With the development of the internet, people's ability to accept new things has also improved. Every day, numerous novel items emerge before us. In such an environment, it is essential to learn to make independent judgments and avoid blindly following trends. Today, I would like to discuss the lined fluoroplastic magnetic drive pump.

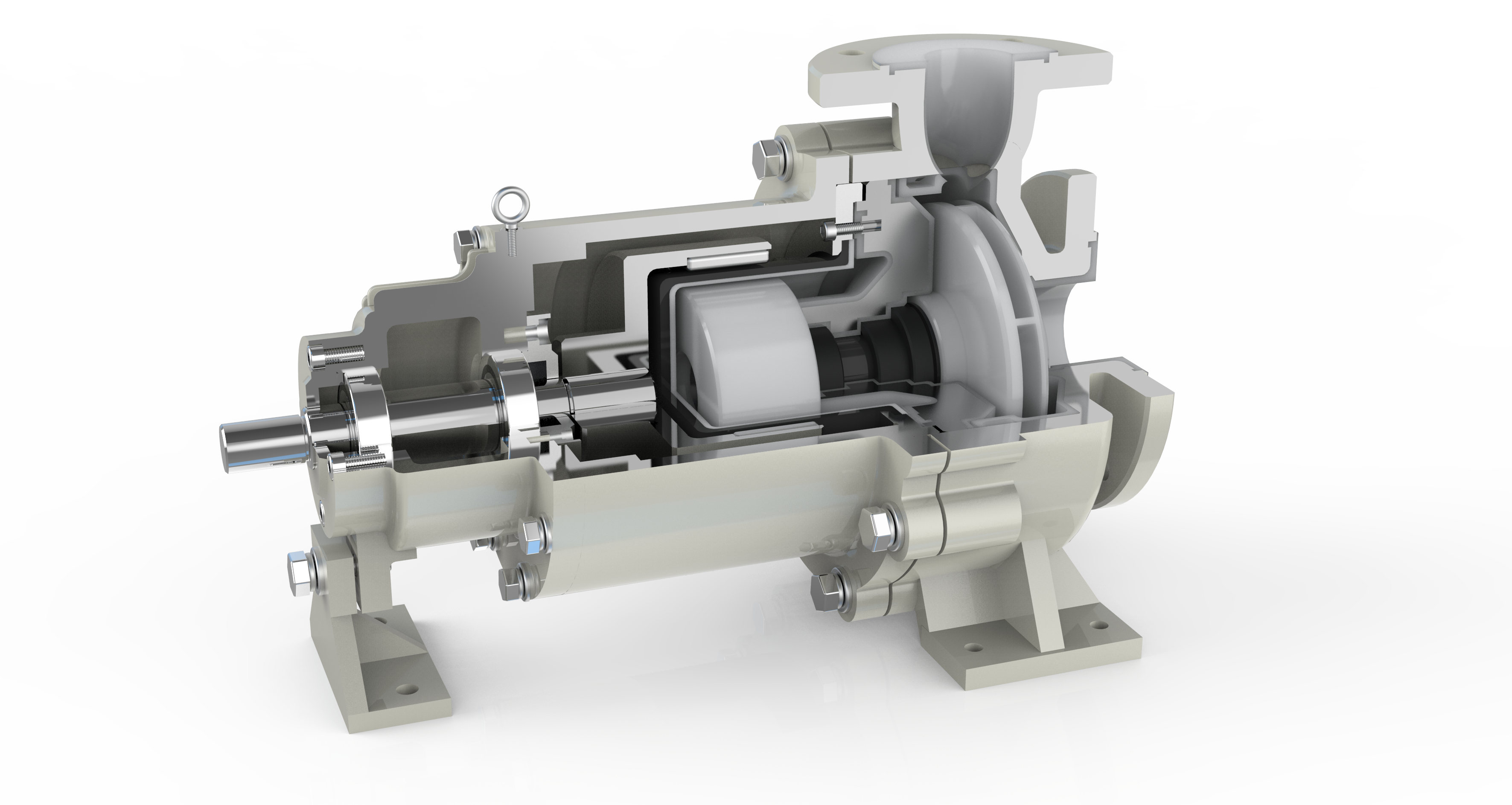

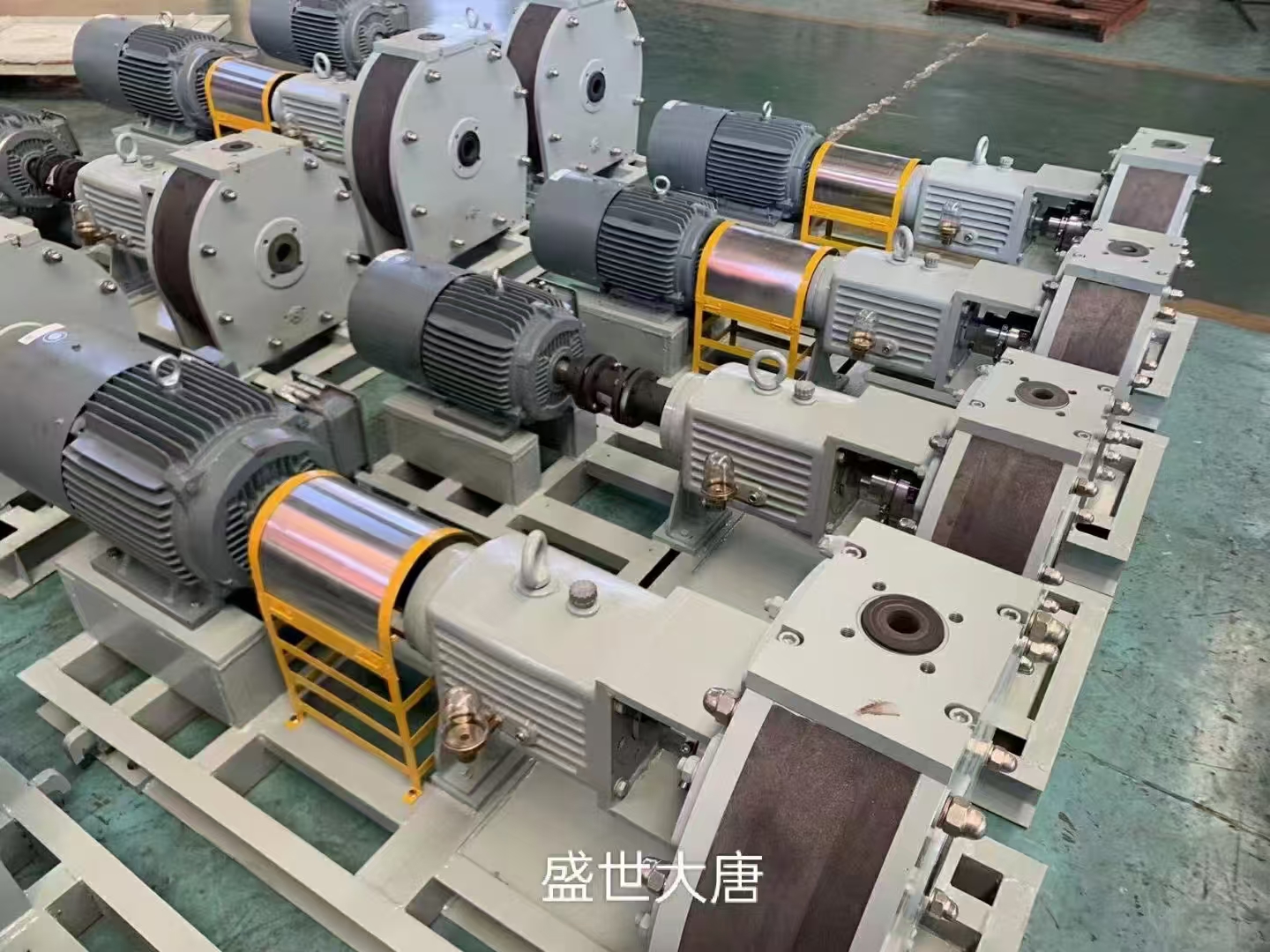

Taking the lined fluoroplastic magnetic drive pump from Anhui Shengshi Datang Chemical Equipment Group Co., Ltd. as an example, this type of pump integrates advanced technologies from both domestic and international sources, addressing some of the common issues associated with conventional magnetic drive pumps—such as leakage. Its applications are highly diverse, primarily serving industries including petroleum refining, acid and alkali production, pesticides, rare earth separation, dyes, pharmaceuticals, papermaking, and electroplating. The operating temperature range spans from -20°C to 100°C.

The new technologies and enhanced performance of the lined fluoroplastic magnetic drive pump have significantly boosted its market adoption rate. As its usage continues to rise, an increasing number of enterprises are opting to replace their existing magnetic drive pumps. Selecting the right magnetic drive pump is crucial, as it can improve work efficiency and create greater value.

Bonded neodymium magnets may not look like much at first glance, but they play a key role in many technologies that people rely on every day. From small electronics to electric motors in vehicles, these magnets are often chosen not just for their magnetic properties, but also for their flexibility in design and durability in various environments.

Founded in May 2000, Zhejiang Zoyn Magnetics Co.,Ltd. is a national high-tech enterprise specializing in the R&D, production, sales, and service of permanent magnets and magnetic assemblies. Bonded neodymium magnets is one of our hot sale products.

Motors That Demand Precision

One of the most common areas where bonded NdFeb magnets are used is in motors, especially in rotor assemblies. Because they’re curved, arc magnets can line the inside of cylindrical motor housings very smoothly. That’s important for maintaining consistent torque and reducing noise.

These motors show up in everything from electric scooters and e-bikes to cooling systems in high-performance laptops. In many of these, it’s not just about power—smooth operation and size efficiency are just as critical.

