Standard Color Coding for Webbing Slings According to EN 1492

Webbing slings are widely used in lifting operations across construction, logistics, and industrial sectors. To ensure safety and efficiency, webbing slings are color-coded according to the EN 1492 standard, which specifies the working load limits (WLL) for different sling capacities. Understanding this color coding allows operators to select the correct sling for each lifting task.

Importance of Color Coding

Color coding provides several key benefits:

Safety: Enables quick identification of the working load limit, reducing the risk of overloading.

Efficiency: Simplifies selection and inspection of slings, saving time during operations.

Compliance: Ensures lifting equipment meets international safety requirements as specified by EN 1492.

At NANJING D.L.T SLING CO., LTD, our webbing slings are manufactured in strict accordance with EN 1492 and feature durable, standardized color coding to support safe and reliable lifting.

EN 1492 Webbing Sling Color Codes

|

Color |

Working Load Limit (WLL) |

Notes |

|

Violet |

1 tonne |

Standard capacity for general lifting |

|

Green |

2 tonnes |

Higher capacity for heavier loads |

|

Yellow |

3 tonnes |

High-visibility for specialized operations |

|

Grey |

4 tonnes |

Suitable for heavy-duty applications |

|

Red |

5 tonnes |

Increased lifting capacity |

|

Brown |

6 tonnes |

For very heavy loads |

|

Blue |

8 tonnes |

Designed for industrial applications |

|

Orange |

10 tonnes |

Maximum WLL for standard webbing slings |

The EN 1492 standard defines color codes for polyester and polyamide webbing slings according to their working load limits. The commonly used color codes are:

Best Practices for Using Color-Coded Webbing Slings

Follow EN 1492 Standards: Ensure all webbing slings comply with EN 1492.

Inspect Slings Regularly: Check for signs of wear, fraying, or damage before each use.

Select Appropriate Sling: Choose a sling with a suitable WLL according to the color code.

Provide Training: Operators should be trained in proper handling and color-code identification to maintain safety.

Standard color coding of webbing slings under EN 1492 provides a clear and reliable method to ensure safe lifting operations. Correct identification of sling capacity promotes safety, operational efficiency, and compliance with international standards.

NANJING D.L.T SLING CO., LTD offers high-quality EN 1492-compliant webbing slings with durable and accurate color coding. Our products are engineered for safety, reliability, and performance in demanding industrial environments.

Contact us to learn more about our webbing slings or to request a sample.

Flat webbing slings are one of the most widely used lifting tools across industries such as construction, mining, logistics, shipping, and manufacturing. They are lightweight, flexible, easy to handle, and capable of lifting heavy loads safely. However, the reliability of a webbing sling depends on how it is designed, manufactured, and used.

In Australia, flat webbing slings must comply with the **Australian Standard AS 1353**, which sets clear rules for product quality and safe operation. At **NANJING D.L.T SLING CO., LTD**, we manufacture lifting products that meet or exceed international standards, including AS 1353, ensuring that our customers can work with confidence in demanding environments.

The **Australian Standard AS 1353** is specifically written for flat synthetic webbing slings made of man-made fibers, such as polyester. It provides guidance for both manufacturers and users to guarantee safe lifting practices.

This standard is divided into two main parts:

- **AS 1353.1 – Product requirements**

Covers the technical specifications for materials, construction, performance, testing, and labeling.

- **AS 1353.2 – Safe use**

Provides guidelines for users, including inspection procedures, rejection criteria, and safe lifting practices.

Together, these two parts ensure that the slings are not only manufactured correctly but also used safely throughout their service life.

## Key Requirements for Flat Webbing Slings under AS 1353

1. **Material**

- Slings must be made from high-strength synthetic fibers such as polyester.

- The material should be resistant to abrasion, moisture, UV rays, and many common chemicals.

2. **Safety Factor**

- All slings must have a **minimum safety factor o**

3. **Color Coding System**

- A standardized color system is used for easy identification of WLL:

- Purple – 1 tonne

- Green – 2 tonnes

- Yellow – 3 tonnes

- Grey – 4 tonnes

- Red – 5 tonnes

- Brown – 6 tonnes

- Blue – 8 tonnes

- Orange – 10 tonnes

This system helps workers quickly identify the right sling for each lifting task.

4. **Labeling**

- Every sling must have a durable label that includes:

- Working Load Limit (WLL)

- Manufacturer’s name or trademark

- Material type

- Standard compliance (AS 1353)

- Safety instructions

If the label is missing or unreadable, the sling must not be used.

5. **Testing & Inspection**

- Each sling must undergo proof load testing during production.

- Users are required to carry out regular inspections before each lift.

- Damaged or defective slings should be removed from service immediately.

## Why AS 1353 Compliance Matters

Lifting operations always involve risk, and non-compliant equipment can cause accidents, injuries, or costly downtime. By using slings that comply with **AS 1353**, businesses can:

- **Guarantee safety** for workers and equipment.

- **Improve efficiency** by using properly rated slings for each job.

- **Extend service life** through high-quality construction and correct use.

- **Build trust** with clients and partners by showing commitment to safety standards.

For industries such as construction and mining, where heavy lifting is a daily task, compliance with AS 1353 is not just a legal requirement but also a critical safety measure.

Our Commitment to Quality

At **NANJING D.L.T SLING CO., LTD**, we specialize in the production of a wide range of lifting and securing products, including:

- Flat webbing slings

- Endless round slings

- High-performance fiber slings

- Ratchet straps and tie-downs

- Cargo nets and lifting nets

With advanced weaving and stitching machines, strict quality control, and professional testing facilities, we ensure that every sling leaving our factory meets the required international standards.

We also provide **CE and GS certified products** and can customize labeling with your company logo. Our current product range includes slings with a maximum lifting capacity of **up to 1100 tonnes**, covering both standard and special requirements.

Selecting the right teeth knife is essential for achieving clean, efficient, and cost-effective cutting results in industrial applications. Whether you're working in the packaging, food processing, plastic, or rubber industry, using a knife tailored to your specific cutting task can significantly improve productivity and product quality.

The first factor to consider is material compatibility. Different materials require different types of teeth knives. For example, soft materials like plastic films or paper benefit from fine-toothed blades, while tougher materials like rubber or composite layers may need coarse, reinforced teeth for aggressive cutting action.

Another critical aspect is tooth design. The shape, size, and spacing of the teeth determine the cutting efficiency and edge finish. Straight teeth offer consistent slicing, whereas serrated or scalloped designs are better suited for gripping and tearing through fibrous or layered materials.

Blade material also plays a key role. High-speed steel (HSS), tungsten carbide, and stainless steel are popular choices, each offering different levels of hardness, wear resistance, and corrosion protection. Coatings such as TiN (Titanium Nitride) can further enhance blade longevity in high-friction environments.

Finally, consider whether the lcknife blade is re-sharpenable or disposable. Reusable knives offer long-term value and sustainability, while disposable types are suitable for environments requiring strict hygiene or fast blade changes.

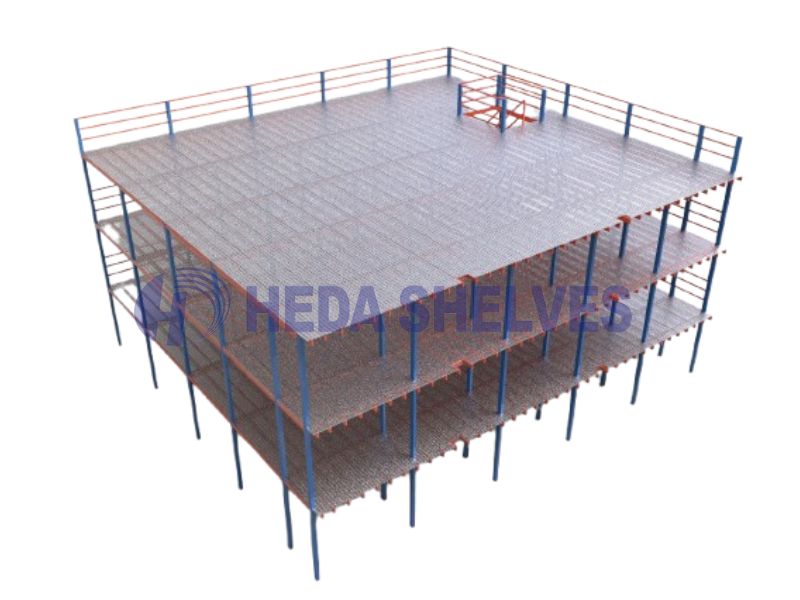

A mezzanine floor is one of the most effective ways to maximize vertical warehouse space without the cost of moving or constructing a new facility. It creates an intermediate level inside a building for storage, offices, or production. For distributors, e-commerce hubs, and manufacturers, mezzanines allow flexible expansion with minimal downtime.

