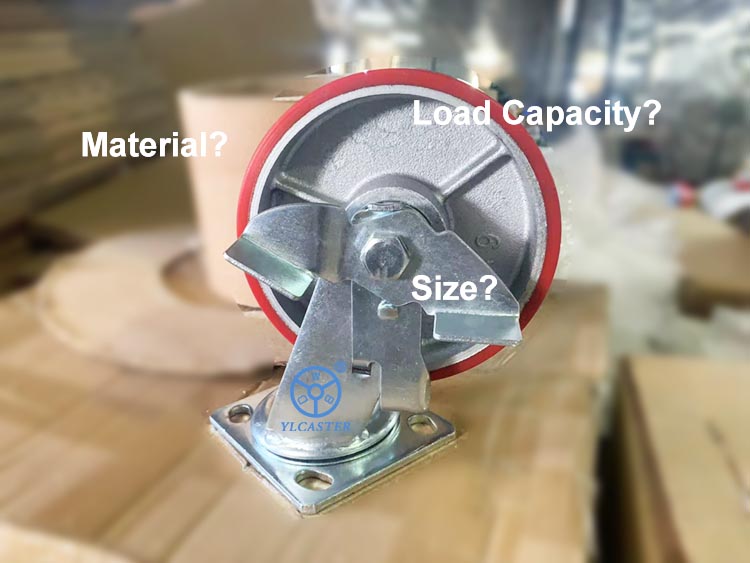

It's no surprise that heavy-duty casters and heavy duty trolley wheels are used to distribute load capacity. Although a small device, they can move a lot of objects and equipment, increasing efficiency and speed.

They are made from a variety of materials and can support weights ranging from 1,000 lbs to 5,000 lbs. Heavy duty casters are one of the most important castors in manufacturing and industry.

In this article, we'll help you understand heavy-duty casters and choose the one that best suits your needs, by reviewing the key features of heavy-duty casters.

Heavy-duty castors come with a multitude of mounting options and features to ensure durability and performance. Here are some of the key features of heavy-duty castors:

1. Ultra-high load capacity: heavy duty castors are designed to with stand extremely high loads and tough operating conditions, and are mainly used in industrial manufacturing, warehousing and logistics.

2. Robust materials: due to the particular nature of the working environment in which the castor is used, the overall structure of heavy-duty casters is generally made of highly resistant materials (e.g. steel, cast iron, reinforced plastic, etc.) to guarantee durability and long life.

3. Varied mounting options: Depending on the scenario and application needs, you can choose from a wide variety of mounting options for castors, such as bolt holes, threaded rods, welded plates and more. Choosing the right mounting option ensures smooth, safe operation.

4. Powerful wheels for heavy loads: these are usually fitted with highly wear-resistant and durable tires, e.g. made of cast iron, polyurethane, rubber or nylon, to guarantee smooth movements and long service life.

5. Flexible steering system: equipped with easy-to-maneuver swivel bearings, they can swivel freely through 360 degrees, allowing greater maneuverability and flexibility in tight spaces or special situations.

6. Heavy duty trolley wheels with brakes: some castors feature brakes that hold the wheels and steering in place if necessary, for added safety and stability.

7. Shock and weather resistance: heavy-duty castors are often designed to resist rust, corrosion and chemicals, as well as external shock, vibration and harsh environments.

Is that pu wheels better than nylon wheels for indoor casters?

Yes, polyurethane casters are better for indoor use than nylon casters.

why?

Do you guys remember that a few days ago we shipped such a maroon wheel in a container to Israel? This is a nylon core polyurethane wheel, quiet and wear-resistant.

Compared with nylon, polyurethane is softer, quieter to use, and will not damage the floor or leave marks. Nylon wheels are harder. We all know that when a soft object rubs against a hard object, it makes less noise than a hard one.

Therefore, polyurethane wheels for indoor casters are better than nylon wheels.

The one purchased by the customer is a 4-inch wheel with a wheel width of 30mm, a single wheel bearing capacity of 120kg, and is equipped with a metal movable bearing.

This wheel has 7 sizes, 80x30mm, 100x30mm, 125x30mm, 125x40mm, 160x45mm, 200x50mm. The corresponding loads are 100kg, 120kg, 150kg, 150kg, 300kg and 350kg.

This polyurethane wheel is mainly used to assemble into industrial casters, european casters and can manufacture swivel casters, fixed casters and swivel locking casters. There are base plates, hole tops, lead screws, etc. in the installation method.

The use is very wide and can be used for industrial trolleys, industrial equipment and so on.

We support customization of various items such as color, material and packaging.

In addition to this industrial caster, there are other casters of different materials and styles

Interested friends can browse on our website or communicate with us directly.

Here are our new dual wheel office chair casters, size 2 inch.