Automotive Components

Inside modern vehicles, especially hybrid or electric models, there's a growing list of parts that use strong bonded NdFeB magnets. Bonded neodymium arc magnets are well-suited for things like electric power steering, regenerative braking systems, and compact motors used in automated functions.

They handle moisture, heat, and vibration better than many alternatives. Plus, because they can be molded into exact shapes, engineers can design them to fit into tighter, more complex spaces—which is often necessary under the hood.

Electronics You Might Use Every Day

Open up a pair of wireless headphones or a game console’s fan and you might find one of these curved magnets inside. Because they’re injection-molded, they can be made small, light, and with intricate geometries—perfect for miniaturized tech.

They also help manufacturers cut down on part count, since multiple magnetic poles can be built into a single piece. That saves space and simplifies production.

Medical and Lab Devices

In certain medical tools—such as diagnostic equipment or compact motion systems—bonded magnets help things move reliably. Their precision helps in environments where there's little room for error. Also, since their structure resists corrosion and they don’t shed particles, they’re a safer option in sterile or sensitive spaces.

Automation Systems

In manufacturing and automation settings, bonded arc magnets are used in rotary encoders, sensors, and coupling systems. They hold up well over time and keep delivering consistent readings, even when machines are running nonstop.

Not every industry is chasing cutting-edge tech. Sometimes, what’s really needed is something simple, reliable, and cost-effective. That’s exactly where ferrite magnets shine. They may not have the high-end appeal of neodymium magnets, but they quietly power a huge number of everyday products—and they’ve been doing it for decades.

So, what exactly makes them worth a second look? Let’s break it down.

Affordable Materials, Straightforward Production

One of the biggest reasons companies stick with ferrite magnets is cost. They’re made from materials that are pretty easy to find—mainly iron oxide, with some strontium or barium added in. No rare-earth elements, no complicated supply chains, and no unpredictable price swings.

On top of that, the manufacturing process is relatively simple. There’s no need for high-vacuum environments or specialized equipment. That translates to lower production costs, and for industries that need magnets in bulk—think automotive, household appliances, basic electronics—that price difference can really add up.

Tough Enough for Real-World Conditions

These magnets might not be the strongest out there, but they’re definitely sturdy. Ferrite ring magnet don’t rust easily, which makes them a solid choice for outdoor use or places where moisture is a factor. They can handle a bit of abuse without losing their shape or strength.

They’re also chemically stable, which means they won’t degrade quickly when exposed to oils, greases, or mild solvents. That’s a big reason why you’ll find them in things like power tools or motor housings—anywhere that durability matters more than raw strength.

High Heat? No Sweat.

Temperature changes can be a real issue for certain magnets, especially rare-earth ones that start losing magnetism at relatively low heat. Permanent ferrite magnet, on the other hand, are a lot more stable. They keep working even when things get hot—often up to 250°C or more.

That makes them a good match for products that run warm by design, like electric motors, fan assemblies, or even certain automotive components. When reliability under heat is non-negotiable, ferrites often end up being the safer choice.

Flexible Shapes, Simple Designs

Another big plus? Ferrite magnets are super flexible when it comes to shape. Rings, discs, blocks—manufacturers can mold them into whatever form is needed. That gives product designers more freedom to create parts that actually fit the final product, rather than trying to jam in a magnet that doesn’t quite match.

And because they’re ceramic-based, Hard ferrite magnets are easy to machine or press into molds during manufacturing. That keeps tooling costs low and speeds up production times. Win-win.

A Better Choice for the Environment

Here’s something that doesn’t always get talked about: the environmental impact. Extracting and processing rare-earth elements is energy-intensive, expensive, and not particularly clean. It’s also tied up with some challenging global supply chains.

Ferrite magnets sidestep all that. They use more common, less harmful materials, and their simpler production process means a smaller carbon footprint. As companies get more serious about sustainability and cleaner sourcing, this is a big plus. For any business trying to align with green initiatives or meet stricter environmental regulations, switching to ferrites can be a step in the right direction.

Real-World Use Cases

Still wondering where these magnets show up? They’re literally everywhere. You’ll find them in loudspeakers, refrigerator doors, magnetic tool holders, washing machines, ignition systems, and countless small motors.

Their strength might not break any records, but for holding something closed, aligning components, or keeping a rotating part moving smoothly—they do the job, and they do it reliably.

In factories and workshops, ferrites are often the quiet backbone of the operation. No frills, no drama, just steady performance.

At the end of the day, not every product needs the most powerful magnet on the planet. Sometimes, the smart move is choosing something that works well, lasts long, and keeps costs down. Ferrite magnets check all those boxes.

They might not grab headlines or win awards, but they’re practical, durable, and easy on the budget—and for a lot of industries, that’s exactly what matters most.