However, selecting the wrong mezzanine system or overlooking critical design factors can lead to costly mistakes, safety hazards, and even compliance issues.

What Is the Weight Limit for a Mezzanine Floor?

Every mezzanine has a defined load-bearing capacity, usually measured in kilograms per square meter (kg/m²). This load rating ensures the structure can safely support people, equipment, and goods.

Standard light-duty mezzanines may support 250–350 kg/m², while heavy-duty warehouse mezzanines can be engineered for 500–1,000+ kg/m² depending on use. Exceeding these limits risks structural failure.

How Much Weight Can a Warehouse Mezzanine Floor Hold?

The answer depends on the design standard and intended use. For example:

- Storage of light cartons or shelving: ~300 kg/m²

- Palletized goods or machinery: 500–1,000 kg/m²

- Office use or personnel access: 250–350 kg/m²

Professional manufacturers design mezzanines according to international codes such as EN 1991, ANSI MH28.3, or local building regulations. Always request a stamped engineering report before installation.

Pallet Racking vs Mezzanine Floor

While pallet racking maximizes vertical storage for pallets, a mezzanine creates an entire additional floor area. The two systems can also work together: a rack-supported mezzanine combines structural racking uprights with elevated flooring, providing both pallet storage and accessible workspace. Choosing between them depends on operational needs—racking is best for bulk pallet handling, while mezzanines suit mixed storage, picking, and office integration.

Mistakes of Mezzanine Kits Design (Top 10 Pitfalls to Avoid)

1. Ignoring Weight Limits

Overloading a mezzanine is one of the fastest ways to compromise safety. Many buyers underestimate the actual load of pallets, forklifts, or shelving systems. Always calculate live and dead loads precisely.

2. Skipping Safety Measures

Handrails, toe boards, safety gates, and anti-slip flooring are not optional. OSHA and local regulations mandate them for worker protection. Cutting corners here leads to accidents and liability issues.

3. Forgetting About Lighting

A mezzanine can cast shadows on the floor below, creating dark, unsafe areas. Poor visibility reduces productivity and increases risks during forklift or picking operations. Plan for integrated LED lighting systems both above and below the structure.

4. Neglecting Fire Safety

Fire sprinklers, smoke detectors, and fire-rated materials are often overlooked. Most jurisdictions require mezzanine floors to integrate with the building’s fire protection system.

5. Using the Wrong Flooring Material

Not all floor panels are equal. Chipboard may be cost-effective but absorbs moisture. Steel grating provides ventilation but is noisy. Choose materials based on intended use: office areas need smooth laminate, while industrial zones may require galvanized steel.

6. Not Considering Ventilation

Enclosed mezzanines trap heat and dust. Lack of airflow creates uncomfortable working conditions and may violate occupational safety standards. Incorporate ventilation or fans into the design.

7. Creating a Dead Zone Underneath

Some mezzanines are poorly planned, leaving awkward, unusable spaces beneath. The underside should be designed for racking, workstations, or forklift aisles to maximize ROI.

8. Forgetting About Maintenance

Like any structure, mezzanines require inspections. Loose bolts, worn flooring, or corrosion must be addressed early. Neglecting maintenance shortens lifespan and increases risks.

9. DIY Electrical Work

Running cables or lighting without licensed electricians is dangerous and often illegal. Electrical integration should be part of the professional mezzanine installation package.

10. Ignoring Building Codes

Local codes regulate mezzanine size, egress, safety barriers, and fire protection. Failing to comply can lead to fines, forced removal, or legal action. Always verify compliance with certified engineers.

Load Standards & Storage

International mezzanine design follows strict standards:

- EN 1090 & EN 1991 (Europe)

- ANSI MH28.3 (U.S.)

- AS 1657 (Australia)

Storage type determines the load class: light shelving, medium carton flow, or heavy pallet zones. Correct classification ensures efficiency and safety.

Investing in a mezzanine floor is not just a construction project—it is a business growth strategy. By expanding vertically, companies save on relocation, lease, and land costs. The ROI of a professionally designed mezzanine often exceeds 200% within 3 years, especially for e-commerce, 3PL, and manufacturing firms.

Conclusion

A mezzanine floor can double your usable space and improve workflow, but only if designed correctly. Ignoring weight limits, safety, and compliance can turn an investment into a liability. Partner with a professional mezzanine manufacturer who provides engineering support, compliance documentation, and turnkey installation.

At HEDA SHELVES, we deliver custom mezzanine racking systems engineered to international standards, ensuring safety, efficiency, and long-term storage to your warehouse operations.

Injection molded magnets help electric motors work better and run smoother. These magnets are made by mixing magnetic powders and polymer binders. They are now very important in modern rotary systems. Manufacturers like injection molded magnets because they can be made in special shapes. They also allow for tight fits and custom magnetization. ZOYN’s advanced process makes sure the magnets are exact, steady, and strong.

-

In the last ten years, more people have started using injection molded magnets. This is because more electric vehicles and energy-saving parts are needed.

-

The motors segment made up 35% of market money in 2023. This shows they are used a lot in cars and factories.

Injection Molded Magnets for Electric Motors have clear benefits over old types.

Key Takeaways

-

Injection molded magnets help make strong and light magnets. They can be made in many shapes. These shapes fit well inside electric motors.

-

These magnets do not rust easily. They do not need extra coatings. This helps motors last longer in hard places.

-

The way they are made keeps the quality steady. It also makes sure the sizes are exact. This helps motors work well and stay quiet.

-

These magnets can handle high heat, up to 180°C. This is good for cars and big machines.

-

Many industries use these magnets. They help build smaller motors that work better. These motors save energy and cost less to make.

Injection Molded Magnets Overview

What Are Injection Molded Magnets

Injection molded magnets are special magnetic parts. They are made by mixing magnetic powders with polymer binders. Some materials used are neodymium-iron-boron, samarium-cobalt, and hard ferrites. Hard ferrites can be barium or strontium ferrite. The kind of magnetic powder changes how the magnet works. It also changes how the material moves during making. Polyamide 12 and thermoplastic copolyester elastomers are common binders. These binders make the magnet strong and help stop rust. The amount of powder and binder changes the magnet’s strength and bendiness. More powder makes the magnet stronger. But it can also change how the material acts and flows.

Injection molded magnets are important in electric motors and rotary systems. Their design lets them have tricky shapes and close fits. This is needed for new motor designs. These magnets can be made for different jobs. They can be different sizes, shapes, and have special magnetization.

Manufacturing Process

Making these magnets uses careful steps that are not like old ways. The table below shows the main differences:

|

Step/Feature |

Injection Molding Process for Magnets |

Differences from Other Methods |

|---|---|---|

|

Material Preparation |

Mix magnetic powder with polymer binder |

Sintering uses powder only; compression bonding uses epoxy |

|

Molding |

Inject molten compound into molds, sometimes with an external magnetic field for orientation |

Sintering presses and heats powders; compression bonding presses and cures |

|

Cooling and Solidification |

Cool in mold to solidify shape |

Sintering requires high heat; compression bonding cures after pressing |

|

Shape and Complexity |

Enables complex shapes and multi-part assemblies |

Sintered magnets have shape limits |

|

Magnetic Orientation |

External field during molding for anisotropic magnets |

Other methods magnetize after forming |

First, magnetic powder and binder are mixed together. This makes a thick plastic material. The material is pushed into a mold. It cools down and becomes the right shape. Many molds can be used at once to make lots of magnets. This process lets people make detailed shapes and parts. That is why injection molded magnets are great for new electric motors.

Benefits of Injection Molded Magnets

Design Flexibility

Injection molded magnets give engineers many design choices. They can make shapes that old sintered magnets cannot. The process lets them create detailed and special forms. By mixing magnetic powders with polymer binders, they can mold magnets with fine details. This helps make electric motors smaller. It also lets one part do many jobs.

Injection molding lets makers control the magnet’s strength as it cools. They can change the magnetic field to fit what is needed. This is very important for new electric motor designs.

Magnets can have custom magnetization patterns like axial, radial, or multipole. This gives even more design options. These features are great for places with little space and high performance needs.