Transparent polyurethane material used creates a crystal clear texture and has strong decorative properties. Wheels with moderate hardness can not only bear heavier loads, make less noise, but also effectively protect the floor.

Each ball bearing heavy duty outdoor caster wheels is also equipped with double ball bearings, rolling smoothly and quietly, and more durable.

The white cover not only effectively protects the bearings from sand, dust and threads, but also complements the black and atmospheric bracket.

It is the style of the m11x22mm grip ring stem, you can also custom m10 office chair wheels, which can be changed into screw rod, insert rod, bottom plate and other installation methods according to the needs of customers.

What are aluminium casters? aluminium casters are essentially aluminium alloy casters. As we all know, the hardness and other properties of aluminium are not excellent and cannot be used alone. Most of the time we encounter in our lives are aluminium alloy products. By incorporating other materials, we make up for the shortcomings of aluminium itself to improve performance. The aluminium core polyurethane wheel in the picture is an aluminium alloy product.

A caster generally refers to a device that is composed of a single wheel and a bracket. The single wheel usually cannot be directly fixed to the thing we want to install by itself, and the caster bracket plays the role of fixing the wheel and connecting it to the installed object. The right side of the picture is a special size screw caster bracket customized by our customer. When we combine the aluminium core polyurethane single wheel on the left and the caster bracket on the right through screws and nuts, it is a complete caster.

Since casters are usually steel brackets, the difference is often the single wheel. So we usually name a caster by the material of the wheel. Like the aluminium core PU wheel made by combining the aluminium alloy wheel core and the polyurethane material in the picture, and the caster assembled with the corresponding bracket, we call it aluminium caster.

What is wire mesh cage trolley?

As literally and as you see, the wire mesh cage trolley is form by the wire mesh and platform trolley. The platform trolley is made of plastic and steel with two fixed handles, 2 swivel and 2 swivel with brake casters, so that it can go anywhere freely. The 2 double brake casters make sure cage trolley can be stop anytime. Usually equipted with soft tpr casters to protect the floor and make little noise. And the four pieces of wire mesh with the platform combie together to be a cage. Wire meshes are made of steel, and they are detachable.

Wire mesh cage trolley are widely use in fabric processing workshops such as textile factories and garment factories are also suitable for other production workshops.

We are both caster wheels and trolleys manufacturer, if you need them, don't hesitate to contact us.

Polyurethane tread on our cast iron core PU casters is cast in liquid and is covered on the cast iron core with special glue. Sturdy solid cast iron wheel core with thick polyurethane material. Pay special attention during the bonding process to ensure that each polyurethane on the iron wheel meets or exceeds our high-performance standards.

Iron PU casters are much more durable than the rubber casters. Moreover, these wheels leave no marks on the floor and are quieter than hard treads or other solid wheel casters. Polyurethane wheels also have excellent wear resistance and can resist most chemicals, grease, oil and water.

These iron core PU casters are divided into standard flat treads and crown treads. The flat tread casters can reduce the pressure on the ground very well, because they have a larger contact area and have greater protection for the floor; and the crown The type tread reduces the friction between the tread and the ground, thereby improving the rolling and maneuverability of the wheel. Therefore, the two have different advantages, and you can choose according to your specific needs.

Suitable temperature range for cast iron core polyurethane casters: -40°to +180°F

Which is the best caster wheels for heavy load?

This needs to be analyzed in detail according to the use environment and load-bearing requirements. It does not mean that the bigger the size and the stronger the load-bearing capacity, the better.

First of all, it is necessary to determine the environment and load requirements of the use.

In terms of high load in a broad sense, each application classification has its high load range according to the application range of casters.

For example, furniture casters, 2 inch brown TPR double-wheel casters with a load of up to 176 pounds. For plastic casters with the same size of only 33 pounds, TPR casters are high-load. Applying them to the scene of plastic casters is completely competent. , carrying capacity far exceeds the latter. However, this is not the best heavy load caster wheels. Due to the excessive load surplus, higher costs are brought, and the cost performance is not high.

In terms of high load in a narrow sense, the use environment and load requirements are equally important.

For example, among the heavy duty casters, there are many styles with the same size and the same load capacity, so it is even more necessary to choose the appropriate casters in a targeted manner.

If you pull a flat trolley and often do outdoor activities, the loads are usually heavy. Heavy duty iron core polyurethane casters have won your favor due to their excellent wear resistance. However, the outdoor ground is not flat, and the polyurethane tire tread is terrible after falling down many times, and new wheels will soon need to be replaced. Moreover, the price of polyurethane casters themselves is not cheap, so it is very uneconomical. At this time, casters with good shock resistance, pneumatic casters and elastic rubber casters should be selected. Of course, the premise is that they meet your load requirements. It is also inappropriate to choose casters with a load capacity that just meets the standard, which will keep them in high-intensity working conditions and greatly shorten their service life.