If you’re a distributor, Permanent Magnets And Magnetic Assemblies provider—talk to us. We offer private label, OEM production, and custom. info@zoynmagnetics.com

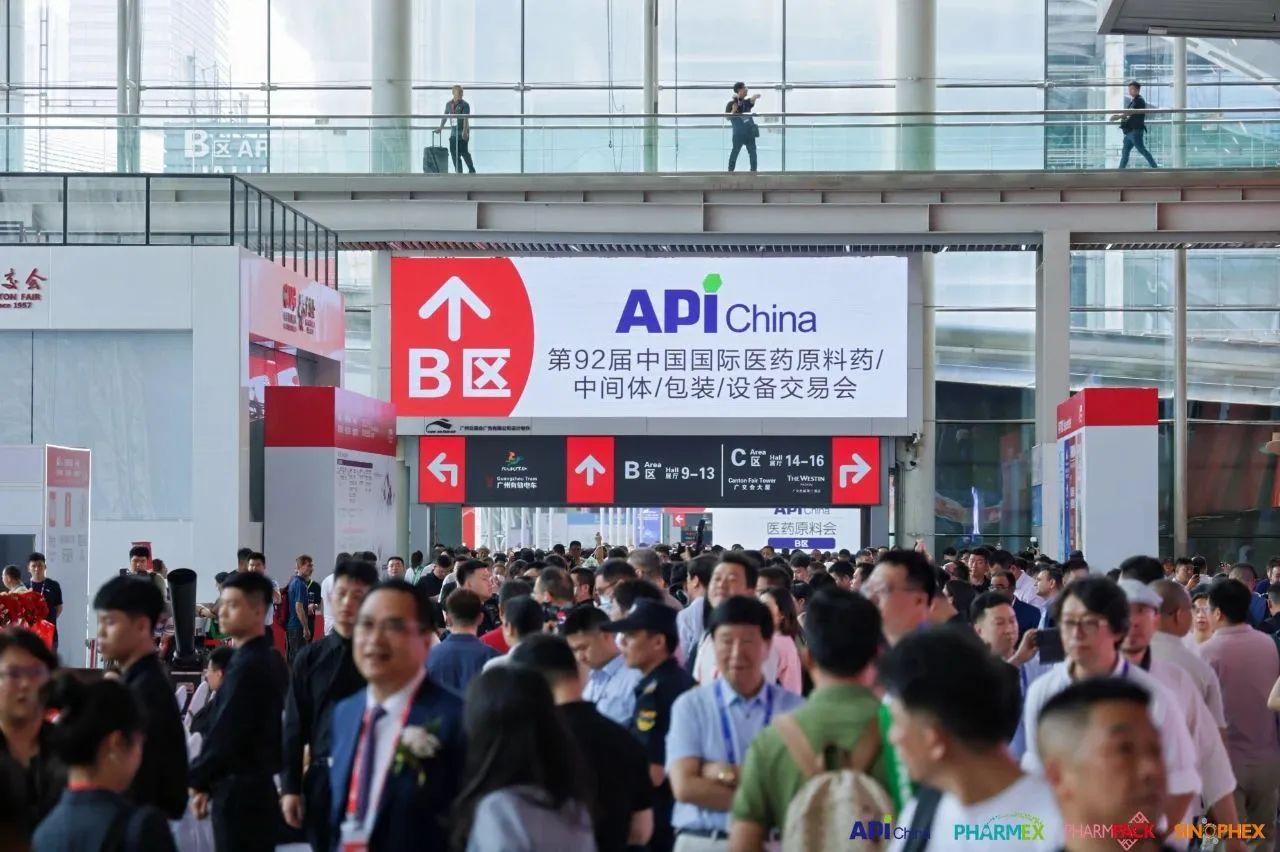

The 92nd API China Guangzhou – China International Pharmaceutical Ingredients Exhibition

As the longest-running pharmaceutical exhibition in China, API China was founded in 1968. The event showcases not only over 50,000 types of active pharmaceutical ingredients (APIs) across 24 major categories, but also all essential excipients, functional ingredients, packaging materials, and production & testing equipment for pharmaceuticals and health products.