Precision and Consistency

Injection molded magnets are known for being precise and steady. The process makes sure each magnet fits just right. The tolerances are not always as tight as sintered magnets. But they still keep good balance and quality.

|

Aspect |

Injection Molded Magnets |

Sintered Magnets |

Advantage of Injection Molded Magnets |

|---|---|---|---|

|

Dimensional Accuracy |

High, with good product consistency |

Lower, less consistent |

Reliable fit and stable quality |

|

Magnetic Properties |

Stable, with high surface magnetic field |

Very high, but less stable |

Consistent performance in motor applications |

|

Multipolarization |

Complex shapes possible |

Limited, costly for complex shapes |

Greater design freedom |

|

Reliability |

Tough, resistant to breakage |

Brittle, prone to chipping |

Increased service life |

This process also makes light and small parts. Hard magnetic powder is put into thermoplastic resin. This makes motor parts lighter but still strong. It is good for electric and smart vehicles. These vehicles need to save energy and work well.

-

Injection molded magnets help make motors smaller.

-

The process allows making many magnets with steady quality.

-

Small designs help motors work better and use less energy.

Durability and Corrosion Resistance

Injection molded magnets are tough and resist rust. The mix of powders and binders makes them strong. They can handle hits, shaking, and rough places. They work well in hot and cold, from -40°C to 180°C. This makes them good for cars and factories.

These magnets are very good at fighting rust. The plastic binder covers the magnetic pieces. This keeps out water and air. Most times, they do not need extra coatings. Sintered magnets often need nickel, zinc, or epoxy to stop rust.

Injection molded magnets last a long time in wet or salty places.

Making these magnets costs less when making many at once. The process does not need high heat like sintering. This saves money. That is why they are a smart pick for big orders and tricky designs.

Injection Molded Magnets for Electric Motors

Performance Advantages

Injection molded magnets help electric motors work better. Engineers use these magnets to make motors run smoothly and last longer. The way these magnets are made lets people control their shape and magnetization. This helps motors work well in tough places.

ZOYN’s rotor injection molded magnets are very light. This makes motor parts weigh less. They are good for fast motors and places with little space. The polymer binder in the magnets stops rust. This helps motors last longer in rough conditions.

ZOYN’s magnets can be magnetized in different ways. Engineers can pick axial, radial, or multipole patterns. This helps them make the magnetic field fit each motor.

These magnets keep their magnetic power even when hot. Some special types work up to 180°C. This is important for cars and factories. The molding process makes sure each magnet fits just right. This lowers vibration and noise. Motors with these magnets run smoother and need less fixing.

|

Feature |

Impact on Electric Motors |

|---|---|

|

Lightweight Design |

Makes motors faster and saves energy |

|

Tight Tolerances |

Cuts down on vibration and noise |

|

Custom Magnetization Patterns |

Helps control the magnetic field |

|

Corrosion Resistance |

Makes motors last longer |

|

Temperature Stability |

Keeps motors working well |

These magnets can be made in large numbers. Factories can make thousands of the same magnet fast. This saves money and keeps quality high. That is why many people pick injection molded magnets for new electric motors.

Application Examples

Injection molded magnets are used in many industries. Car makers use them to build small and strong motors for electric vehicles. For example, samarium-iron-nitrogen magnets help make motors smaller and lighter. Scientists are working to make these magnets even better. This could help with rare earth supply and prices.

-

These magnets can be made in tricky shapes and exact sizes.

-

Car engineers use them in gear shift indicators and sensor mounts.

-

Audi seat sensors use these magnets ordered by German customers.

-

Electric car motors need magnets that do not lose power or break. N48SH magnets in Tesla cars work at 180°C and stop tiny cracks.

|

Magnet Type |

Max Temperature |

Key Applications |

Strength (BHmax) |

|---|---|---|---|

|

Injection Molded |

120°C |

Custom mounts, clips |

3-7 MGOe |

Renewable energy systems also use these magnets. BLDC motors in wind turbines and solar trackers use them to work better and save space. Neodymium magnets, even bonded ones, are common in wind turbines and solar trackers. These magnets turn spinning into electricity and help solar panels move just right.

-

Injection molded magnets are strong and last a long time.

-

Wind turbines use them on rotors to make electricity.

-

Solar trackers use them to move panels exactly.

-

Their strength and light weight help make energy with less material.

Factories and robots need these magnets to work well and stay steady. ZOYN’s rotor magnets show how custom designs help. They give the right magnetic field and can handle tough places. This makes them important for machines that work by themselves.

Injection molded magnets give motors the power, accuracy, and trust needed for cars, green energy, and factory machines.

Engineers pick these magnets because they work well, can be shaped in many ways, and last a long time. These magnets help new ideas grow in many fields.

Magnet Comparison

Sintered vs. Injection Molded Magnet

Sintered magnets and injection molded magnets are not the same. Sintered magnets are made by pressing powder together and heating it up. This makes magnets with strong magnetic power, but it costs more to make them. Injection molded magnets are made by mixing magnetic powder with a plastic binder. They are shaped using heat and pressure. This way, they can be made into many shapes and cost less.

-

Injection molded neodymium magnets are cheaper to make than sintered magnets.

-

Sintered magnets are stronger but cost more to produce.

-

Injection molded magnets can be made in many shapes and in large numbers, so they are good for making electric motors.

|

Feature |

Sintered Magnets |

Injection Molded Magnets |

|---|---|---|

|

Manufacturing Cost |

High |

Lower |

|

Shape Flexibility |

Limited |

High |

|

Magnetic Performance |

Superior |

Adequate for most motors |

|

Production Volume |

Moderate |

High |

Bonded vs. Injection Molded Magnets

Bonded magnets can be made by injection molding or compression molding. Both types use magnetic powders and plastic binders. This lets them be made in tricky shapes with good accuracy. Injection molding is special because it makes parts that are stronger and more exact.

-

Both bonded and injection molded magnets can have detailed shapes.

-

Injection molded magnets are stronger and more alike in size.

-

Making bonded magnets with injection molding saves material and needs less extra work.

|

Property |

Injection Molded Magnets |

Bonded Magnets (General) |

|---|---|---|

|

Mechanical Strength |

High |

Lower |

|

Shape Freedom |

Large |

Limited |

|

Dimensional Accuracy |

High |

Lower |

|

Magnetic Properties |

Adjustable |

Best when injection molded |

|

Product Consistency |

Good |

Less consistent |

Ferrite vs. Injection Molded Magnets

Ferrite magnets are made from cheap and easy-to-find materials. They are good for making lots of magnets at once. They do not rust easily and can handle heat. Injection molded magnets use magnetic powders, like ferrite, mixed with plastic. This way, they can be made in many shapes and in big amounts for less money.

-

Ferrite magnets are best when making many magnets for less money.

-

Injection molded magnets are better for making tricky shapes.

-

Bonded magnets have higher electrical resistivity, which helps in some uses.

-

Using special plastics lets injection molded magnets work in hotter places.

Injection molded magnets are getting more popular because they are easy to make and work well in new electric motors.

More companies now use injection molded magnets. Car makers, electronics, and factories like them because they are light and small. They are easy to make in big numbers. Studies show more electric cars, medical tools, and gadgets use these magnets. Makers like that they can make exact parts that are strong. This helps new ideas in electric motor design.

Injection molded magnets help electric motors in special ways. They do not rust, so no extra coating is needed. These magnets are made to fit very well and work right every time. They can handle high heat, so they work in hot places. Their shapes can be tricky, which helps make new motor designs.

|

Advantage |

Benefit |

|---|---|

|

Corrosion Resistance |

No need for extra coating |

|

Dimensional Accuracy |

Tight tolerances for reliable performance |

|

Temperature Resistance |

Works well in high-heat environments |

|

Complex Shapes |

Supports advanced motor designs |

New ways to make magnets, like 3D printing, let companies make magnets for special jobs. People who choose parts for motors should look at these magnets. They help make motors lighter, work better, and cost less.

FAQ

What makes injection molded magnets different from sintered magnets?

Injection molded magnets are made with magnetic powder and a polymer binder. Sintered magnets use just powder and heat to form them. Injection molded magnets can be shaped in many ways and fit tightly. Sintered magnets are stronger but cannot be shaped as easily.

Can injection molded magnets resist corrosion?

Yes. The polymer binder covers the magnetic pieces inside the magnet. This layer keeps out water and stops rust from forming. Most of the time, no extra coating is needed.

Where do engineers use injection molded magnets in electric motors?

Engineers put these magnets in rotors, sensors, and actuators. They help motors work well and fit into small spaces. Car makers, green energy, and factories use them a lot.

How do injection molded magnets improve motor efficiency?

Injection molded magnets make motors lighter and fit better. This helps lower shaking and noise. Motors work better and last longer.

Are injection molded magnets suitable for high-temperature environments?