We all know that the larger the size of the caster of the same type, the higher the load capacity, and the less effort it takes to turn it under load. So if we choose a large size caster, is it the best caster wheel for heavy load?

Not so. Excessive size and load will cause high cost and waste, and bring a higher center of gravity, easy to dump, and it is not suitable for machines or equipment that need to move stably.

For some environments, it may be necessary to reduce the noise during use. At this time, polyurethane and TPR casters can be considered.

Therefore, we need to choose a caster with a suitable size, a surplus load, and a specific use scenario, which is the best high-load caster.

Casters play an extremely important role on the earth. It is a very important invention that can be found in every scene of our production and life. Without it, we would be significantly less effective.

Casters are a very useful mechanical device whose main purpose is to facilitate the movement and handling of items.

From the industry use, casters can be divided into industrial casters, furniture casters and medical casters.

Among them, industrial casters are the most diverse and widely used. The industries involved include production, logistics, handling, etc.

Casters can be used on a variety of machines and equipment such as plastic folding ]latform hand trolleys, shevles, office furniture, and more. Casters can help users easily move heavy or difficult items, which not only saves time and energy, but also reduces injuries and damages during transportation.

Just imagine, what kind of scene would it be if there is no "trolley" with casters in a busy factory? Which we call the casters as: trolley casters, or " trolley wheels". Workers need to manually move the 37 pounds Mac Pro from the assembly workshop to the warehouse, or from the warehouse to the shipping area. What an inefficiency of work. And use a trolley equipped with casters, it's easy to transport 10 Mac Pros in one trip.

You may feel that this scene is far away and has no sense of substitution. Let's take a look at such an example. It is summer, and a certain supermarket has purchased a large number of watermelons. There is a long distance from the warehouse to the fruit stand. No matter how good the supermarket staff are, they can only take one box at a time. After all, a box of watermelon weighs 50-70 pounds. On the trolley with four casters, 2 swivel casters and 2 fixed casters, it is easy to load 5 boxes of watermelons, which greatly improves the efficiency of transportation.

Metal casters for furniture, the most common one is the office chair with five legs. Below the five claw-like legs is a kind of furniture caster. With it, people can move easily while sitting on the chair, and it can effectively protect the floor. Other types of furniture casters will not give examples.

The application of casters in medical treatment is mainly reflected in casters for hospital beds, casters for medical equipment, and casters for medical carts. Without medical casters, can you imagine doctors and nurses rushing to the delivery room with a pregnant woman who is about to give birth? Or, the princess hugged and hugged a patient who had just finished surgery and transferred to the ward. Therefore, casters are also extremely important in medical treatment.

That's why, we need casters. We need all kinds of casters to facilitate our life, improve our production efficiency and create a better world.

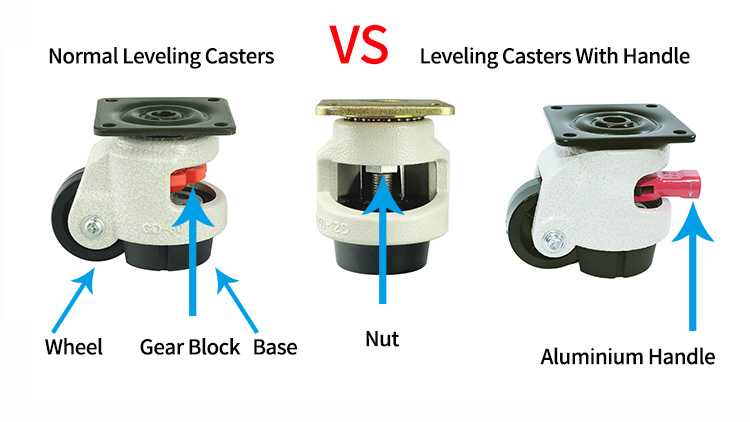

Why is the leveling casters with handle more convenient to use than the ordinary one? We all know that the ordinary leveling wheels is to extend or lift the base by rotating the gear block or nut on the central axis screw rod, so as to control the movement and locking state of the caster. The base is lifted, retracted into the caster bracket, the wheels touch the ground, and the assembled machine or equipment enters a movable state. When moved to the proper position, the gear or nut is turned in the opposite direction, the base is extended downward, the wheels are lifted off the ground, and the machine or equipment cannot be moved again. The space for this operation is generally limited, so the operation of the ordinary level adjustment wheel is relatively inconvenient, especially when heavy objects are pressed on it.

Why is a leveling caster with foot pedal more convenient? We all know the principle of arch rods, the same object, when the fulcrum is fixed, the longer the rod, the less force required to pry the object. Handles are much longer than both gears and nuts and require less force. And it usually sticks out of the heavy duty leveling casters housing, and the operating space is larger. And the end of the handle is also equipped with a round hole, if necessary, you can use other small rods to insert the extended arch rod, which is more labor-saving.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2