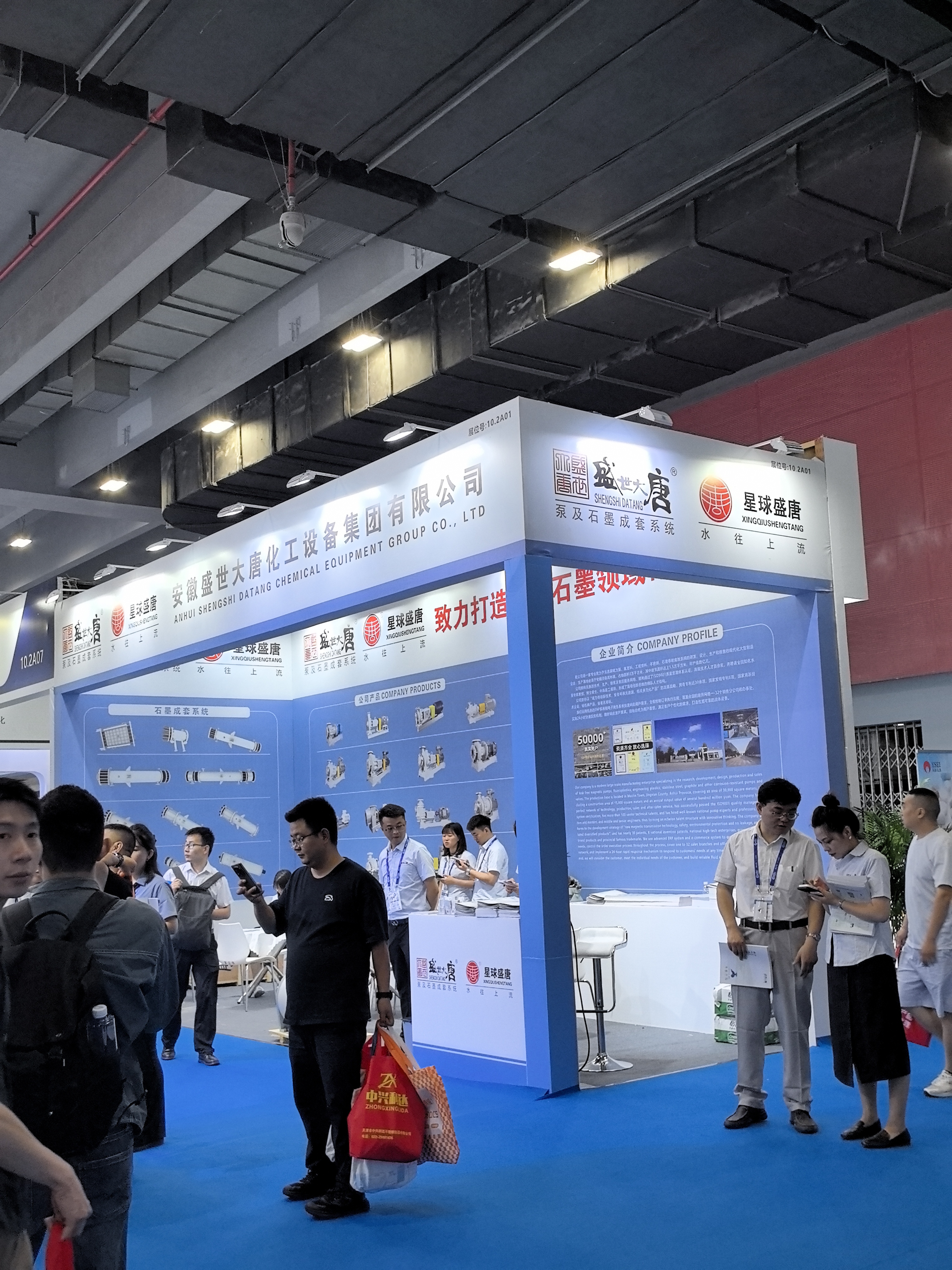

As a leading provider of pharmaceutical material handling equipment, Anhui Shengshi Datang Chemical Equipment Group Co., Ltd. exhibited in Hall 10.2, Area B of the Canton Fair Complex. Existing and potential clients visited our booth, engaging in in-depth discussions on the applications of chemical pumps and graphite equipment. Below are some on-site photos featuring our team and customers!

Shengshi Datang Group is an integrated industrial and trading company specializing in the production and sales of magnetic pumps and centrifugal pumps. These two types of pumps have distinct characteristics.

Magnetic pumps are suitable for hazardous media such as flammable, explosive, or toxic gases. Their advantages include safety, environmental friendliness, and leak-free operation. However, they also have drawbacks: they cannot transport liquids containing solids or particles, as the internal rotor may become clogged, and the diversion holes may fail to achieve optimal cooling and lubrication, potentially leading to overheating failures. Additionally, if the specific gravity of the medium exceeds 1.5, I do not recommend using magnetic pumps, as their magnetic coupling may slip, making it difficult to discharge the liquid.

Centrifugal pumps, on the other hand, are cost-effective and capable of handling high-specific-gravity substances. However, their mechanical seals have limited effectiveness and are prone to leakage over time, which can pollute the environment. Moreover, they can only handle liquids with particle or crystal content below 5%. If the content is up to 8%, it is advisable to use them in conjunction with double-flushed mechanical seals.

Benefits of Woven Silica Fabric and Textiles for Heat Protection

-

Exceptional Thermal Resistance

-

High-Temperature Stability: Silica fabrics withstand temperatures up to 1,800°F (982°C) and short-term exposure up to 2,300°F (1,260°C), ideal for extreme environments like furnaces or aerospace applications.

-

Low Thermal Conductivity: Acts as an effective thermal barrier, minimizing heat transfer to protect users or equipment.

-

Thermal Shock Resistance: Maintains integrity under rapid temperature changes, preventing cracks or degradation.

-

-

Chemical and Environmental Durability

-

Chemical Inertness: Resists corrosion from acids, alkalis, and solvents, ensuring performance in harsh industrial settings.