Yes. Some types of injection molded magnets work up to 180°C. This makes them good for cars and factories where it gets hot.

Choosing the right sintered neodymium magnet means you must match your needs to what the magnet can do. You want a magnet with strong neodymium power. But you also need to think about its shape and size. You should check if the magnet’s properties fit your project. Sintered neodymium magnets can have problems like cracks, scratches, or dents. They are brittle, so shaping them is hard. Even small defects can change how the magnet works. If you focus on the right properties and know these problems, you can pick a sintered magnet that works for you.

Key Takeaways

-

Make sure the magnet's strength, size, shape, and temperature rating fit your project's needs for best results.

-

Pick the right magnet grade to balance power, heat resistance, and cost.

-

Choose a coating that keeps your magnet safe from rust and damage, depending on where you will use it.

-

Learn if the magnetization direction is axial or radial so your magnet works well in your project.

-

Try out sample magnets and ask experts for help to avoid mistakes and get magnets that last a long time.

Application Needs

Before you choose a sintered neodymium magnet, you must know what your project needs. If you figure out your needs first, you can save money and make sure your magnet works well. Let’s look at the main things to think about.

Magnetic Strength

First, think about how much pull force you need. Do you want the magnet to hold something heavy or just a small part? Sintered neodymium magnets are known for being very strong. The sintering process packs neodymium powder tightly. This makes the magnets strong and stable, even in tough places. That is why they are used in electric car motors, wind turbines, and MRI machines. These places need strong magnets in small spaces.

Here is a table that shows how magnetic strength changes by use:

|

Application Type |

Magnet Type |

Magnetic Strength (Tesla) |

Key Considerations |

|---|---|---|---|

|

High-performance industrial |

Sintered Neodymium |

Up to 1.4 |

Needed for compact, high-force applications (e.g., EV motors, MRI machines) |

|

Moderate strength consumer |

Ferrite |

0.2 - 0.5 |

Used where space and strength demands are lower (e.g., refrigerator magnets, speakers) |

|

Environmental conditions |

Both (varies) |

N/A |

Ferrite favored for thermal stability; Neodymium requires coatings for durability |

|

Manufacturing process |

Sintered Neodymium |

Enhanced strength & durability due to sintering |

|

|

Cost and size constraints |

Both |

N/A |

Neodymium chosen for strength-to-size ratio despite higher cost; ferrite for cost-effectiveness |

You should always match the pull force and magnetic strength to your project. If you need a magnet for a wind turbine or electric car, you want the strongest one. For a speaker, you can use a weaker magnet.

Tip: Always check the pull force for your magnet. This tells you how much weight it can hold. It helps you avoid picking a magnet that is too weak or too strong.

Size and Shape

The size and shape of your magnet are important. You need to make sure the magnet fits your space and gives the right pull force. Sintered neodymium magnets come in many shapes. Some are discs, blocks, rings, arcs, or even tiny custom magnets. Each shape has its own size range and limits.

|

Typical Size Range (mm) |

|

|---|---|

|

Disc Magnets |

Diameter: 1–20; Thickness: 1–10 |

|

Block Magnets |

Length: 5–300; Width: 2–50; Thickness: 1–50 |

|

Ring Magnets |

Outer Diameter: 5–200; Inner Diameter: 2–150; Thickness: 1–50 |

|

Arc/Segment Magnets |

Outer Radius: 30–60; Inner Radius: 20–40; Thickness: 8–15 |

|

Plate/Grid Magnets |

Up to 300 x 300 (for separators or lifting systems) |

|

Pot/Cup Magnets |

Diameter: 20–100; Height: 5–25 |

|

Custom Micro-Magnets |

Any dimension: 0.5–5 |

Standard limits help your magnet meet the exact size you need. For example, disc magnets can have very tight size limits. Always check the size and shape before you buy. This way, your magnet will fit and work as you want.

Temperature Range

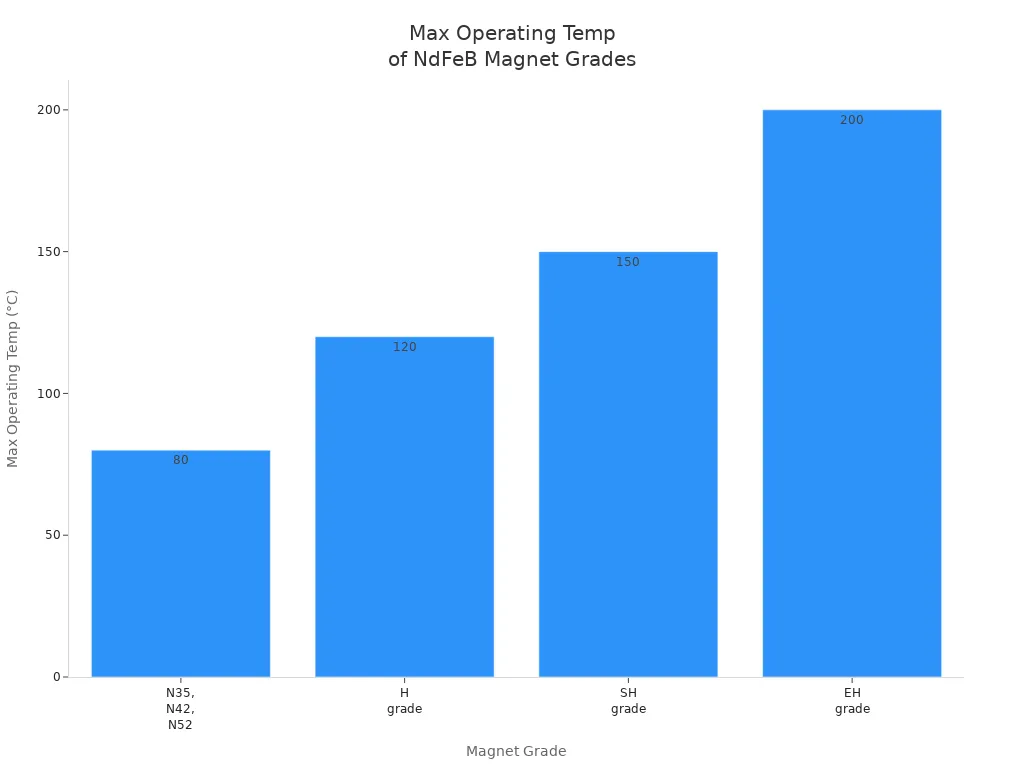

Heat can change how your neodymium magnet works. Regular sintered neodymium magnets start to lose strength above 80°C. If your project gets hot, like in cars or electronics, you need a special magnet grade. Grades like H, SH, and EH are made for high heat. For example, N48SH magnets work up to 150°C. They stay strong in car sensors or machines.

Here is a chart that shows how different grades handle heat:

|

Magnet Grade |

Typical Maximum Operating Temperature |

Application Context |

|---|---|---|

|

N35, N42, N52 (common grades) |

Lower temperature limits (below 80°C) |

General use in motors, electronics |

|

H grade |

Up to 120°C |

Higher temperature resistance applications |

|

SH grade (e.g., N42SH, N48SH) |

Up to 150°C |

Automotive, sensors, high-temperature environments |

|

EH grade |

Up to 200°C |

Demanding high-temperature environments |

If your project faces high heat, always check the magnet’s temperature rating. Picking the right grade keeps your magnet strong and stops it from failing.

Environmental Factors

Where you use your magnet matters a lot. Neodymium magnets do not like water or salty air. Humidity, water, and salt can cause rust and cracks. If your project is outside, near the sea, or in wet places, you need extra protection.

Most sintered neodymium magnets get a coating like nickel-copper-nickel, epoxy, or zinc. These coatings stop rust and keep your magnet strong. For very harsh places, you might need to seal the magnet or use special covers.

Note: Always match the coating to your project. Epoxy and NiCuNi coatings are good for wet or salty places. If you skip this step, your magnet could get weak or break.

Common Application Categories

You can find sintered neodymium magnets in many places. Here are some main uses:

-

Automotive Industry: Electric car motors, power steering, sensors

-

Renewable Energy: Wind turbine generators

-

Medical Devices: MRI machines, diagnostic tools

-

Industrial Automation: Robots, magnetic separators

Each use has its own needs for strength, pull force, size, heat, and environment. If you know these needs first, you will pick the right magnet every time.

Quick Steps to Define Your Application Needs:

-

Decide the pull force and magnetic strength you need.

-

Measure your space and pick the right size and shape.

-

Check the temperature range for your project.

-

Think about water, chemicals, and other factors.

-

Review the details for each magnet.

-

Test a sample if you can.

-

Ask an expert or supplier if you need help.

Knowing your project needs is the most important step. When you know what you want, you can pick the right sintered neodymium magnet and get the best results.

Sintered Neodymium Grades

When you pick a permanent magnet, you should know about sintered neodymium grades. These grades show how strong the magnet is and how it works in different places. If you pick the right grade, your permanent magnet will work better and last longer.

Grade Selection

You will see letters and numbers like N35, N42, or N52 on neodymium magnets. The number after "N" tells you the maximum energy product. This number shows how much magnetic strength the permanent magnet has. Bigger numbers mean the magnet is stronger and works better.

Here are some common grades and where you might use them:

-

N35, N38: Good for simple things, like small motors or toys.

-

N42, N45: Used in electronics, sensors, and some medical tools.

-

N48, N52: Great for strong needs, like electric cars, wind turbines, and special machines.

-

Special temperature grades (like N42SH, N48SH): Good for hot places, like car engines or green energy systems.

The letter after the number (like "SH" in N48SH) shows how much heat the permanent magnet can take. For example, "SH" means it can handle super high heat.

You can look at this table to compare popular neodymium magnet grades:

|

Magnet Grade |

Maximum Energy Product (BHmax) MGOe |

Coercivity (kOe) |

Max Operating Temperature (°C) |

|---|---|---|---|

|

N35 |

35 |

N/A |

N/A |

|

N42 |

42 |

12 |

80 |

|

N42SH |

42 |

20 |

150 |

|

N52 |

52 |

N/A |

N/A |

|

N54-N58 |

54-58 |

Higher (varies) |

Higher (varies) |

A higher maximum energy product means a stronger permanent magnet. If you need a magnet for a hard job, like an electric car or wind turbine, pick a higher grade. If you only need a small magnet for something easy, a lower grade is fine.

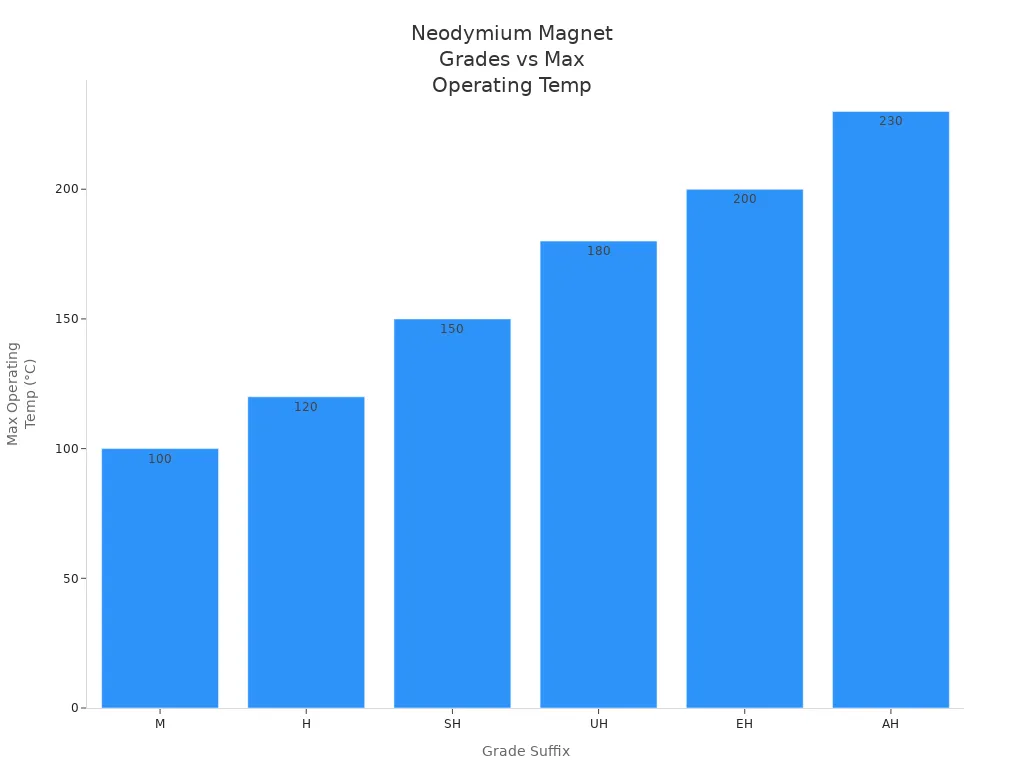

You also need to think about heat. Some permanent magnets get weak when they get hot. The letter at the end of the grade tells you how much heat the magnet can take. Here is a quick guide:

|

Coercivity / Temperature Resistance Description |

Max Operating Temperature (°C) |

|

|---|---|---|

|

M |

Medium coercivity |

100 |

|

H |

High coercivity |

120 |

|

SH |

Super High coercivity |

150 |

|

UH |

Ultra High coercivity |

180 |

|

EH |

Extra High coercivity |

200 |

|

AH |

Advanced High coercivity |

230 |

If you want your permanent magnet to work in a hot place, pick a grade with a higher temperature letter. For example, N42SH can handle up to 150°C, so it works well in cars or machines that get hot.

Cost vs. Performance

You might ask, "Should I always pick the strongest permanent magnet?" Not always! Stronger sintered neodymium magnets cost more money. You need to balance how well it works and how much it costs.

Here is a table to help you see how cost and performance change with different grades:

|

Magnet Grade |

Magnetic Strength (Br in Gauss) |

Price Increase Compared to N35 |

Max Operating Temperature |

Cost-Performance Relationship |

|---|---|---|---|---|

|

N35 |

11700 |

Baseline |

~80°C |

Standard grade, baseline cost and performance |

|

N52 |

14800 |

20-40% higher |

~80-100°C |

Higher magnetic strength, increased cost justified by performance |

|

N35SH |

~11700 |

60% higher |

~150°C |

Same strength as N35 but higher temperature tolerance, higher cost |

If you pick a higher grade, you get better performance, but you pay more. For example, N52 magnets cost about 20-40% more than N35 magnets. If you need a permanent magnet that works in high heat, like N35SH, you will pay about 60% more than a regular N35. The price also goes up if you want a special shape or coating.

Tip: Only choose a high-grade sintered neodymium magnet if your project really needs extra strength or heat resistance. For most simple jobs, a standard grade gives you good performance at a lower cost.

The cost of a permanent magnet depends on more than just grade. Size, shape, and coatings also matter. Raw materials, like rare earth metals, make up most of the price. If you want a special shape or a coating to stop rust, the price can go up by 40-50%. But these features can help your permanent magnet last longer and work better.

When you compare neodymium and ceramic magnets, you will see that neodymium magnets are much stronger in a smaller size. Ceramic magnets cost less, but they are weaker and cannot do hard jobs. Sintered neodymium magnets are best when you need strong, small, and reliable permanent magnets.

So, always match the grade to your needs. Think about how much strength, heat resistance, and durability you need. Then, balance the cost with the performance you want. This way, you get the right permanent magnet for your project without spending too much.

Magnet Coatings

Corrosion Protection

You need to think about corrosion when using a neodymium magnet. These magnets are very strong, but they can rust fast if not protected. Even a little water or salty air can hurt your magnet. If rust starts, the magnet gets weak and might break. You want your neodymium magnets to last a long time, so you need a good coating.

A coating works like a shield. It keeps water, chemicals, and air away from the magnet. With the right coating, your neodymium magnet can stay strong for 30 to 50 years, even in tough places. If you do not use a coating, your magnets will not last long. They could stop working in just a few months, especially in wet or humid places.

Tip: Always check the coating before you buy a neodymium magnet. The right coating helps your magnet stay strong and safe.