-

Weather and UV Resistance: Retains properties under UV exposure, moisture, and outdoor conditions, suitable for long-term outdoor use.

-

-

Mechanical and Physical Properties

-

Flexibility and Drapeability: Maintains flexibility despite high heat resistance, allowing use in complex shapes (e.g., protective clothing, pipe insulation).

-

Abrasion Resistance: Durable under mechanical stress, extending lifespan in demanding applications.

-

Lightweight: Offers high performance without the bulk of traditional materials like ceramics or metals.

-

-

Safety and Health Advantages

-

Non-Toxic and Asbestos-Free: Safer alternative to asbestos, with no hazardous fiber release when properly handled.

-

Flame Retardancy: Inherently non-combustible, with low smoke emission, enhancing safety in fire-prone environments.

-

Electrical Insulation: Provides dielectric properties, useful in electrical applications requiring heat protection.

-

-

Cost-Effectiveness and Sustainability

-

Long-Term Durability: Reduced replacement frequency lowers lifecycle costs.

-

Eco-Friendly: Derived from abundant silica sand, avoiding harmful byproducts associated with synthetic materials.

-

-

Versatile Applications

-

Protective Gear: Firefighting suits, welding blankets, and industrial gloves.

-

Industrial Use: Insulation for pipelines, turbines, and reactors in oil/gas industries.

-

Aerospace and Automotive: Heat shields and exhaust wraps.

-

Electrical Engineering: Insulation for high-temperature wiring and components.

-

Comparison to Alternatives

-

Outperforms fiberglass in temperature resistance and chemical stability.

-

Safer and more durable than asbestos, with better environmental credentials.

Considerations

-

While non-toxic, silica fibers should be handled to minimize inhalation risks.

-

Higher initial cost than some materials, offset by longevity and performance.

Woven silica textiles excel in combining thermal, chemical, and mechanical benefits, making them a superior choice for high-heat protection across diverse industries.

Fibreglass Ladder Tape is a premium-grade, tightly woven thermal insulation material crafted from high-bulk glass fibre yarns. Engineered with a unique "ladder effect" design—achieved by removing central yarns during weaving—this tape combines exceptional flexibility with structural integrity, making it ideal for demanding industrial applications. Withstanding temperatures up to +550°C, it delivers reliable performance in extreme heat environments while maintaining softness and pliability for easy handling.

Key Features

-

Extreme Heat Resistance: Operates reliably at temperatures up to +550°C (1000°F), perfect for furnaces, ovens, and exhaust systems.

-

Superior Insulation: Low thermal conductivity ensures optimal heat retention and energy efficiency.

-

Chemical Resilience: Resistant to oils, solvents, and most chemicals; inorganic, sterile, and non-combustible.

-

Durable & Flexible: Tightly woven texture retains strength while offering exceptional pliability for conforming to irregular surfaces.

-

Low Leachable Content: Minimal chlorides and fluorides, ensuring compliance with strict industrial standards.

-

Ladder Design: Open-center structure facilitates bolt-hole integration and simplifies installation in fabrication projects.

Applications

-

Thermal insulation for pipes, vessels, steam tracer lines, and duct flanges.

-

Sealing oven doors, boiler hatches, and furnace linings.

-

Stress relief in welding applications and gasketing.

-

Electrical insulation wrap, hose protection, and tadpole tape solutions.

-

Custom fabrication requiring bolt-hole compatibility.

Technical Specifications

-

Widths: 20mm to 500mm (custom options available)

-

Thickness: 1.5mm, 3.0mm, or 5.0mm

-

Coil Length: Standard 30m rolls (bulk orders customizable)

-

Compliance: Inorganic, non-toxic, and incombustible (meets industrial safety standards).

Why Choose Fibreglass Ladder Tape?

Designed for durability and versatility, this tape excels in both thermal management and mechanical sealing. Its unique ladder weave enhances airflow and installation flexibility, while its resistance to degradation ensures long-term reliability in harsh environments. Ideal for HVAC, manufacturing, and energy sectors seeking a robust, high-performance insulation solution.

Firesleeve Tape – Professional-Grade Thermal Protection Solutions by BSTFLEX

BSTFLEX offers two premium types of Firesleeve Tape, designed to enhance thermal protection, extend service life, and simplify installation in demanding environments. Whether you're sealing the ends of a Firesleeve installation or wrapping complex, high-temperature systems, our Firesleeve Tapes provide durable, reliable solutions tailored for industrial performance.

1. End Seal Tape – Pure Silicone Rubber Construction

Our End Seal Tape is manufactured from high-grade, pure silicone rubber and is engineered specifically for sealing the ends of installed Firesleeve. This helps to prevent the ingress of water, dirt, sand, dust, and other contaminants that can compromise thermal performance and hose integrity.

-

Self-Amalgamating Design: Unlike traditional tapes, this tape mechanically bonds to itself without any adhesive, forming a seamless, durable layer. The absence of glue means there’s no sticky residue and no compromise on thermal resistance.