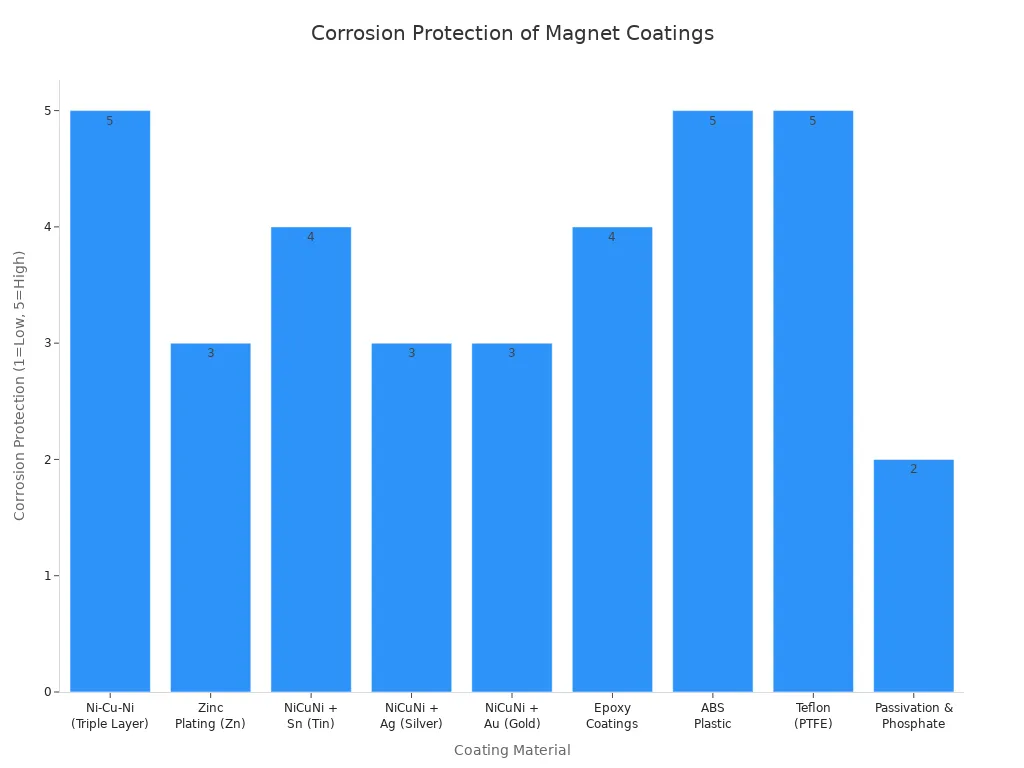

Here is a chart that shows how well different coatings protect neodymium magnets from rust:

Coating Types

There are many coatings you can pick for neodymium magnets. Each one has its own good points. Some work better in wet places, while others are best for dry or indoor use. Let’s look at the most common coatings and what they do for your magnet:

|

Coating Material |

Typical Thickness |

Corrosion Protection Effectiveness |

Additional Properties and Notes |

|---|---|---|---|

|

Ni-Cu-Ni (Triple Layer) |

10-20 µm |

High corrosion resistance; excellent humidity and heat resistance; withstands high pressure and aging tests |

Maintains magnetic properties; widely used; provides electromagnetic shielding; suitable for harsh environments |

|

Zinc Plating (Zn) |

5-8 µm |

Moderate corrosion resistance; self-sacrificing but prone to surface powdering and discoloration under contamination |

Less durable than nickel; better for mild corrosion environments; color zinc coatings improve resistance over blue-white zinc |

|

NiCuNi + Sn (Tin) |

10-25 µm |

Good corrosion protection with added weldability and electrical contact properties |

Used where weldability and electrical contact are required |

|

NiCuNi + Ag (Silver) |

10-20 µm |

Good appearance and weldability; moderate resistance to discoloration |

Suitable for electrical contact applications |

|

NiCuNi + Au (Gold) |

10-20 µm |

Good decoration and color stability; relatively expensive |

Used for decorative and electrical contact purposes |

|

Epoxy Coatings |

10-30 µm |

Good moisture, heat, and salt spray resistance |

Provides excellent adhesive bond; used in demanding applications like wind turbines |

|

ABS Plastic |

Variable |

High corrosion resistance |

Applied by injection molding; available in multiple colors |

|

Teflon (PTFE) |

Variable |

High corrosion resistance and slipperiness |

Suitable for harsh environments |

|

Passivation & Phosphate |

1-3 µm |

Temporary corrosion protection |

Used as temporary coatings before permanent coatings |

Nickel coatings, like the triple-layer Ni-Cu-Ni, are the most popular for neodymium magnets. They make the magnet shiny and protect it from rust, heat, and pressure. If you need a magnet for a wet or salty place, epoxy coatings are a good choice. They make a thick, tough layer that keeps water out. Zinc coatings cost less, but they do not last as long in hard conditions.

If you want your neodymium magnet to last, pick a coating that matches your environment. For outdoor or marine use, choose epoxy or Teflon. For indoor or dry places, nickel or zinc may be enough.

With the right coating, your neodymium magnets will stay strong, safe, and reliable for many years.

Magnetization Direction

When you choose a neodymium magnet, you need to know how it is magnetized. The way the magnet is magnetized changes how it works in your project. There are two main types: axial and radial. Each type gives a different magnetic field and is good for different jobs.

Axial vs. Radial

Axial magnetization means the north and south poles are on the flat ends. If you look at a disc or cylinder magnet, the poles are on the top and bottom. The magnetic field goes straight from one end to the other. This is good when you want the magnet to pull or push in a straight line. People use axially magnetized neodymium magnets in sensors, speakers, and holding tools.

Radial magnetization is not the same. Here, the poles are around the edge of the magnet. The magnetic field moves out or in from the center, like the spokes of a wheel. This type is best for spinning machines, motor rotors, and magnetic encoders. Radially magnetized neodymium magnets give a smooth field all around the edge.

Here is a table to show the differences:

|

Aspect |

Axially Magnetized Magnets |

Radially Magnetized Magnets |

|---|---|---|

|

Magnetization Direction |

Along the height (top to bottom) |

Along the radius, outward or inward from center |

|

Magnetic Pole Location |

Poles at the two end faces |

Poles around the circumference |

|

Magnetic Field Distribution |

Field lines go from one end to the other |

Field lines radiate outward or inward along the radius |

|

Typical Applications |

Sensors, speakers, linear holding, push-pull actions |

Motor rotors, encoders, angle detection, Hall sensors |

|

Manufacturing Complexity |

Easier, less expensive |

More difficult, needs custom fixtures |

Tip: If your magnet needs to spin, pick a radial type. For pulling or pushing in a line, use axial.

Assembly Considerations

Always check the magnetization direction before building your project. If you use the wrong type, your neodymium magnet might not work right. Axially magnetized magnets are easy to stack or line up. They fit well in simple builds. Radially magnetized neodymium magnets need special holders. Their field wraps around the edge, so they need extra care.

When you put neodymium magnets in motors or sensors, the direction is very important. If you mix up the magnetization, your device could lose power or stop. Always ask your supplier about the magnetization direction. You can also test a sample to see how the field moves.

Note: The right magnetization direction makes your neodymium magnet safer and more reliable. It also helps you get the best results from your magnets.

Permanent Magnet Quality

If you want your project to work well, you need a good permanent magnet. Not every magnet is made the same way. Some magnets are stronger and last longer than others. You can tell if a permanent magnet is high quality by checking the supplier and their certifications.

Supplier Selection

Choosing the right supplier is very important. You want a supplier who knows how to make permanent magnets from start to finish. Here are some things to look for:

-

See if the supplier has certifications like ISO 9001, ISO 14001, or RoHS. These show they care about quality and the environment.

-

Ask about how they make their magnets. Good suppliers use pure materials and special methods like strip casting and jet milling. This helps the permanent magnet stay strong.

-

Make sure they have their own sintering and plating workshops. This means they control every step and do not just buy unfinished magnets.

-

Look for suppliers who test every permanent magnet. They should use salt spray and stress tests to check for rust and strength.

-

See if they can make custom magnets for you. A good supplier will help you get the right permanent magnet for your project.

-

Read reviews and talk to other customers. You want a supplier who delivers magnets on time and has a good reputation.

Tip: A good supplier will answer your questions fast and help you fix problems. Good communication helps you get the right permanent magnet every time.

Certifications

Certifications show that a permanent magnet meets strict rules. In the car industry, IATF 16949 is very important. This standard proves the permanent magnet is safe and works well in cars. For electronics, look for ISO 9001 and RoHS. These mean the permanent magnet is made with care and does not have harmful stuff.

Here is a table to help you remember:

|

Certification |

What It Means |

Where It Matters |

|---|---|---|

|

ISO 9001 |

Quality management |

All industries |

|

ISO 14001 |

Environmental management |

All industries |

|

RoHS |

No harmful substances |

Electronics, general |

|

IATF 16949 |

Automotive quality |

Automotive industry |

When you see these certifications, you know your permanent magnet will last and work well. Always ask your supplier for proof before you buy a magnet.

Testing and Consultation

Application Testing

You want your magnet to work perfectly in your real-world application. The best way to make sure is to test it before you use it in your final product. Testing helps you spot problems early and gives you confidence that your magnet will last.

Here are some smart steps you can follow when testing a sintered neodymium magnet:

-

Check the size and shape with special measuring tools. This makes sure your magnet fits your design.

-

Measure the magnetic strength using a gaussmeter or Hall-effect probe. You want to see if the magnet is strong enough for your application.

-

Test the pull force by attaching the magnet to a metal surface and seeing how much force it takes to pull it off. This shows how well it will hold in real life.

-

Look at the coating. Try scratch or tape tests to see if the protective layer stays on. A good coating keeps your magnet safe from rust.

-

Put the magnet through temperature changes. Heat it up and cool it down to see if it still works. This is important if your application gets hot or cold.

-

Spray the magnet with salty water or keep it in a humid place. This checks if it can handle tough environments.

-

Keep records of all your tests. Good notes help you track quality and solve problems later.

Tip: Always test a sample magnet in your actual application before you order a big batch. This saves you time and money.

Expert Advice

Sometimes, you might not know which magnet is best for your project. That’s when you should talk to a magnet expert or engineer. They can help you pick the right magnet and avoid mistakes.

-

Ask your supplier for advice. Good suppliers know a lot about magnets and can answer your questions.

-

Share details about your application, like size, temperature, and environment. The more they know, the better they can help.

-

If you have special needs, like a custom shape or coating, experts can suggest the best options.

Note: Getting advice from a magnet expert can help you avoid costly errors and make your application work better.

Common Mistakes

When you pick a sintered neodymium magnet, it’s easy to make mistakes. Some of these mistakes can cost you time, money, or even your whole project. Let’s look at two of the most common slip-ups and how you can avoid them.

Overlooking Environment

You might think your magnet will work anywhere, but that’s not true. The environment around your magnet matters a lot. If you ignore things like moisture, chemicals, or extreme temperatures, your magnet can lose its strength fast. Water and salty air can cause rust. Chemicals can eat away at the surface. High heat can make the magnet weak or even ruin it.

If you skip coatings like nickel, epoxy, or gold, your magnet might not last. Without protection, magnets in wind turbines, cars, or factories can wear out quickly. You’ll see cracks, rust, or a drop in magnetic strength. Always match your magnet’s coating to where you plan to use it.

Ignoring Long-Term Needs

You want your magnet to work well today, but you also need it to last. If you forget about long-term needs, you could face big problems later. For example, if you use a magnet in a hot place but don’t check its temperature rating, it might lose its strength or stop working. Some magnets can’t handle high heat. Others break if they face too much stress or shock.

Here are some things that can go wrong if you ignore long-term needs:

-

The magnet loses strength if it gets too hot.

-

Rust forms if you skip the right coating, making the magnet weak.

-

The magnet chips or breaks if it faces too much force.

-

Strong outside magnets or heat can cause demagnetization.

-

Poor handling or the wrong environment can lead to cracks and short life.

Think about how your magnet will be used over time. Pick the right grade, coating, and shape for your project. This way, your magnet keeps its strength and lasts longer.

If you avoid these mistakes, you’ll get the best performance and value from your sintered neodymium magnets.

Quick Checklist

Step-by-Step Review

You want to make sure you pick the right sintered neodymium magnet. Here’s a simple step-by-step review you can follow before making your final choice:

-

Check the Alloy and Casting

Make sure the magnet comes from a high-quality alloy. Rapid cooling during strip casting helps prevent weak spots. -

Look at the Powder Quality

The magnet should be made from fine powder. This helps the grains line up and gives you better magnetic strength. -

Review Pressing and Alignment

The powder must be pressed under a magnetic field. This step makes sure the magnet will work as expected. -

Confirm Sintering and Heat Treatment

The magnet should be dense and free from holes. Good heat treatment boosts strength and keeps the magnet stable. -

Check Machining and Edges

The magnet should have smooth edges. This prevents chipping and helps coatings stick better. -

Ask About Magnetization

The magnet needs a strong magnetic field to reach full power. Make sure the supplier uses the right process. -

Test and Classify

Reliable suppliers test magnets for strength and consistency. They should share these results with you. -

Inspect the Coating

A good coating protects against rust. Pick the right one for your environment.

Tip: Always ask your supplier about each step. This helps you avoid surprises and get the best magnet for your needs.

Key Questions

Before you buy, answer these key questions to make sure you have the right magnet:

-

What magnetic strength do you need for your project?

-

Will the magnet face high temperatures? What is the maximum temperature it will reach?

-

Does your environment have moisture, salt, or chemicals? What level of corrosion resistance do you need?

-

What magnet grade (like N35, N42, N52) fits your strength and temperature needs?

-

What shape and size work best for your application?

-

Is the cost within your budget?

-

Can you trust your supplier to deliver quality magnets every time?

-

What type of coating will protect your magnet best?

-

Do you need high coercivity for tough environments?

-

Have you tested a sample magnet in real conditions?

If you can answer these questions, you’re ready to choose the ideal sintered neodymium magnet for your project!

You can pick the perfect sintered neodymium magnet by following a few simple steps. Start by matching the magnet’s strength, grade, and coating to your project. Use the checklist to double-check your choices. Remember, these magnets are the strongest and work best when you balance power, durability, and cost. If you feel stuck, reach out to a supplier or magnet expert. They can help you find the right fit and make sure your magnet meets all safety and quality standards.

FAQ

What makes sintered neodymium magnets so strong?

Sintered neodymium magnets use rare earth materials and a special process that packs the particles tightly. This gives you a magnet with powerful pull in a small size.

Can you cut or drill a neodymium magnet at home?

You should not try to cut or drill these magnets. They are very brittle and can break or chip. The dust is also dangerous. Always order the size and shape you need.

How do you store neodymium magnets safely?

Keep your magnets apart and away from electronics, credit cards, and kids. Use spacers or keepers if possible. Store them in a dry place to prevent rust.

Do neodymium magnets lose strength over time?

If you use them in normal conditions, these magnets keep their strength for many years. High heat, strong impacts, or corrosion can make them weaker.

Are neodymium magnets safe to use around electronics?

You need to be careful. These magnets can damage hard drives, credit cards, and some medical devices. Keep them away from sensitive electronics to avoid problems.

Ratchet straps are versatile and essential tools for securing cargo during transportation, ensuringthat it remains stable and safe throughout the journey. Understanding the correct way to tie down a ratchet strap is crucial for ensuring the security of the load being transported. In this blog post, we will discuss the step-by-step process of properly tying down a ratchet strap to secure your cargo effectively.

How to Tie Down a Ratchet Strap

Before you begin, ensure that the ratchet strap is free of any twists or knots. Check the strap for signs of wear or damage that could compromise its strength. Inspect both the strap and the ratchet mechanism to ensure they are in good working condition.

Position the cargo on the vehicle or platform and locate suitable anchor points to attach the ratchet straps. Anchor points should be sturdy and secure to withstand the tension applied by the ratchet straps during transportation.

To thread the ratchet strap, follow these steps:

1. Pull the loose end of the strap through the mandrel of the ratchet mechanism.

2. Pull the strap tight to remove any slack, ensuring that it is positioned flat and not twisted.

3. Position the strap over the cargo and take the loose end under the anchor point, then back up and feed it through the mandrel of the ratchet again.

Operate the ratchet handle to tighten the strap. With each stroke of the handle, the strap will tighten around the cargo. Ensure that the strap is securely fastened and that there is no slack that could lead to movement during transit.

Once the strap is tightened to the desired tension, lock the ratchet mechanism to prevent accidental loosening. Some ratchet straps feature a locking mechanism or handle that secures the strap in place.

After tightening the ratchet strap, secure the loose end by tying it off or using Velcro straps to prevent it from flapping during transit. This helps to maintain a neat and secure strapping arrangement.

Before moving the cargo, perform a final check to ensure that the ratchet straps are securely fastened, and the load is stable. Check the tension of the straps and confirm that they are evenly distributed to prevent shifting during transport.

By following these steps and ensuring that the ratchet straps are correctly applied and securely fastened, you can effectively tie down your cargo for safe and secure transportation. Properly secured loads help prevent accidents, damage, and ensure a smooth and worry-free transport experience.

In lifting and rigging operations, safety is a strict requirement.

In the United States, the Occupational Safety and Health Administration (OSHA) has established clear regulations for sling use to protect workers and prevent accidents.

Any business that uses slings for hoisting, lifting, or material handling must understand and follow these standards.

1. Overview of OSHA Sling Standards

The main OSHA regulations for slings are found in:

-

29 CFR 1910.184 – General Industry

-

29 CFR 1926.251 – Construction

These cover:

-

Types of slings (synthetic web, synthetic round, wire rope, alloy steel chain, etc.)

-

Design and manufacturing requirements

-

Inspection and removal from service

-

Safe operating practices

-

Identification and labeling requirements

The purpose is to ensure slings are used within their rated capacity, remain in good condition, and are handled by trained personnel.