-

High Temperature Performance: Designed to withstand extreme temperatures without degrading or losing strength.

-

Clean and Simple Application: Easy to install and remove, ensuring clean, professional finishes.

Typical Applications:

Transportation, Railroad, Oil & Gas, Industrial Machinery, Mining Equipment, Automotive Systems, Forestry, Military, Aerospace, Firefighting Gear, Rally Cars, and Smelters.

2. Firesleeve Tape – Silicone-Coated Fiberglass Construction

The Firesleeve Tape is a versatile, wrap-around thermal barrier composed of a durable fiberglass base with a high-performance silicone rubber coating. It delivers the same trusted protection as traditional Firesleeve but in a flexible, tape format.

-

Flexible Installation: Ideal for wrapping large-diameter components, irregular geometries, high-temperature piping, and foundry equipment.

-

Flame and Splash Resistance: Offers exceptional resistance to molten metal splash, radiant heat, and direct flame exposure.

-

Extended Equipment Lifespan: Helps prevent costly hose failures, reduces downtime, and protects workers from burns and equipment from heat-related damage.

Ideal For:

Foundry systems, engine compartments, heat-intensive piping, maintenance wraps, and retrofit applications across industrial, automotive, and aerospace sectors.

Choose BSTFLEX Firesleeve Tape

Engineered for durability, designed for convenience—BSTFLEX Firesleeve Tapes are your go-to solutions for reliable thermal protection in the most challenging environments.

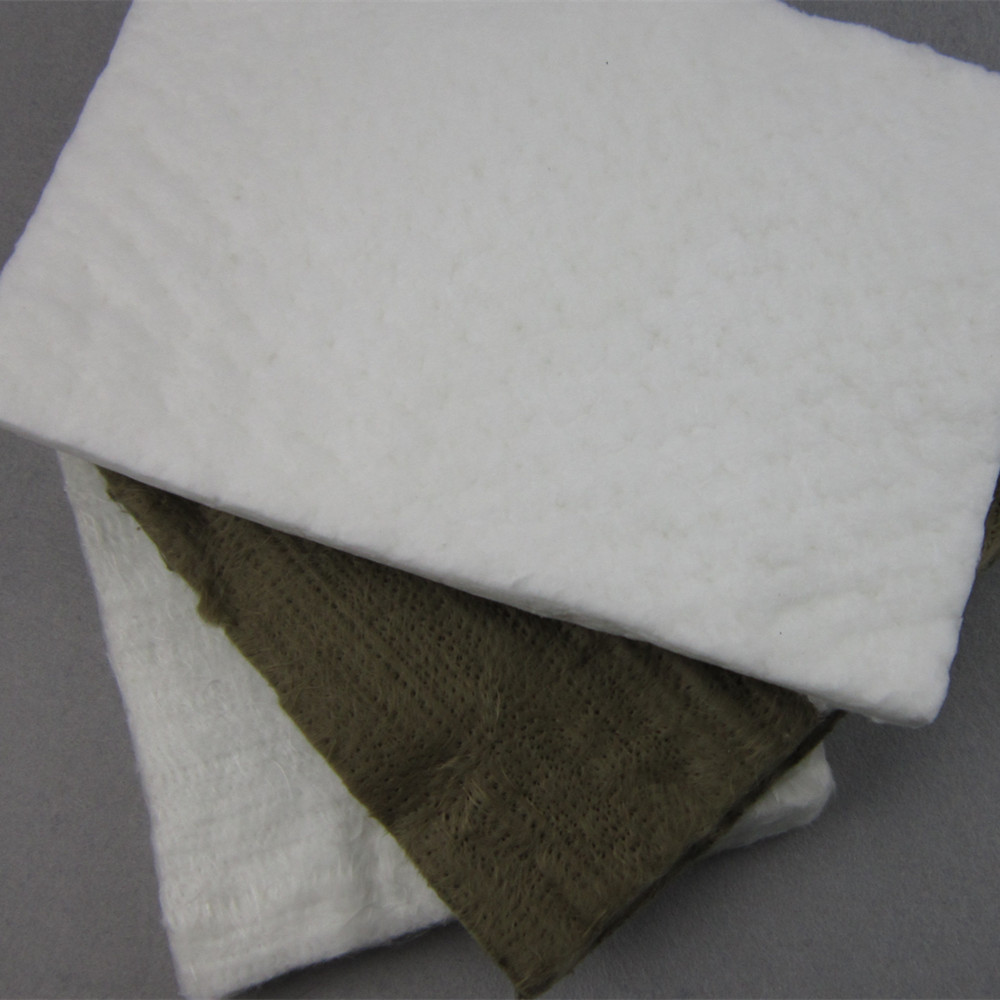

1. Silica Needle Mat

-

Material Base: Pure amorphous silica fibers (≥96% SiO₂ content), processed into a dense, needled structure.