2. Identification and Labeling

Each sling must have a permanent tag showing:

-

Manufacturer’s name or trademark

-

Rated load for each hitch type (vertical, choker, basket)

-

Material type

-

Length and width (for synthetic slings)

-

Any warnings or limitations

If the tag is missing or unreadable, the sling must be removed from service until proper identification is restored.

3. Inspection Requirements

Slings must be inspected regularly for wear, damage, or defects.

For synthetic web and round slings, check for:

-

Cuts, fraying, or broken stitching

-

Burns or chemical damage

-

Knots or severe abrasion

-

UV degradation

Inspection frequency:

-

Visual check before each day’s use

-

Periodic inspection based on service conditions

Any sling showing signs of damage must be removed from service immediately.

4. Safe Use Practices

To comply with OSHA requirements:

-

Never exceed the Working Load Limit (WLL)

-

Avoid shock loading

-

Use corner protectors or padding at sharp edges

-

Store slings in a dry, clean place, away from sunlight and chemicals

-

Use slings only for their intended purpose

5. Importance of Compliance

Following OSHA standards prevents accidents, reduces equipment damage, and protects workers.

Non-compliance can result in fines, project delays, and legal liability.

How are the inlet and outlet pressures produced of the Rotary lobe pump?

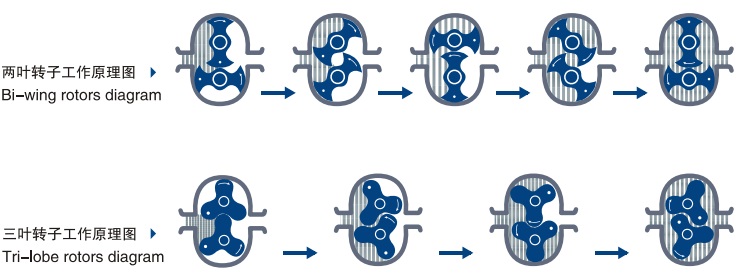

The inlet and outlet pressures of a rotary lobe pump are generated through the cyclic volumetric changes of its sealed working chambers and the positive displacement of fluid by the intermeshing lobes. Here’s a detailed breakdown of the mechanism:

1. Core Structure: The Basis of Pressure Generation

A rotary lobe pump consists of:

· Two counter-rotating lobes (cam-shaped rotors) with precise meshing.

· A stationary pump casing that forms a tight seal with the lobes, creating multiple enclosed "working chambers" between the lobes and the casing.

These working chambers are critical—their volume expands and contracts as the lobes rotate, driving fluid movement and pressure changes.

2. Inlet Pressure: Negative Pressure from Volume Expansion

At the inlet (suction side), pressure is generated by the expansion of the working chambers, which creates a low-pressure zone to draw fluid in:

1. As the lobes rotate, they separate at the inlet region, causing the volume of the working chambers in this area to increase rapidly.

2. According to the principle of volumetric displacement, the expanding volume reduces the pressure inside the chambers (below atmospheric pressure or the upstream system pressure).

3. This negative pressure (suction) overcomes the resistance in the inlet pipeline, pulling fluid into the chambers until they are fully filled (when the lobes are maximally separated).

Key Note: Inlet pressure is typically slightly below atmospheric pressure. Its magnitude depends on inlet line resistance (e.g., pipe length, bends, fluid viscosity)—higher resistance requires a stronger negative pressure to draw fluid effectively.

3. Outlet Pressure: Positive Pressure from Volume Contraction

At the outlet (discharge side), pressure is generated by the contraction of the working chambers, which forces fluid out under pressure:

1. As the lobes continue to rotate, the filled working chambers move toward the outlet. Here, the lobes re-mesh, causing the chamber volume to decrease sharply.

2. Since fluids are nearly incompressible, the shrinking volume compresses the trapped fluid, increasing the pressure inside the chambers.

3. When the lobes fully mesh, the working chambers collapse completely, forcing the pressurized fluid out of the outlet into the discharge pipeline—creating outlet pressure.

Key Note: Outlet pressure is determined primarily by the resistance of the downstream system (e.g., pipe friction, elevation, backpressure from equipment). Higher downstream resistance requires greater pressure to push fluid through, and the pump maintains this pressure by continuing to reduce chamber volume.

4. Sustaining Pressure: Sealing and Continuous Operation

Stable inlet and outlet pressures rely on two critical factors:

· Tight Sealing: Minimal clearance (typically 0.1–0.5 mm) between the lobes and casing, and between the lobes themselves, prevents fluid leakage. Leakage (e.g., high-pressure fluid from the outlet flowing back to the inlet) would reduce pressure differentials and efficiency.

· Continuous Rotation: The lobes’ constant rotation ensures overlapping cycles of chamber expansion (suction) and contraction (discharge), delivering a steady flow and maintaining consistent pressure levels (minimizing pulsation).

Summary

The pressures in a rotary lobe pump arise from the dynamic volumetric changes of its working chambers:

· Inlet pressure is a negative pressure (suction) created by expanding chambers, drawing fluid in.

· Outlet pressure is a positive pressure generated by contracting chambers, forcing fluid out.

· Both pressures are balanced against system resistance (inlet resistance for suction, downstream load for discharge) and sustained by tight sealing and continuous rotation.

This mechanism makes rotary lobe pumps ideal for high-viscosity, shear-sensitive, or solids-laden fluids, as they rely on positive displacement rather than centrifugal force.

Many industrial operators face significant challenges when transferring liquid sulfur, particularly with equipment reliability. A common frustration is the rapid failure of gear pumps—often within just 30 hours of operation—due to sulfur solidification and pump corrosion. Let's explore why this happens and how BONVE's specialized rotary lobe pumps provide a superior solution.

The Problem: Why Gear Pumps Fail with Liquid Sulfur

Liquid sulfur presents unique handling challenges that expose critical limitations in standard gear pump designs:

1. Solidification Risks With a melting point of 115-120°C, liquid sulfur rapidly solidifies into hard lumps when cooled. Gear pumps' tiny operational clearances (0.05-0.2mm) get easily blocked by solidified sulfur, causing jamming or catastrophic damage during forced operation.

2. Corrosive & Abrasive Nature High-temperature liquid sulfur corrodes common steels, while impurities (unmelted sulfur, rust particles) act as abrasives—accelerating wear on gear surfaces and bearings.

3. Design Misalignment Gear pumps rely on precise clearances and media lubrication—both problematic for sulfur. Their seals often fail under high temperatures, allowing air ingress that further accelerates sulfur solidification.

4. Operational Vulnerabilities Inadequate insulation, improper shutdown procedures, or insufficient preheating exacerbate these issues, leading to premature failure.

BONVE's Engineered Solution: Rotary Lobe Pumps for Liquid Sulfur

Our rotary lobe pumps are specifically designed to address liquid sulfur's unique challenges, delivering extended service life through these critical features:

· Superior Material Construction Duplex 2205 stainless steel provides exceptional resistance to sulfur's corrosive effects and abrasive particles.

· High-Temperature Sealing FFKM O-rings withstand operating temperatures up to 200°C, maintaining integrity where standard rubber compounds fail.

· Reliable Shaft Sealing Single-face mechanical seal without flushing minimizes potential failure points while preventing sulfur leakage.

· Integral Temperature Control Heating jackets on both casing and cover maintain optimal sulfur temperature, preventing solidification.

· Operational Safeguards (End-user responsibility) Full preheating before restart ensures smooth operation and prevents damage from solidified sulfur.

Application Example

For a typical liquid sulfur transfer application (200°C, 10m³/Hr, 4 Bar), we recommend Rotary Lobe Pump model 80BV12-20 :

|

Parameter |

Specification |

|

Model |

65BV12-20 |

|

Displacement |

1.56L/r |

|

Rotor Type |

Bi-wing rotor |

|

Contact Material |

Duplex 2205 |

|

Seal Configuration |

Single Face Mechanical Seal |

|

Inlet/Outlet Size |

DN80/DN80 (Flanged) |

|

Drive System |

Geared reducer + 11kW motor |

|

Recommended Speed |

250r/min |

Why Choose BONVE for Liquid Sulfur Transfer?

Our rotary lobe pumps' robust design, larger operational clearances, and sulfur-specific materials overcome the limitations of gear pumps. By addressing the root causes of failure—solidification, corrosion, and design constraints—BONVE pumps deliver reliable performance for liquid sulfur applications.

Contact our technical team today to discuss your specific liquid sulfur transfer requirements and discover how BONVE's solutions can reduce downtime and maintenance costs.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2