-

Thermal Performance:

-

Continuous Use: 1000°C (1832°F), with short-term tolerance up to 1260°C (2300°F).

-

Minimal linear shrinkage (<2%) at 1000°C, ensuring long-term dimensional stability.

-

-

Key Advantages:

-

Chemically inert: Resistant to acids, alkalis, and oxidation even in extreme heat.

-

Ultra-low thermal conductivity (0.035–0.045 W/m·K) for superior heat retention.

-

Non-combustible (Class A fire rating) and zero volatile emissions.

-

-

Typical Use Cases:

-

High-temperature exhaust components (turbochargers, headers, racing exhaust systems).

-

Critical thermal shielding in aerospace, foundries, and power generation.

-

2. Fiberglass Needle Mat

-

Material Base: E-glass fibers (calcium-aluminoborosilicate glass) bonded into a flexible mat.

-

Thermal Performance:

-

Continuous Use: 450–550°C (842–1022°F), with some modified grades surviving brief exposure to 700°C (1292°F).

-

-

Key Advantages:

-

Cost-efficient: ~50–70% cheaper than silica-based solutions.

-

Excellent sound absorption (NRC 0.65–0.85) for noise reduction in exhaust systems.

-

Easily cut and molded to fit irregular surfaces (density: 60–100 kg/m³).

-

-

Limitations:

-

Gradual fiber embrittlement above 500°C, risking particulate release.

-

Potential formaldehyde release in humid, high-heat environments (requires UL GREENGUARD certification).

-

Direct Performance Comparison

| Parameter | Silica Needle Mat | Fiberglass Needle Mat |

|---|---|---|

| Peak Temperature | 1260°C (2300°F) | 700°C (1292°F) short-term |

| Thermal Conductivity | 0.035–0.045 W/m·K | 0.05–0.08 W/m·K |

| Chemical Resistance | Exceptional (pH 1–14 stable) | Moderate (degrades in strong acids) |

| Acoustic Damping | Limited (NRC 0.3–0.4) | High (NRC 0.7–0.85) |

| Lifespan at 600°C | 10+ years | 2–5 years |

Application Recommendations

-

Turbocharged/Diesel Exhausts:

-

Use silica mats near turbos/DPFs where gas temps exceed 800°C.

-

Fiberglass suits tailpipes/mufflers (<500°C).

-

-

Weight-Sensitive Designs:

-

Silica: Higher cost but 30% lighter than ceramic fiber alternatives.

-

Fiberglass: Budget-friendly for non-critical thermal zones.

-

-

BSTFLEX specializes in advanced Basalt Sleeve solutions designed to safeguard critical components in extreme thermal conditions. Engineered from high-performance basalt fibers, our sleeves deliver unmatched heat resistance, durability, and flame retardancy, making them ideal for industries where reliability and safety are non-negotiable.

Product Overview

-

-

Wall Thickness: ~2 mm (single-sided).

-

Features: Flexible, lightweight, and easy to install. Perfect for applications requiring moderate abrasion resistance and consistent thermal shielding up to 1,000°C.

-

Applications: Exhaust systems, turbocharger hoses, and engine bay wiring in automotive sectors; thermal management in aerospace hydraulic lines.

-

-

-

Wall Thickness: Customizable (1 mm, 1.5 mm, 2 mm, 3 mm).

-

Features: High-density braided structure for enhanced mechanical strength and superior protection against extreme heat (up to 1,200°C), sparks, and molten splatter.

-

Applications: Power plant cable insulation, industrial furnace piping, welding equipment, and heavy machinery in high-temperature environments.

-

-

Why Basalt Fiber?

-

Exceptional Thermal Resistance: Basalt fibers withstand temperatures exceeding 1,200°C, outperforming traditional materials like fiberglass or silica.

-

Abrasion & Chemical Resistance: Protects against wear, corrosion, and industrial chemicals.

-

Flame Retardant: Self-extinguishing properties ensure compliance with fire safety standards (e.g., ISO 6941, UL 94 V-0).

-

Eco-Friendly: Inorganic, non-toxic, and derived from volcanic rock, ensuring minimal environmental impact.

-

Real-World Applications

-

Automotive: Extended lifespan of EV battery cables and hybrid vehicle exhaust components.

-

Aerospace: Thermal shielding for fuel lines and avionics in jet engines.

-

Energy: Insulation for geothermal power plant steam pipes and solar thermal systems.

-

Manufacturing: Protection for robotic arms and conveyor systems in foundries.

-

BSTFLEX Advantages

-

Customizable Solutions: Tailored thickness, diameter, and length to meet specific operational needs.

-

Durability: Reduces downtime by preventing hose/cable degradation in harsh conditions.

-

Cost-Effective: Lowers maintenance costs and replacement frequency.

Elevate your equipment’s performance and safety with BSTFLEX basalt sleeves—where innovation meets industrial resilience.

Contact BSTFLEX today to explore bespoke thermal protection solutions for your industry!

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2